Glass Fiber Textiles Ceramic Fiber Insulation Wool Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Application: | Refractory | Grade: | ST (Standard) | Working Temperature: | 1050C |

| Place of Origin: | China (Mainland) | Brand Name: | SUNTHERM | Model Number: | SS wire reinforced |

| Certificate: | BV,SGS,CE,ROHS,ISO9001:2000 | Sample: | Available | MDS Availabel: | Yes |

Packaging & Delivery

| Packaging Detail: | Woven bag , carton or as your demand to custom |

| Delivery Detail: | Within 15 days after received the deposit. |

Specifications

Ceramic fiber textile

AL2O3:45%

Fiber diameter:3-5um

Temperature:1050C ISO9000 certificate

ceramic fiber rope includes square braided rope, round braided rope and twisted rope. All are made from high quality ceramic fiber material. The rope is reinforced with fiberglass filament, or alloy steel wire. Fiberglass filament reinforced rope can work in the temperature below 650C with electric insulating property, while alloy steel wire can work in the temperature 1100C with higher strength. Ceramic fiber textiles (cloth, tape and rope) contain a certain amount of binder material which is normally burned at lower temperature and does not affect the insulation property .The three different styles are designed to fit different application needs: twisted rope is a soft rope, while square and round braid are more dense and solid.

Product information

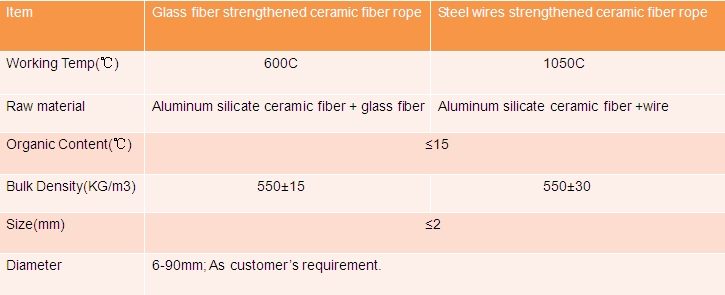

Item | Ceramic fiber rope |

Type | Glass fiber strengthened ceramic fiber rope Steel wires strengthen ceramic fiber rope |

Applications | • High temperature static seal e.g. door joint or gaskets for flanges • Fire protection e.g. fires proof curtain against welding spark. • The protection of cable, fuel tubes etc • Fireproof twine, wrap, cover etc • Pipe or round duct insulation lagging • Asbestos substitute |

Features | •Excellent high temperature stability • Excellent tensile strength • Excellent thermal electrical insulation • Excellent chemical stability resistance • Low thermal conductivity. |

Packing | In plastic bags, in cartons or according customers requirement. |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash. |

Delivery Time | Within 15 days after received the deposit. |

Certificate | ISO9001-2000, ISO14001-2000, CE ,SASO,SGS . |

Technical data

- Q: Can glass fiber textiles be used in protective helmets?

- Yes, glass fiber textiles can be used in protective helmets. Glass fiber textiles are known for their high strength and impact resistance, making them suitable for enhancing the protective capabilities of helmets. They can provide added reinforcement and durability, helping to absorb and distribute impact forces, thereby increasing the overall safety of the helmet.

- Q: Can glass fiber textiles be used in reinforcement of adhesives?

- Glass fiber textiles have the ability to strengthen adhesives. These textiles are well-known for their strength and stiffness, making them an ideal choice for improving the mechanical properties of adhesives. By adding glass fiber textiles to adhesives, the tensile and flexural strength, impact resistance, and overall durability of the adhesive joint can be enhanced. The glass fibers serve as reinforcement by evenly distributing stress across the adhesive, preventing cracks and increasing the load-bearing capacity. Furthermore, glass fiber textiles can improve the dimensional stability and thermal resistance of the adhesive, allowing for a wider range of applications. However, it is crucial to consider the compatibility between the glass fibers and the adhesive matrix, as well as the proper handling and dispersion of the fibers, to ensure optimal reinforcement effectiveness.

- Q: Is glass fiber textile resistant to fire?

- Glass fiber textile exhibits a remarkable resistance to fire. The production process involves the conversion of molten glass into delicate and pliable threads. These threads possess a high melting point and are incapable of sustaining combustion. Consequently, glass fiber textiles are frequently utilized in the manufacturing of fire-resistant garments, curtains, and insulation materials. Their ability to resist ignition and endure extreme temperatures without melting or emitting harmful fumes provides exceptional protection against heat and flames. Moreover, the low thermal conductivity of glass fiber textiles prevents rapid heat transfer, further reinforcing their fire-resistant attributes. In summary, glass fiber textiles prove to be a dependable and efficient choice for situations that necessitate fire resistance.

- Q: Standard for testing fabric thickness?

- The test report shall include the following: the A. declaration test is carried out according to this standard. B. name of woven fabric to be tested and relevant instructions. C. pretreatment time, ambient temperature and relative humidity. Arithmetic mean, standard deviation, and test times of D. thickness. E. any details that affect the results of the test.

- Q: Can glass fiber textiles be used in reinforcement of paints?

- Yes, glass fiber textiles can be used in the reinforcement of paints. Glass fibers are known for their high strength and durability, making them an excellent choice for reinforcing various materials, including paints. When added to paint formulations, glass fiber textiles enhance the overall strength, flexibility, and resistance to cracking or peeling. Additionally, they can improve the paint's adhesion to different surfaces, resulting in a longer-lasting and more durable finish.

- Q: Are glass fiber textiles suitable for sports apparel?

- Sports apparel can indeed benefit from the use of glass fiber textiles. These textiles possess numerous qualities that render them perfect for sports attire. Firstly, their lightweight nature is essential as it allows for unrestricted movement and reduces the burden on the wearer. Moreover, glass fiber textiles possess exceptional strength and durability, making them resistant to the wear and tear associated with vigorous physical activities. Another notable quality of glass fiber textiles is their exceptional ability to wick away moisture. This is crucial for sports apparel as it keeps the wearer dry and comfortable by drawing sweat away from the body. By regulating body temperature and preventing the accumulation of moisture, glass fiber textiles prevent discomfort and chafing. Furthermore, glass fiber textiles offer excellent breathability, facilitating air circulation and preventing overheating. This is particularly important in sports that generate substantial body heat, such as running or cycling. Additionally, glass fiber textiles possess inherent anti-bacterial and anti-odor properties. This makes them resistant to bacterial growth and reduces unpleasant odors that often accompany physical activity. It is important to note, however, that glass fiber textiles may not be suitable for all types of sports apparel. For instance, they may lack the flexibility or stretchiness required for certain sports that demand a high degree of flexibility. Nevertheless, for sports attire that necessitates a balance between strength, durability, moisture-wicking, breathability, and anti-bacterial properties, glass fiber textiles are an excellent choice.

- Q: How do glass fiber textiles compare to ceramic fiber textiles?

- Glass fiber textiles and ceramic fiber textiles are both popular materials used in various applications. However, there are some key differences between the two that should be considered when choosing the appropriate material for a specific project. Strength and Durability: Glass fiber textiles are generally stronger and more durable than ceramic fiber textiles. Glass fibers have a higher tensile strength, meaning they can withstand more stress before breaking. This makes them ideal for applications that require high strength and durability, such as reinforcement in composite materials. Ceramic fibers, on the other hand, are more brittle and can break easily under stress. Thermal Properties: Ceramic fiber textiles have superior thermal properties compared to glass fiber textiles. They have a higher melting point and can withstand much higher temperatures without deforming or degrading. This makes ceramic fibers suitable for applications where high-temperature resistance is crucial, such as insulation in furnaces or kilns. Glass fibers, although they can handle relatively high temperatures, may not be suitable for extremely high-temperature environments. Chemical Resistance: Glass fiber textiles have excellent chemical resistance, making them suitable for applications where exposure to harsh chemicals or corrosive environments is expected. They are resistant to most acids, alkalis, and solvents. Ceramic fibers, on the other hand, are generally not as chemically resistant as glass fibers and may be prone to degradation when exposed to certain chemicals. Insulation Properties: Both glass fiber textiles and ceramic fiber textiles offer good insulation properties. However, ceramic fibers have lower thermal conductivity, meaning they provide better insulation. This makes them suitable for applications that require excellent thermal insulation, such as in the construction of fire-resistant barriers or in high-temperature insulation systems. Cost: In terms of cost, glass fiber textiles are generally more affordable compared to ceramic fiber textiles. This cost advantage makes them a popular choice for a wide range of applications. Ceramic fibers, on the other hand, tend to be more expensive due to their superior thermal properties and higher manufacturing costs. In summary, glass fiber textiles and ceramic fiber textiles have their own unique properties and advantages. Glass fibers are stronger, chemically resistant, and more cost-effective, while ceramic fibers offer superior thermal properties and insulation. The choice between the two depends on the specific requirements of the application, such as strength, temperature resistance, chemical exposure, and budget constraints.

- Q: How do glass fiber textiles affect the drapability of fabrics?

- Glass fiber textiles, also known as fiberglass textiles, can significantly affect the drapability of fabrics. The addition of glass fibers to a fabric can enhance its stiffness and rigidity, making it less likely to drape naturally. This is because glass fibers have a high tensile strength and are relatively inflexible compared to natural or synthetic fibers commonly used in textiles. When glass fiber textiles are incorporated into fabrics, they create a network of interlocking fibers that add structure and stability to the material. This can be desirable in certain applications where a more rigid fabric is desired, such as in industrial or technical textiles. However, in garments or home furnishings where drape and fluidity are important, the presence of glass fibers can be a disadvantage. The stiffness imparted by glass fiber textiles can restrict the movement and flow of the fabric, leading to a less natural drape. Fabrics with glass fibers may not hang as smoothly or gracefully as those without, and may appear more stiff and rigid when worn or used in drapery. Additionally, the presence of glass fibers can affect the feel and texture of the fabric, making it potentially less comfortable against the skin. It is worth noting that the extent to which glass fiber textiles affect drapability can vary depending on the concentration and distribution of the fibers within the fabric. Higher concentrations of glass fibers or a more densely woven or knitted structure will generally result in a more pronounced impact on drapability. Overall, while glass fiber textiles can offer certain benefits in terms of strength and stability, they can have a negative impact on the drapability of fabrics. It is important for designers and manufacturers to consider the intended application and desired characteristics of a fabric when deciding whether to incorporate glass fibers or opt for other alternatives.

- Q: Are glass fiber textiles resistant to wrinkling?

- Yes, glass fiber textiles are generally resistant to wrinkling. Glass fibers are known for their inherent strength and rigidity, which helps to maintain the shape and structure of textiles made from them. Additionally, glass fibers have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with changes in temperature, further contributing to their wrinkle-resistant properties. This makes glass fiber textiles highly durable and less prone to wrinkling compared to other materials. However, it is important to note that the overall wrinkle resistance of a textile can also depend on factors such as the specific weave or construction of the fabric, as well as the finishing treatments applied to it.

- Q: How do glass fiber textiles resist chemicals?

- Glass fiber textiles possess exceptional chemical resistance due to the inherent properties of glass fibers themselves. The resistance stems from the fact that glass, composed of inorganic materials like silica, is highly unreactive to chemicals. The tightly packed molecules in the structure of glass fibers create a network of interconnected bonds, forming a barrier that prevents chemicals from penetrating or permeating the fabric. Consequently, glass fiber textiles effectively withstand the corrosive effects of various chemicals, including acids, alkalis, and solvents. Moreover, glass fibers exhibit a high melting point, typically around 1500°C (2732°F), rendering them highly heat resistant. This quality further enhances their chemical resistance, as glass fiber textiles remain stable and undergo minimal degradation or chemical reactions even under high temperatures. Additionally, glass fiber textiles are non-flammable, meaning they do not support combustion. This characteristic is especially significant when dealing with flammable or heat-reactive chemicals. It is important to mention that the chemical resistance of glass fiber textiles can vary based on the specific type of glass fiber used and the manufacturing process. Some glass fibers may undergo additional coatings or finishes to augment their chemical resistance properties. Overall, the distinctive composition and structure of glass fiber textiles lend them high chemical resistance. Consequently, they find suitability in a wide range of applications, including protective clothing, filtration, and insulation in industries where exposure to chemicals is a concern.

Send your message to us

Glass Fiber Textiles Ceramic Fiber Insulation Wool Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords