Fused Spinel Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Fused Spinel

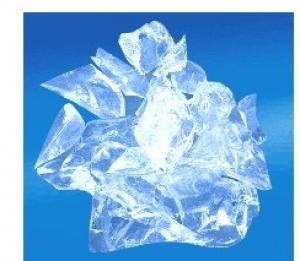

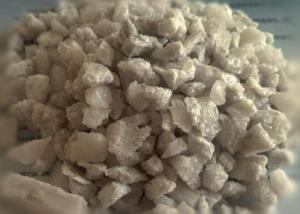

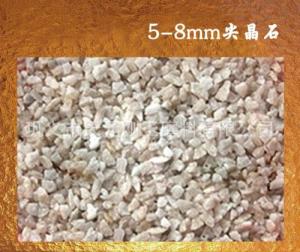

Fused Magnesia-Alumina Spinel is manufactured from high pure raw alumina and magnesia in electric arc furnace, with high bulk density and resistance to thermal shock and chemical corrosion at high temperature.

Specification of Fused Spinel

|

Technical indicators | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Advantages of Fused Spinel:

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: What is unshaped refractory?

- Castable. Castable refractory material factory to provide raw materials and ingredients, field processing, vibrator for compacting, maintenance must be after heat treatment, due to site conditions quality is not stable, but the integrity of the castable in concrete, two aspects of concrete as water and heat castable quality, raw materials the consumption ratio of concrete is 5% ~ 8%.

- Q: Procedures for producing common refractory materials?

- The general procedures of producing refractory materials include calcination of raw materials, selection of raw material , crushing, grinding, screening, mixing, ageing mixture, molding, drying, burning and etc. At present, the refractory factory usually purchases the calcined clinker, so the calcination of raw material is no longer a consideration of common refractory plants.

- Q: What kind of fireproof material is used for steel structure?

- Fireproof material means the coating is with thickness 3 mm (including 3 mm) or less, good decorative effect, capable of expanding foam, fire endurance of generally within 2 h of steel structure fire at high temperatures. fire-resistant coating for steel structure is generally solvent-based systems, with strong bond strength, water resistance, weatherproof, good flowing property, decorative; it slowly expanded at high temperature to a dense layer of fire insulation, which has a strong refractory shock, delaying the rise of steel, protecting steel components. ultra-thin?intumescent?fireproof coatings?for steel?structure can be used by spraying, brushing or rolling, generally using construction steel with fire endurance within 2 h. new type of ultra-thin fireproof coatings for steel structure has a fire endurance of 2 hours or more, mainly using binding agents of polymethacrylate or epoxy resin and amino?resin and chlorinated?paraffin, which are of special structure, added with fire retardant system such as high degrees of polymerization, phosphoric?acid, dipentaerythritol, adding titanium dioxide, wollastonite and other inorganic refractory materials, solvent oil 200 # solvent composite. All kinds of light steel structure, grid and other use of this type of fire-resistant coating conduct fire protection. As such the fire retardant paint coating is ultra-thin, greatly reducing the amount of thin steel structure fire retardant coating, thereby decreasing the total cost of the project. The steel is protected and the fire is prevented.

- Q: How to use fireclay?

- Mix refractory cement (ie aluminate cement CA50) with some refractory aggregate (bauxite, slag from flint clay) and powder (ie, crushed aggregate). Add some water to the mixture and stir, and it can be used. The clinker can be refractory powder.

- Q: Who knows the classifications of magnesia refractory?

- They can be devided into two major categories of fettling magnesite grain and magnesite products. They can be divided into fettling magnesite grain, magnesia?brick, magnesia-silica brick, magnesia-alumina brick, magnesium-calcium brick, magnesia-carbon brick and other varieties according to the chemical compositions and purposes Its performance is greatly affected by CaO / SiO2 ratio and impurities. The load softening point and thermal shock resistance of high purity magnesia brick are much higher than those of the general magnesia bricks. It has high refractoriness and good resistance for alkaline slag and iron slag, which is an important kind of advanced refractory material. Magnesia products are mainly produced by sintering, and sintering temperature is generally between 1500 ~ 1800 ℃. Besides, chemical binder can be added to make unburned?bricks and unshaped refractories. Mainly used in open hearth furnace, electric furnace, oxidation converter, non-ferrous metal metallurgy furnace, cement kiln and calcining kiln for basic refractory.

- Q: who knows the uses of refratories?

- Physical properties of refractories include structural properties, thermal properties, mechanical properties, usability and operation. structural properties of refractories include porosity, bulk density, water absorption, air permeability, pore size distribution. Refractory thermal properties include thermal conductivity, thermal expansion coefficiency, specific heat, heat capacity, thermal diffusivity, thermal emissivity. Mechanical properties of refractories include compression strength, tensile strength, anti bending strength, torsional strength, shear strength, impact strength, abrasion resistance, creep property, adhesive strength, modulus of elasticity. Refractories are used in various fields of steel, nonferrous metals, glass, cement, ceramics, petrochemical, machinery, boilers, light industry, power, military and other fields of national economy. They are essential materials that ensures the production run and technological development of the above industries, and play an important role in promoting the developemnt of high temperature industrial production. the usability of refractories include refractoriness, softening temperature under a fixed load, linear?change?on?reheating,thermal shock resistant performance,slag resistance, acid resistance, alkali resistance, hydration resistance, carbon monoxide resistance, conductivity, oxidation resistance.

- Q: How to make fire resistant materials for building stoves

- Legend of the old version has been upgraded, or can not enter the server, is not legend stopped?

- Q: whether the aluminum silicate thermal insulation material is fireproof or not?

- Yes, it is fireproof. Refractory thermal insulation material mainly refers to the inorganic thermal insulation materials and composite thermal insulation materials. According to the shape it can be divided into: Fibrous finishing, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber,ect.. it takes the flint clay clinker as raw material, produced by the fusion of resistance or electric arc furnace and the injection of fiber forming. characteristic: Low thermal conductivity, excellent thermal and chemical stability, without binder and corrosive material.

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory includes metallurgical auxiliary materials.

- Q: What refractory materials are used in power plant

- And then I will introduce some application of thermal material in power plant (below) I hope I can help you. Energy saving is the trend of future industrial development efforts, grinding machine, conveyor belt, so the production of light thermal insulation materials will gain state support, drying kiln. Our factory mainly produce light thermal insulation brick. The refractory material we use most is light insulation brick, and the equipment used is sand mixer (Luohe, Henan)

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fused Spinel Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords