Glass Wool Insulation Fiber Glass Wool Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Glass Wool For Insulation Glass Wool Board

1.Structure of Fiber Glass Wool For Insulation Glass Wool Board:

Glass wool with Facing is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. Glass wool is 100% recyclable. It is manufactured from sand and recycled glass(up tp 80% cullet) and offers a very positive environmental balance sheet. It protects the environment, from the beginning to the end of its life cycle and gives more comfort and savings to the occupants of the buildings it insulates.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

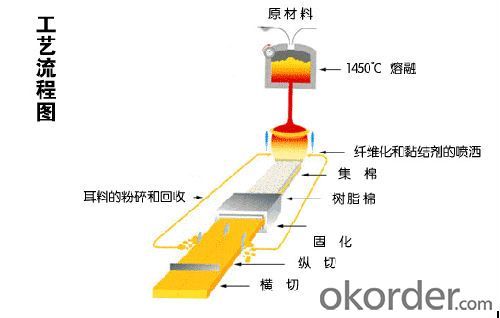

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Fiber Glass Wool For Insulation Glass Wool Board:

The glass wool Blanket with Facing is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

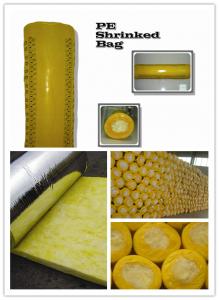

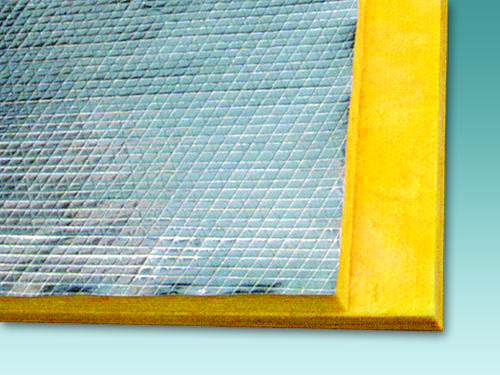

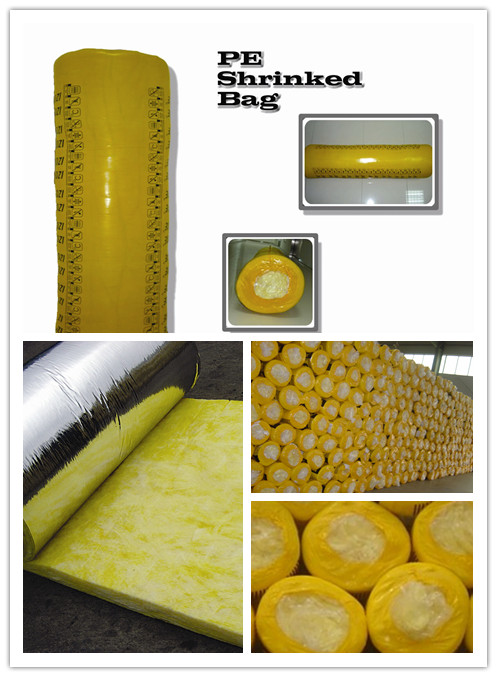

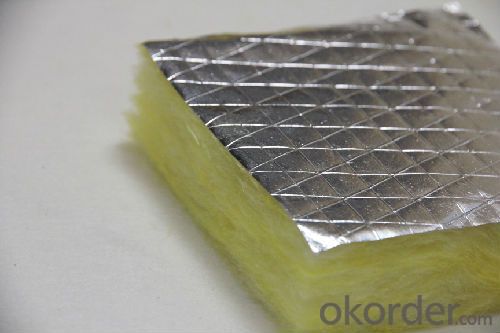

3. Fiber Glass Wool For Insulation Glass Wool Board Images

4. Fiber Glass Wool For Insulation Glass Wool Board Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with Facing surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

- Q: What's the difference between the rock wool and glass wool?

- Glass wool: Main raw material is glass, A level fireproof grade, thermal conductivity coefficient 0.037, thermal shrinkage temperature 270 degrees, application: obvious cold insulation effect. Rock wool: Main raw material is glass, A level fireproof grade, thermal conductivity coefficient 0.040, thermal shrinkage temperature 730 degrees, application: It'd used in construction, ship building, petroleum chemical and other high-end engineering. hope it can help you.

- Q: What are the hazards of glass wool to body?

- Non-environmentally friendly materials, the Olympic venues banned: In view of the glass wool is not environmental factors, the State Ministry of Construction and the Beijing Municipal Health Bureau issued the relevant provisions

- Q: How to distinguish green glass wools?

- It is very simple. First, look the appearance. Glass wool is pure white, not bleached. Bleached glass wool is milk white, and the glass fiber is thorny, white formaldehyde-free glass wool is soft to touch. Second, look at the test report, and verify the authenticity of the test report online. Detection result of formaldehyde-free should be zero or "not detected". If the detection result is 0.1, it can't be formaldehyde-free. So take a closer look at the test report, and do not be deceived . Many manufacturers have bleach the glass wool which is cheap but counterfeit. You get what you pay for. So look carefully.

- Q: Does anyone know about the filling materials in the steel stud, is it glass wool or mineral wool?

- Relatively glass wool of famous brand is more environmentally friendly. Rock wool has larger particles. They all have good thermal insulation and sound absorption performance, but are not recommended to use them both. The proportion of glass wool used is smaller than that of rock wool in terms of the same sound absorption performance. It may contains asbestos.

- Q: Which one is more enviroment friendly, glass wool mat or rock wool sound insulating block?

- Glass wool is mainly used for heat perservation. Glass wool plate is used for sound insulation and its sound insulation performance is rather good. Both rock wool board and glass wool are sound insulating, but they also can not directly contact with human. Therefore, they are used between walls or two things. In terms of environment protection, the glass wool is more environmentally friendly as it is not as itchy as rock wool board when it contacts with people and has less dust than rock wool board. However, it is best not to touch these two materials directly for it is not good for respiratory tract. Even so, the sound insulation effect of two items is still good.Buoya construction materials corporation can produce both prosucts.

- Q: Which is more suitable for industrial pipe insulation: glass wool or rock wool ?

- Glass wool, now rock wool seems to be out of date.

- Q: What are the features of glass wool decorative acoustic?panel?absorber suspended ceiling?

- 1, Excellent decorative effect. Mineral wool acoustic board has various patterns and reliefs, stereoscopic model, reflecting ancient glory and modern fashion, really refreshing. 2. good thermal insulation property. Mineral wool acoustic board is good thermal insulation material which can be make the house warm in winter and cool in summer and save energy for users because it has low heat conductivity coefficient. 3. sound absorption and noise reduction. The main raw material of mineral wool acoustic board is ultra-fine mineral wool fibre whose density is about 200 ~ 450Kg / m, so it has many perforative micropores which can effectively absorb sound waves and reduce sound wave reflection so as to improve indoor tone quality and reduce noise. 4. fireproof. Since the mineral wool is an inorganic material, it will not burn, and mineral wool acoustic board has very low content of organics, thus making it meeting requirements of Class B1 non-combustible. And our products have been able to reach non-combustible Class A . 5. Green and eco-friendly, regulating air. Mineral wool acoustic board does not contain harmful substances. It contains active groups which can absorb harmful gases in the air and its porous structure can absorb and release water molecules so as to purify the air and adjust indoor air humidity . 6. moisture-proof and insulation. Since mineral wool acoustic board contains a large number of micropores and has releatively large surface area, it can absorb and release water molecules in the air and regulate indoor air humidity. It can be regarded as a decorative board that can breath.

- Q: What are the differences between the glass fiber and glass wool? ?

- Glass wool belongs to one of the glass fiber categories, which is a kind of man-made inorganic fiber. The sieve plate can not be replaced by glass fiber, which is a kind of elastic felty body produced by glass fiber whose diameter is only a few microns. Glass wool is a product made by fibering the molten glass and adding environmentally friendly recipe binder which is mainly thermosetting resin, use glass wool

- Q: Does anyone know about the specifications of formaldehyde-free glass?wool?boards?

- It's very simple, first, look at the appearance. The glass wool is pure white, is not bleached. Bleached glass wool is milk white, and the glass fibers will be itchy and prick hands. Formaldehyde-free glass wool will not be itchy and prick hands, it is soft. Second, look at the test report, and identify the authenticity of the test report on the Internet. Formaldehyde-free refers to the detection result is zero or "no detection", even the formaldehyde content is 0.1, it is still not formaldehyde-free, look at the test report carefully. The models of formaldehyde-free glass wool board are: 32KG/50MM, 48KG/50MM, 80KG/50MM, 96KG/25MM, 80KG/25MM,

- Q: What are the industry standards of glass wool and its products?

- The industry standards of glass wool and its products GB / T 13350-2000. The standards specifies classification, requirements, testing methods, inspection rules, marking, labeling, packaging, transportation and storage of glass wool for thermal insulation and its products. It also give the conversion of thermal resistance and thermal conductivity coefficient. This standard applies to insulating glass wool, glass wool board, glass wool band, glass wool blanket, glass wool felt and glass wool tube.

Send your message to us

Glass Wool Insulation Fiber Glass Wool Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords