Galvanized Hot Rolled Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HOT-DIP GALVANIZED PIPE FOR FLUID TRANSPORTATION

1.OD:33.4-114.3mm

2.WT:2.0-9.0mm

3.Zinc:200~600g/m2

Good serveice

We Offer You:

HOT-DIP GALVANIZED PIPE FOR FLUID TRANSPORTATION

HOT-DIP GALVANIZED PIPE FOR FLUID TRANSPORTATION | |||

1. Material | Steel Grade | Q195, Q235, Q345 etc. | |

Material Type | Available in cold rolled and hot rolled | ||

2. Size | W.T | 1.0mm-12mm | |

Diameter | 20mm~273mm | ||

Length | 5.8m-14m | ||

3. Zinc Coating | 200~600g/m2, could be thicker or thinner if you need | ||

4. Certification | BV, IAF, SGS,COC, ISO etc. | ||

5. Welding Technology | Longitudinal ERW | ||

6. Application | Urban construction, machine structure, agriculture equipment, water and gas pipes etc. | ||

7. Packing | Packing in bundle with steel strips; with seaworthy package at the end; could be done with your requirement. | ||

8. Delivery Time | Usually within 10-30 days after receipt of deposit, ASAP | ||

9. Trade Terms | FOB, CFR, CIF etc. | ||

10. Payment Terms | T/T, L/C etc. | ||

11. Loading Port | Xingang , Tianjin | ||

12. Original Place | Tianjin, China | ||

13. Company Information | Name | Reliance Metal Resource Co., Ltd | |

Type | Manufacture and trading company | ||

Supply Ability | 360,000 tons per year | ||

Galvanized Round Steel Pipe's Materials

| Elements Material | Chemical Compsition% | Mechanical Property | ||||||

| C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation (%) | |

| Q195 | 0.06-0.12 | 0.25-0.50 | <0.050 | <0.045 | <0.030 | >195 | 315-430 | 32-33 |

| Q215 | 0.09-0.15 | 0.25-0.55 | <0.05 | <0.045 | <0.030 | >215 | 335-450 | 26-31 |

| Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.030 | >235 | 375-500 | 24-26 |

| Q345 | <0.20 | 1.0-1.6 | <0.040 | <0.040 | <0.55 | >345 | 470-630 | 21-22 |

FAQ of Galvanized Round Steel Pipe

①How is the quality of your products?

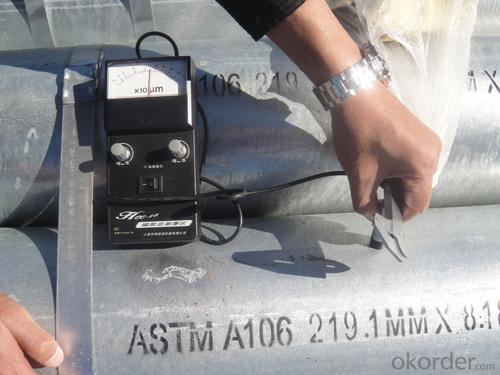

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

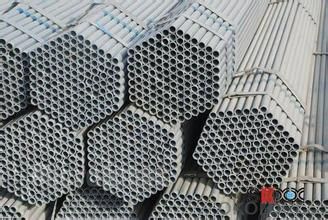

Galvanized Round Steel Pipe Image

- Q: Can steel pipes be used in plumbing systems?

- Yes, steel pipes can be used in plumbing systems. Steel pipes are commonly used for plumbing due to their durability, strength, and resistance to corrosion. They are suitable for both residential and commercial plumbing applications and can effectively transport water, gas, and other fluids.

- Q: How are steel pipes used in the construction of wastewater treatment plants?

- Steel pipes are commonly used in the construction of wastewater treatment plants for various purposes, such as transporting and distributing water, chemicals, and sludge within the facility. They are also used for constructing the main drainage systems, including sewer lines, stormwater drains, and effluent pipes, ensuring efficient and reliable flow of wastewater. Additionally, steel pipes are utilized for constructing the structural framework of treatment units, such as settling tanks, clarifiers, and aeration systems, providing stability and durability to withstand the harsh conditions of wastewater treatment processes.

- Q: Can steel pipes be used for water supply systems?

- Yes, steel pipes can be used for water supply systems. Steel pipes are commonly used in water distribution systems due to their strength, durability, and resistance to corrosion. However, it is important to ensure that the steel pipes are properly coated or lined to prevent rusting and contamination of the water supply. Regular maintenance and inspection are also crucial to ensure the longevity and safety of steel pipes in water supply systems.

- Q: Can steel pipes be used for conveying abrasive materials?

- Yes, steel pipes can be used for conveying abrasive materials. Steel pipes are known for their durability and resistance to wear and tear, making them suitable for transporting abrasive substances such as sand, gravel, or chemicals. Additionally, steel pipes can handle high pressure and temperature conditions, further contributing to their suitability for conveying abrasive materials.

- Q: Can steel pipes be used for underground gas pipelines?

- Yes, steel pipes can be used for underground gas pipelines. Steel pipes are commonly used in the construction of gas pipelines due to their strength, durability, and resistance to corrosion. They provide a reliable and safe means of transporting gas underground.

- Q: What are the factors to consider when selecting pipe materials for corrosive environments?

- To ensure the longevity and effectiveness of a piping system in corrosive environments, several important factors must be considered. Firstly, the corrosion resistance of the pipe material is crucial. It is essential to select a material highly resistant to corrosion as time can cause significant damage to pipes in corrosive environments. Stainless steel, fiberglass, PVC, and CPVC are materials known for their excellent corrosion resistance. Secondly, the chemical compatibility of the pipe material with the corrosive environment should be assessed. Different materials have varying resistance levels to different chemicals, so it is important to ensure that the chosen material can withstand the specific chemicals present. Consulting chemical compatibility charts and seeking expert advice can aid in selecting the right material. Furthermore, the temperature and pressure requirements within the corrosive environment should be taken into account. Some materials have limitations in terms of temperature and pressure resistance, exceeding which can lead to pipe failure. It is crucial to choose a material that can handle the required temperature and pressure ranges without compromising its structural integrity. The cost of the pipe material and its installation should also be considered. While certain materials may offer high corrosion resistance, they may also be more expensive. Striking a balance between the desired level of corrosion resistance and the available budget is essential. Lastly, the maintenance requirements and overall durability of the pipe material should be evaluated. Some materials may require more frequent inspections, cleaning, or repairs compared to others. Considering the anticipated lifespan of the piping system and the ease of maintenance can help in selecting a material that ensures long-term reliability and cost-effectiveness. In conclusion, when selecting pipe materials for corrosive environments, it is important to consider factors such as corrosion resistance, chemical compatibility, temperature and pressure requirements, cost, and maintenance and durability. By carefully evaluating these factors, one can choose a pipe material that best suits the specific corrosive environment and ensures a reliable and long-lasting piping system.

- Q: What are the different standards for steel pipes?

- Steel pipes are subject to various standards that guarantee their quality and compatibility in different applications. Some commonly used standards include: 1. ASTM (American Society for Testing and Materials): In the United States, ASTM standards are extensively used to specify different types of steel pipes, such as seamless and welded pipes. These standards cover dimensions, mechanical properties, and general requirements for steel pipes. 2. API (American Petroleum Institute): API standards are specifically tailored for the oil and gas industry. They provide guidelines for manufacturing, testing, and inspecting steel pipes used in oil and gas exploration, production, and transportation. 3. DIN (Deutsches Institut für Normung): DIN standards are widely adopted in Europe and outline specifications for various steel pipe types, including seamless, welded, and cast iron pipes. These standards cover dimensions, materials, and technical delivery conditions for steel pipes used across industries. 4. BS (British Standards): In the United Kingdom, BS standards are widely utilized for steel pipes in construction, engineering, and other sectors. They provide guidelines for dimensions, materials, and manufacturing processes for steel pipes. 5. JIS (Japanese Industrial Standards): JIS standards are extensively used in Japan and define specifications for different types of steel pipes, including seamless, welded, and cast iron pipes. These standards cover dimensions, materials, and technical delivery conditions for steel pipes used in various industries. 6. ISO (International Organization for Standardization): ISO standards are globally recognized and provide specifications for steel pipes used in diverse industries. They cover dimensions, materials, testing, and quality control requirements for steel pipes. It is crucial to note that specific industries and applications may have unique requirements. Therefore, it is essential to refer to the relevant standard for each specific use case. Complying with these standards ensures the safety, reliability, and compatibility of steel pipes in their respective applications.

- Q: What are the safety precautions to follow when working with steel pipes?

- When working with steel pipes, it is important to follow several safety precautions to prevent accidents and injuries. Some key precautions include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential hazards. It is also crucial to inspect the pipes for any damage or defects before using them and ensure they are properly secured and supported during installation. Additionally, workers should use caution when handling heavy or sharp-edged pipes and use proper lifting techniques to prevent strains or sprains. Following safety protocols, including using the correct tools and equipment, practicing good housekeeping, and staying alert and focused, is essential to minimize risks and maintain a safe working environment.

- Q: Where is a steel pipe casing usually used?

- A straight tube of carbon steel sheathed on pipes and tubes and threading tubes to protect the joints from damage by electric welding. The purpose is to protect the wires and cables.

- Q: What are the different methods of wrapping steel pipes for corrosion protection?

- Corrosion protection for steel pipes can be achieved through various methods, tailored to specific applications and environmental conditions. Some commonly used techniques include: 1. Tape Wrapping: Steel pipes are wrapped with corrosion-resistant tape, like polyethylene or polypropylene tape, to create a barrier between the pipe and corrosive elements. This reduces the risk of direct contact and subsequent corrosion. 2. Inner Wrapping: A protective coating or lining is applied to the inside surface of the steel pipe. This method is commonly employed for pipes transporting fluids or gases, offering an additional layer of protection against internal corrosion. 3. External Coating: A widely utilized technique involves applying a protective coating to the outer surface of the steel pipe. This coating, which can consist of materials like epoxy, polyethylene, or polyurethane, acts as a barrier against corrosive elements, extending the pipe's lifespan. 4. Cathodic Protection: An electrochemical method is utilized to safeguard steel pipes from corrosion. By connecting the steel pipe to a sacrificial anode, such as zinc or magnesium, the anode corrodes instead of the pipe. This diverts corrosive currents away from the pipe, preventing its corrosion. 5. Heat Shrink Sleeve: Heat shrink sleeves are commonly employed for corrosion protection in underground or submerged scenarios. These sleeves, made of heat-activated material, shrink when heated to form a tight seal around the pipe. By preventing direct contact with moisture and corrosive elements, the sleeve effectively acts as a barrier. 6. Fusion Bonded Epoxy (FBE) Coating: FBE coating entails applying a thermosetting powder coating to the steel pipe's surface, which then fuses to create a protective layer. This coating exhibits strong adhesion and corrosion resistance, making it a popular choice for various steel pipe applications. Choosing the appropriate corrosion protection method for steel pipes depends on factors like the environment, specific corrosive elements, intended use, and other requirements. Seeking professional advice and consultation may be necessary to determine the most suitable technique for a particular situation.

Send your message to us

Galvanized Hot Rolled Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords