Geonet High Strength Non Woven Polypropylene Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

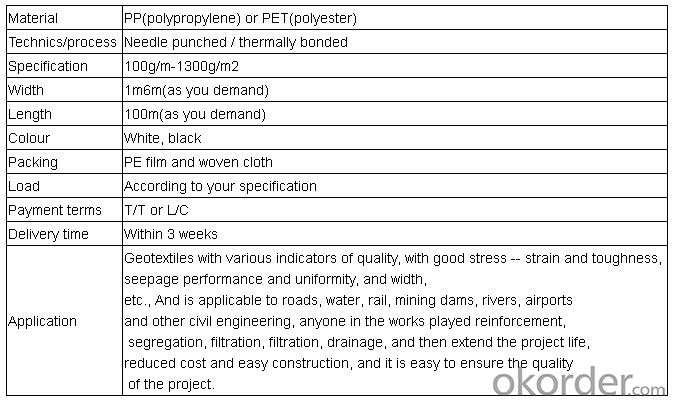

Specifications:

1, Biggest Width: 6meter

2, Weight: about 90 gram to 800 gram

3, Treatment: UV protect

Application:

A: Subsurface drainage

B: Roadway separation

C: Hard armor underlayment

D:Asphalt overlay applications

Specification :

Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the different design considerations for geotextile applications?

- Some of the different design considerations for geotextile applications include the type and properties of the geotextile material, the site conditions and requirements, the desired functions and performance criteria, the installation and construction methods, and the long-term durability and maintenance requirements. Additionally, factors such as cost-effectiveness, environmental impact, and regulatory compliance also need to be taken into account during the design process.

- Q: How do geotextiles contribute to groundwater protection?

- Geotextiles contribute to groundwater protection by acting as a barrier between the soil and any potential contaminants. They prevent the infiltration of pollutants into the groundwater by providing a filtration layer that allows water to pass through while trapping harmful substances. Additionally, geotextiles help in stabilizing the soil, reducing erosion and sedimentation that can impact the quality of groundwater.

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles are commonly used in civil engineering and construction projects to create a barrier between different soil types or layers. They help prevent the mixing and migration of soil particles, improving the overall stability and performance of the soil structure.

- Q: Can geotextiles be used in foundation drainage systems?

- Yes, geotextiles can be used in foundation drainage systems. Geotextiles are commonly used as a filter and separator in drainage systems to prevent soil migration and clogging of drainage pipes. They help to improve the efficiency and longevity of foundation drainage systems by allowing water to flow freely while keeping the soil particles in place.

- Q: Principle and Advantages of Permeable Geotextile

- The advantages of permeable geotextile: 1: isolation, the use of polyester staple acupuncture geotextile with different physical properties (particle size, distribution, consistency and density, etc.) of building materials (such as soil and sand, soil and concrete Etc.) to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. 2: filter, when the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand, small Stone, etc., in order to maintain the stability of soil and water engineering. 3: drainage, polyester staple acupuncture geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. 4: reinforced, the use of polyester staple acupuncture geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve the quality of soil. 5: protection, water erosion of the soil, the effective concentration of concentrated diffusion, transmission or decomposition, to prevent soil damage by external forces, the protection of the soil. 6: high tensile strength, good permeability, breathable properties, high temperature, anti-freeze, anti-aging, corrosion-resistant, not moth-eaten.

- Q: Geotextile, 150g how much money per square meter

- 1.2 to 1.5. See quality requirements. Huazhi geotextile material manufacturers

- Q: What are the specifications for geotextiles and geogrids commonly used on expressways?

- You are the production, or sales, or procurement, the question asked, what model is the designer's decision

- Q: Health geotextile how much money ah?

- Health geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. The price according to the weight and standard to set, weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, whitening A, Sinochem, the general national standard, Paul national standard, Wait. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: What are the applications of geotextiles?

- Geotextiles have a wide range of applications in civil engineering and environmental projects. They are commonly used in road construction, where they provide stability, erosion control, and reinforcement. Geotextiles are also utilized in landfills to separate and protect soil layers, preventing contamination. Additionally, they are employed in coastal engineering to mitigate erosion and stabilize shorelines. Geotextiles are also used in drainage systems, agriculture, and landscaping to control erosion, filter water, and promote vegetation growth.

- Q: What are the considerations for geotextile selection in coastal engineering projects?

- There are several important considerations for geotextile selection in coastal engineering projects. Firstly, the geotextile should possess high tensile strength and durability to withstand the harsh coastal environment, including waves, tides, and erosion. It should also have good permeability to allow for proper water drainage while preventing the loss of soil particles. Additionally, the geotextile should be resistant to UV degradation and chemical exposure, as well as be compatible with the surrounding soil and other materials used in the project. Lastly, factors such as installation ease, cost-effectiveness, and the specific requirements of the project should also be taken into account when selecting the appropriate geotextile for coastal engineering projects.

Send your message to us

Geonet High Strength Non Woven Polypropylene Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords