Gate Valves Made in China with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

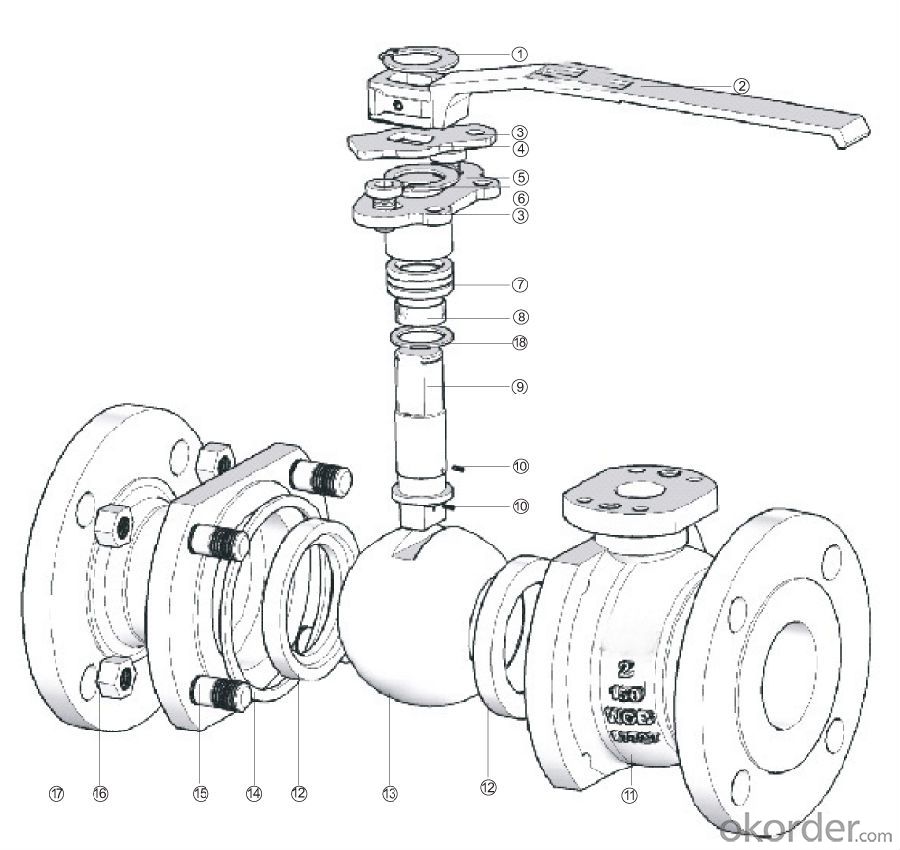

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: The difference between cut-off valve and gate valve

- The working principle is different. The stop valve is an upward stem type, and the handwheel rotates and rises with the stem. Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open, the cut-off valve is not the same. The gate valve has no inlet and outlet direction requirements, and the cut-off valve has the required inlet and outlet!Gate valve and stop valve are shut-off valve, is the most common two valves.From the exterior, the gate valve is shorter than the cut-off valve, especially the bar valve needs a higher height space. Valve sealing surface has a certain degree of self sealing capacity, its spool depends on the media pressure tight contact with the valve seat sealing surface, to achieve tight leakage. Wedge gate valve spool angle is generally 3~6 degrees, when forced to shut down excessive or temperature changes of the valve core is easy to die. Therefore, high temperature and high pressure wedge gate valve, in the structure have taken certain measures to prevent spool stuck. The valve in the opening and closing valve and valve seat sealing surface contact and mutual friction is always so easy to wear sealing surface, especially in close off the valve, the valve before and after the great pressure, sealing surface wear is more serious.

- Q: What is the difference between the model z81x-16q and z81x-16c of the groove gate valve?

- Not 16qIs 16p, the former body is stainless steel, and the latter body is carbon steel

- Q: What is a protective gate valve? What is gate valve knowledge?

- Door gate, refers to the design of anti blocking nuclear explosion shock wave from the pipe into the project inside the valve, composed of a valve body, valve seat, valve plate and wave absorbing device, wave absorbing device leakage hole in the valve body, valve leakage hole is a cylindrical hole, wave valve has two door sealing groove between the cylindrical hole and wave valve double seal ring seal, between the valve body and the flange is double sealing ring seal.

- Q: Why? God, can you explain to me in detail why?

- The exit of the general pump is the first soft connection (shock absorber), followed by the check valve, and then the partition valve (such as butterfly valve, gate valve, cut-off valve, etc.), this is not the final answer.The question is interesting, and no corresponding information has been found in the relevant standards. We have also discussed the related issues, but differences of opinion is relatively large, the advantages of 1, first installed check valve installed after the valve or butterfly valve, check valve, can be protected, especially in a parallel pump, when the pump does not start, another pump starts when the impact force is gate valve or butterfly valve bear, disadvantages: gate valve or check valve who will protect? There have been a case of butterfly valve is broken. 2, first installed gate valve or butterfly valve installed after the check valve, advantages: can protect the butterfly valve or gate valve, the impact on the check valve to bear. Disadvantages: check valve who will protect, check valve by pressure difference switch, if the high pressure high pressure pipe, pump, if the flow is not stable, so check valve will repeatedly switch, will affect the check valve life. Personal opinion: check valve, check valve performance now have changed, many are using the slow closing check valve, so the impact force is two aspects to bear, because exports are not fully open the valve or butterfly valve, so you can put in check after the gate valve or butterfly valve valve. If not the slow closing check valve installed in the valve or the best after the butterfly.

- Q: What is the allowable leakage rate of the gate valve D?

- In GB/T 13927, the leakage rate of the valve is divided into 10 grades, namely: A, AA, B, C, CC, D, E, EE, F, G class. And stipulates that when the order contract does not specify, the metal sealing valve according to D requirements.

- Q: What are the structural differences between parallel and wedge valves?

- The advantages of dual gate plate is sealed and angle precision low temperature is not easy to make the wedge gate, the abrasion of the sealing surface and shim.The disadvantage is that the structure is complex, easy to stick in the dry medium, mainly the upper and lower baffles. After years of corrosion, the gate is easy to fall off. Although the single gate is sealed and angle accuracy requirements are relatively high, difficult processing and temperature change may make the gate wedge and other shortcomings, but has the advantages of simple structure, reliable use, especially to the flexible gate, can produce the micro elastic deformation to compensate for the deviation between the sealing surface angle processing, which is widely used at present.For more information about valves, please keep an eye on the valve knowledge section.

- Q: Internal screw current limiting gate valve (Tan Gang) PN5.0 DN15/ Phi 1 Rc1/2 what does that mean?

- We did thatInternal thread current limiting gate valve (Tan Gang)Body material: carbon steelPressure rating: PN5.0 = 300LB American StandardNominal = DN15 = 1/2"Phi 1 = in the middle of the gate drilling a Phi 1 hole, so that in closing there will be a certain flow, that is, the minimum flow, that is, the current limit.Rc1/2 is thread, which is the connection

- Q: What does gate valve DN80-PN16-QT450 mean?

- The outer diameter of the pipe is usually 89mm;"PN16" means the nominal pressure of the gate valve is 16Mpa;QT450 QT said, nodular cast iron, tensile strength is more than 450MPa 450.

- Q: What gate valve is the J41H-150LBDN100 gate valve?

- Its closing principle is to rely on the valve bar pressure, so that the valve sealing surface and seat sealing surface close together, to prevent the circulation of media. The cut-off valve is divided into three kinds: straight through type, right angle type and direct current type oblique stop valve.

- Q: Is the axial force and torque of the wedge gate valve the same?

- B higher temperature. C nice wedge single gate valve is suitable for high temperature medium easy to coking. Flexible gate valve features: high temperature, a wedge type single gate valve in a special form. Comparison with wedge gate valve.

Send your message to us

Gate Valves Made in China with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches