Good Material eco friendly material roll polypropylene nonwoven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good Material eco friendly material roll polypropylene nonwoven fabric

Product Description

Brief Introduction :

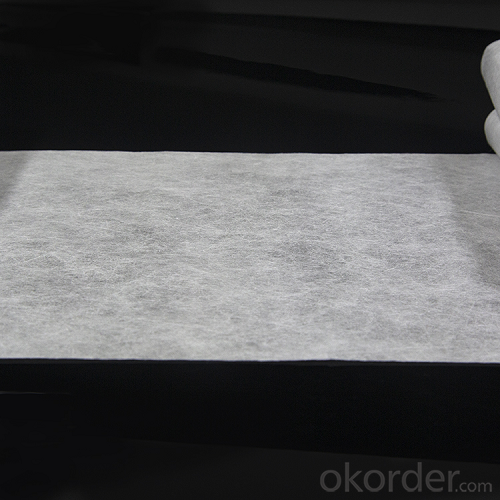

Melt-blown non-woven fabric uses PP as the main raw material, through melt spinning, and is blown by a high-speed hot air flow at a certain angle on both sides of the nozzle to stretch, blow, and fall the fiber into a net, and most of them are formed by self-bonding.

The products has the following characteristics:

Fiber diameter can reach 1 ~ 5 microns, high filtration efficiency;

More voids, fluffy structure, low resistance;

The fiber net has good uniformity and soft touch

Specifications:

| Product name | Melt Blown Fabric |

| Material | 100%PP |

| Technics | Meltblown nonwoven fabric |

| Thickness | Customized nonwoven fabric |

| Width | 170-260mm customized |

| Color | Customized |

| Length | 50m,100m,150m,200m or customized |

| Packaging | Carton or customized |

| Payment | T/T,L/C |

| Delivery time | 10 days after receiving buyer's payment |

| Price | Reasonable price with high quality |

| Capacity | 3Tons per 20ft container;

5Tons per 40ft container;

8Tons per 40HQ container. |

Caracterics:

Static attraction prevents germs from invading.

Good flame retardant performance

Good permeability and shielding property

High efficiency low resistance

Achieve FFP3 Level KF94 Level

Detailed of our product:

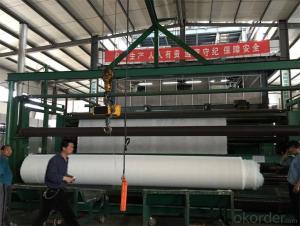

Produce Process

Step 1:

Incoming material quality inspection, the drum is preheated and the temperature is set, and then it is introduced into the glue tank of the corresponding glue setting equipment, and the silk non-woven fabric is pressed along the machine's motion track.

Step 2:

The silk floss conveyed by the upper track passes through the glue roller area, and then the non-woven fabric conveying zone and silk floss are delivered to the high temperature hot pressing roller zone.

Step 3:

Applies the non-woven fabric to the composite cotton and then rolls the fabric needs to make a batch and cut it off.

Step 4:

Timely transportation.

Application

Shopping bags,tablecloth,compund packing material,Filter material

Medical field :Face mask Surgical gown,protective clothes,operation cover,cap,shoe cover,bed sheet etc.

Sanitary and Health:Baby&adult diaper,feminie hygiene,hygiene pad,etc

Agriculture and horticulture cover

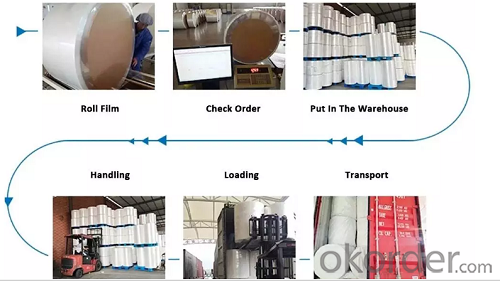

Packing and Shipping

FAQ

Q1. Samples?

A1. We offer free samples but courier fees at your cost.

Q2. Do you have MOQ?

A2. One ton for any colors fabric , any qty on white and black.

Q3. What is your delivery time ?

A3. Around 5 days depend which products, please confirm with sales rep.

Q4.Payment terms?

A4. TT, LC at sight , DP are all acceptable / negotiable and case to case.

Q5. CIF / FOB / EXW etc..

A5. Pls send destination port for quote on CIF.

Q6. Shipping

A6: Air freight cargo or sea shipment.

- Q: What are the advantages of modal fabric?

- Modal fiber is characterized by the natural fiber luxury texture and synthetic fiber combination of practicality. With the soft cotton, silk luster, Ma's smooth, and the water absorption and air permeability are better than cotton, has high dyeing rate, fabric color bright and full. Modal fiber and multiple fiber blended and interwoven, such as cotton, linen and silk, in order to improve the quality of the cloth, the fabric can keep soft and smooth, play to their respective fiber characteristics, to better take effect. 1, Modal fiber fabric, soft, good drape, comfortable to wear. 2, Modal fiber fabric moisture absorption and permeability better than pure cotton fabric, is ideal for close knit fabric and health care clothing products, is conducive to human physiological cycle and health. 3, Modal fiber fabric surface, smooth and delicate, with natural silk effect. 4, Modal fiber fabric bright colors, light amount, is a natural mercerized fabric. 5, Modal fiber fabric has stable performance, tested compared with the cotton fabric after 25 times washing, feel will become increasingly hard, while the Modal fiber fabric on the contrary, modal fabric after washing many times, still keep the original smooth and soft feel, soft and bright, and more wash more soft, more wash the more beautiful. 6, Modal fiber fabric garment effect, shape stability, has the natural crease resistance and easy care, make people more convenient and natural.

- Q: What exactly is the ingredient of iced silk fabric?

- Only know that the ice silk is silkworm vomit silk, ice lint do not know what thing, haven't heard. The ice is what we usually say the artificial silk is a kind of man-made fiber blends, generally used for summer sweaters, features good drape, touch smooth, cool skin. The disadvantage is sweat poor, crisp feeling bad, not high temperature.Silk is polyester, good air permeability. Wearing a sense of Bing Bing, wearing a habit of words can also. The cotton has good breathability and sweat absorption.

- Q: What fabric is Lurex?

- Wire line "commonly known as" gold and silver, gold and silver decorations made of silk wire for weaving "by chemical method. Due to the gold and silver two, hence the name." "" line "is used to call, is no actual twist piece wire. Ancient gold and silver silk is gold and silver by hand into a thin foil, mounted in the thin sheepskin or paper, then cut into a filamentous, known as the" gold "," silver "flat expensive components, a thick and hard line, easy to wear, easy to change color.The common varieties of modern gold and silver wire are made of polyester film and made by vacuum transition LI. The.20 century originated in the United States in the early 50s, and our country began to produce industrial production in 70sThe gold and silver wire, now fine, soft, light, bright colors, the price at the end. There are: 1 polyester, gold and silver thread, single-layer polyester film vacuum Du LI, resin coated with protective film, used for dyeing fabric, 2, composite gold and silver thread, polyester film of the two layer, a layer of foil clip LI that will be used for dyeing fabrics, 3, and round type gold and silver line with stage clothing, clothing now (Fashion).4, in addition to the "Rainbow" gold and silver "for flower color fabric, especially decorative fabric"

- Q: What is the fabric of sun velvet?

- Cotton cashmere Yang strong rhombic honeycomb heat storage structure, can reduce the gas flow resistance is greatly improved, the single pore volume of regenerator heat transfer efficiency greatly, efficient storage of a large number of static air, effectively blocking the air flow to every inch of the warm in bed, let the bed warm sun rises.

- Q: What's the difference between nylon and Dacron?

- On the other hand will be different. Polyester feel more rough, feel very smooth nylon. Also can use fingernails, fingernails, there are obvious signs is not obvious traces of polyester, nylon, but this method is better than the first method is intuitive and easy to argue

- Q: What about the Rolle and the uniform? What's the best of these two fabrics?

- The new polyester wire network, the raw material 100% easy shrinkage polyester filament, 1 / 1 plain weave fabric weight, 300G / M, width of 58 inches of fabric appearance, crisp, smooth, comfortable, soft luster, hairy feeling, excellent flexibility, good performance apparel, seasonal strong, suitable for employees and the middle the staff of spring and summer uniform, high strength, good fastness, especially suitable for factories, uniforms and uniforms, and is also suitable for the fashion.What material do you wear? Compare what you want with that kind of clothes

- Q: What fabric is blended?

- Blending means that the ingredients contain two or more than two ingredients, blends, no fixed fabric, many blends, cotton and polyester blends, cotton and brocade blends, TR blends, lots and lots

- Q: What about polyester fabric? How about air permeability?

- Characteristics of polyester fiberStrength: the strength of polyester fiber is nearly 1 times higher than that of cotton, 3 times higher than that of wool, so the polyester fabric is durable.Heat resistance: can be used at 70~170 degrees, is the best in synthetic fiber heat resistance and thermal stability.Elasticity: Polyester Elastic close to wool, wrinkle resistance over other fibers, fabric wrinkle free, good shape.Abrasion resistance: polyester is second only to nylon in abrasion resistance, and occupies second place in synthetic fiber.Water absorption: Polyester moisture regain low, good insulation performance, but because of low water absorption, friction generated by static electricity, dyeing performance is poor.

- Q: What is the difference between TC fabric and cotton fabric?

- Cotton: cloth made from cotton yarn. It is the floorboard of all kinds of cotton textiles. It is used to make fashionable clothes, casual clothes, underwear and shirts. The utility model has the advantages of easy warm, soft close, hygroscopicity, permeability is very good. It is easily the shortcomings shrinkage, easy to wrinkle, the appearance is neat and elegant, dress must constantly pressing.

- Q: 100 what's the fabric of Dacron?

- Dacron has a wide range of uses and is widely used in the manufacture of garments and industrial products. Polyester fiber has excellent shape setting property. Polyester yarn or fabric produced by setting the flat, fluffy form or pleated, in the use of repeated washing, still enduring.

Send your message to us

Good Material eco friendly material roll polypropylene nonwoven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords