Gate Valve with Best Price and High Quality from China on Top Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

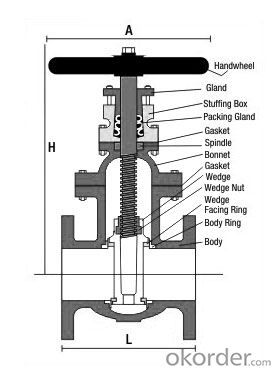

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

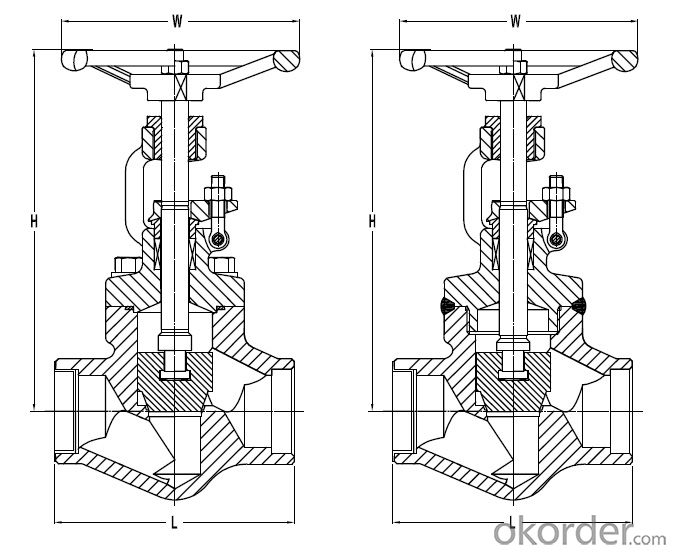

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What is the soft seal gate valve?

- Cautions for installation and maintenance of soft sealing gate valve:For double gate valves, the direction of installation shall be in the vertical position of the valve stem, and the handwheel at the top.The installation of the soft gate valve shall be carried out in strict accordance with the installation environment, installation conditions and installation procedures on the factory manual.After installation, the soft seal gate shall be periodically checked for performance and killed in the cradle before any undesirable conditions occur.

- Q: Z45T-10 what kind of material is the gate valve?

- Cast iron, sealed with copper alloy inside. Shanghai Yu Cheng fluid on the professional production of this thing,

- Q: What does gate z41t-10 150 mean?

- According to JB/T308-2004 "valve type programming method"Z gate valve4 flange connection1 Ming wedge single gateT sealing cover material is copper alloy10 nominal pressure PN10PN16 below no marked valve body code, body material is gray cast iron150 nominal size DN150

- Q: What are the main types of gate valves?

- According to the thread position of the valve stem, can be divided into two kinds of open rod gate valve and dark rod gate valve.

- Q: What's the difference between open rod gate and dark rod gate valve?

- 3, dark rod valve is located inside of the body, in the process of opening and closing, stem only rotation move, the gate in the valve body lifting; the valve stem rod driven gate valve with the valve stem of the lifting drive thread in the external body, according to the direction of movement of the stem and the position of judge the gate opening and closing and position;

- Q: What are the common standards for gate valves?

- 1, product standardsGeneral purpose valves, flanged connections, iron gate valves, GB/T 12232-2005General requirements for steel valves GB/T 12224-2005"Steel flat gate valves for pipelines" JB/T 5298-91Inspection and test of valves. JB/T 9092-1999Standard for safety evaluation of drinking water distribution equipment and protective materials GB/T 17219-1998

- Q: What are the structural differences between parallel and wedge valves?

- The advantages of dual gate plate is sealed and angle precision low temperature is not easy to make the wedge gate, the abrasion of the sealing surface and shim.The disadvantage is that the structure is complex, easy to stick in the dry medium, mainly the upper and lower baffles. After years of corrosion, the gate is easy to fall off. Although the single gate is sealed and angle accuracy requirements are relatively high, difficult processing and temperature change may make the gate wedge and other shortcomings, but has the advantages of simple structure, reliable use, especially to the flexible gate, can produce the micro elastic deformation to compensate for the deviation between the sealing surface angle processing, which is widely used at present.For more information about valves, please keep an eye on the valve knowledge section.

- Q: GB 300 gate valve, a multi?

- GB DN300 flanged gate valve, PN10 manual 245kg bevel gear 315Other pressure levels, please specify specific pressure.Wenzhou Chaoda group Agel Ecommerce Ltd to provide the answer:

- Q: What do gates, Z15T-10, Z15W-16T, Z45T/W-10, Z41T-10 mean?

- 7-, dark bar parallel gate valve, parallel gate valve 9- dark bar;5, sealing materials or lining materials were used R- T- austenitic stainless steel, copper alloy, X- rubber, S- plastic, N- nylon, F- fluorine plastic, H-Cr series stainless steel, hard alloy Y-, J- rubber, M- Monel alloy, Tc- ceramics;6, the body material code Z- K- gray cast iron, malleable cast iron, Q- ductile iron, copper and T- alloy, C- steel, P- chromium nickel stainless steel, R- stainless steel chromium nickel molybdenum, chromium molybdenum vanadium steel V-.For example: for electric, flange connections, Ming Liang wedge double gate, the sealing surface material directly processed by the body, nominal pressure PN0.1MPa body material for gray cast iron gate valve: Z942W-1 electric wedge double gate valve

- Q: What is plug welding gate valve?

- Socket welding valve refers to the use of socket welded connection valve.Simple socket welding is to insert the pipe into the gate joint to weld.The form of socket welding is mainly used for welding small bore valves and pipes, fittings and pipes. Small caliber pipeline wall thickness is thin, and error prone edge ablation, butt welding is difficult, more suitable for socket welding. In addition, the socket of socket welding has reinforcement effect, so it is also used under high pressure. But socketweld also has disadvantages, one is the stress condition is not good after welding, easy welding penetration, pipe inside a gap, so should not be used for piping system of crevice corrosion sensitive medium pipeline system and clean high requirements for socket welding. In addition, ultra high pressure pipeline, even small caliber pipe wall thickness is also very big, can use butt welding connection, as far as possible to avoid socket welding.

Send your message to us

Gate Valve with Best Price and High Quality from China on Top Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches