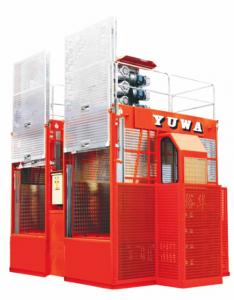

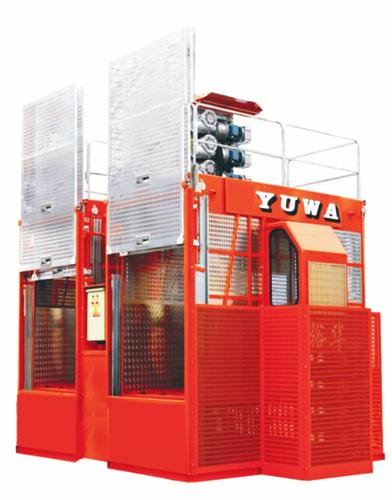

General and Standard Construction Hoist

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Description SC200

Condition: New

Application: Construction

Payload(kg):2*3000

Lifting Speed(m/min):0~33

Motor Power(kw): 2*3*22

Safety Device: 2*SAJ50-1.4

Cage: Single/double cages

Counterweight: No

Certification: CE/ ISO

Place of Origin: China(Mainland)

Model Number: Type:SC300/SC300

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

Feature:

● speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials.construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: : “SC” stands for rack and pinion hoist, ”stands for double cage and capacity

is 2 tons per cage. Q: What is the dimension of the cage?

A: Normally the cage dimension is for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors

- Q: What are the requirements for the construction elevator

- The anti-drop safety device is an important part of the construction elevator, which can be relied on to eliminate the occurrence of the fall accident and guarantee the safety of the crew. So for safety device factory test is very strict, before delivery by the statutory inspection unit for torque measurement, critical speed measurement, measuring the amount of spring compression, each with the test report, after assembly to the construction lifter for drop test under rated load, and the site to use the elevator must be every three months to conduct a drop test. For safety device to the factory for two years for safety device (delivery date), must also be sent to the statutory inspection unit to carry on the test, after testing once a year. So far few inspection, some sites even once every three months to detect don't do drop test, all think that their is no problem for safety device, but once had an accident, repent at leisure. Why not do regular tests and tests? The use of units blindly thinks that not bad is good. Actually good or bad for safety device can only judge by test and inspection in the daily operation is not sure whether it is good or bad, for those who are serving for safety device, or advice for the earlier inspection and regular test, only accomplish know fairly well, to malignant accident prevention rather than cure.

- Q: Is it possible to utilize a building hoist for elevating construction materials?

- <p>Yes, building hoists are commonly used in construction to lift materials. They are designed to transport heavy materials, such as bricks, cement, and steel, vertically between floors. These hoists are crucial for efficient construction, especially in high-rise buildings, as they reduce manual labor and increase safety by minimizing the need for workers to carry heavy loads up ladders or stairs.</p>

- Q: Is it possible to utilize a building hoist for the purpose of lifting large vehicles?

- <p>Yes, a building hoist can be used to lift large vehicles, but it requires a hoist specifically designed and rated for such heavy loads. It's crucial to ensure that the hoist has the necessary capacity and safety features to handle the weight of the vehicle. Additionally, the operation must be conducted by trained professionals following strict safety protocols to prevent accidents. It's also important to check local regulations and guidelines for lifting operations involving heavy machinery or vehicles.</p>

- Q: This question asks for a comparison between electric and pneumatic building hoists, highlighting their distinct features and operational differences.

- <p>Electric building hoists are powered by electricity and are known for their high lifting capacity, speed, and efficiency. They are suitable for heavy-duty applications and can be automated for continuous operation. Pneumatic hoists, on the other hand, use compressed air to generate lifting force. They are quieter, require less maintenance, and are safer in environments where electrical sparks could be hazardous. However, they have lower lifting capacities and are generally slower compared to electric hoists. Pneumatic hoists are also more suitable for applications requiring precise control over the load.</p>

- Q: This question asks if a building hoist can be utilized to lift various types of materials including wood, steel, and concrete.

- <p>Yes, building hoists are designed to lift a variety of materials. They are commonly used in construction to transport materials such as wood, steel, and concrete between different floors. However, it's important to ensure that the hoist is appropriately rated for the weight of the materials being lifted and that safety protocols are followed. Each material may require specific handling techniques or attachments to secure the load properly and prevent damage or accidents.</p>

- Q: The user is asking if it's possible to use a building hoist, typically used for construction, to lift a car.

- <p>Using a building hoist to lift a car is not recommended. Building hoists are designed for lifting materials and equipment in construction settings, not for vehicles. They may not have the appropriate safety features or load-bearing capacity for a car. Attempting to lift a car with a building hoist could result in damage to the car, the hoist, or even personal injury. For lifting a car, it's best to use a vehicle-specific lift or a hydraulic lift designed for such purposes, ensuring safety and proper support.</p>

- Q: This question asks for the method to determine the maximum weight a building hoist can lift.

- <p>The lifting capacity of a building hoist is calculated by considering several factors including the hoist's motor power, the strength of the hoist's construction materials, and the safety factor. The manufacturer usually provides the maximum lifting capacity based on these factors. To calculate it manually, you would need to know the motor's lifting force, the efficiency of the hoist's mechanical system, and apply a safety factor to ensure the hoist operates within safe limits. It's important to follow the manufacturer's guidelines and never exceed the specified lifting capacity to prevent accidents and ensure the hoist's longevity.</p>

- Q: Is it possible to replace an electric control panel with a manual lever in a lifting system?

- <p>While it is theoretically possible to use a manual lever as a substitute for an electric control panel in a lifting system, it is not advisable. Manual levers lack the precision, safety features, and control capabilities of electric control panels. They also cannot provide the same level of feedback or automation. Electric control panels are designed to ensure safe and efficient operation, with features like emergency stop buttons, overload protection, and remote monitoring. Manual levers can pose safety risks and may not meet the operational requirements of modern lifting systems.</p>

- Q: What are the primary materials that are commonly utilized in the construction of hoists?

- <p>Hoists are typically constructed using a combination of metals and synthetic materials for strength and durability. Steel, particularly alloy steel, is a common choice due to its high tensile strength and resistance to wear. Aluminum is also used for its lightweight properties, especially in mobile hoists. Synthetic materials such as nylon or polyester are used for hoist ropes and cables due to their resistance to abrasion and corrosion. Additionally, hoists may incorporate components made from brass, bronze, or other metals for specific parts that require low friction or high resistance to corrosion.</p>

- Q: This question asks about the typical issues encountered with construction hoists and seeks solutions to address these problems.

- <p>Common problems with building hoists include mechanical failures, electrical issues, safety hazards, and improper maintenance. Mechanical failures can be fixed by regular inspection and timely replacement of worn-out parts. Electrical issues are often resolved by checking wiring and connections, and using surge protectors. Safety hazards can be mitigated by ensuring all safety features are operational and by providing proper training to operators. Improper maintenance can be addressed by establishing a routine maintenance schedule and ensuring that all personnel follow safety protocols. Regular inspections, prompt repairs, and operator training are key to maintaining the functionality and safety of building hoists.</p>

Send your message to us

General and Standard Construction Hoist

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords