Fused Silica Sand - Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION | |

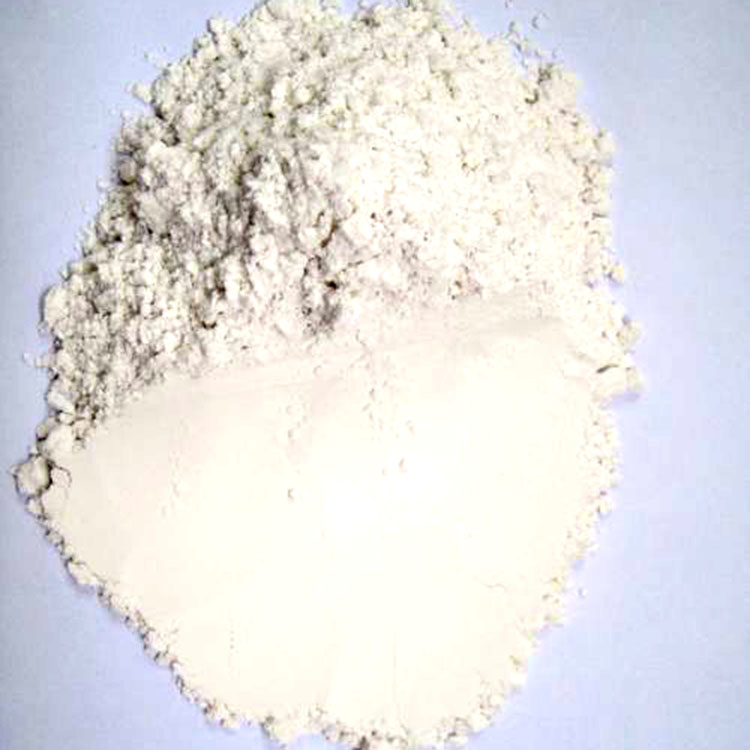

Item | Fused Silica Powder |

Size | D50=9~11um |

Application | Epoxy insulation encapsulant material / Epoxy Molding Compound (EMC), Copper Clad Laminate (CCL), Electromagnetism Industry, Electronic Industry, Ceramic Industry, The Aerospace Industry, Glass Industry, Plastics Industry, Grinding Material Industry, Coating Industry, Investment Casting Industry, Thermal Insulation Product of Calcium Silicate, Refractory Material |

Model No. | R610 |

MOQ | 5 ton |

Material | natural silica rock after melting |

H.S. CODE | 25061000 |

PRODUCT CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES | |

SiO2 | >99.99% |

Al2O3 | <0.015% 1000ppm |

Fe2O3 | <0.002% 50ppm |

Density | 2.2 |

Whiteness | >92% |

Moisture content | <0.05% |

Mohs hardness | 6.5 |

Igniting loss | <0.12% |

Appearance | powder |

- Q: Who knows what is the standard of insulation material whose fire proof is level A?

- Non combustible materials of level A: WW inorganic active wall thermal insulation material, Cement foaming thermal insulation board, Glazed hollow bead insulation mortar, rock wool board, Glass wool board, Foam ceramic.Non combustible materials of level A, endowed with low density, low thermal conductivity, higher bearing capacity, convenient construction , economy and durability, are widely used in heat pipe, heat equipment, other industrial pipeline equipment , thermal insulating materials on industrial buildings, and used as heat preservation, thermal insulation, sound absorption materials of industrial and civic buildings.Non combustible materials of level A are used more for refractory protection coating material of steel structure because of its good thermal stability.

- Q: Do you know the refractories?

- The so-called main component refers to the first phase and the second phase component, and the content accounts for about 90% of the total chemical composition. The development of modern technology more and more number of refractory material ingredients, so the second phase, the third phase component, adjusting the second phase, the third phase composition can generate a new technology in the chemical composition of the first phase beyond the limitations of the classification, a classification method is the most commonly used.

- Q: What are the characteristics of thealuminium oxide refractory?

- Alumina refractory are characterized by uniform granularity, mobility, good dispersity. And it has good acid and alkaline slag erosion resistance, high strength, abrasion resistance, high melting point, erosion resistance , anti-flush and excellent thermal shock resistance.

- Q: Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on. The judgment condition of the fire resistance There are three conditions for components' fire resistance limit to be reached, namely, the fire resistance limit of the building component: Loss of support and integrity; loss of time to fire the role of the time; as long as any of these three conditions is met, it will reach its limit of fire. Hope my answer will help you.

- Q: Would you like to know if there are any enterprises in Mianyang that need fire-resistant materials?

- Big business needs to be usedIntroduce several big: Jiuzhou 208827 and Changhong

- Q: Who can tell somthing about how to choose fire resistant rating of fire resistance rolling shutter doors?

- There is no necessary connection between them. Different fire resistant ratings of bulidings require different fire endurance of different elemements of buildings. According to the fire endurance, fireproof doors can be divided into A-grade, B-grade and C-grade, whose fire endurance should not be less 1.2h, 0.9h and 0.6h respectively. A-grade fireproof doors can be even applied to the material whose fire resistant rating is at secondary level. "Building Regulations" mention that fire resisting shutter can be used as partition of fire?compartment in those places where setting firewalls is not so easy. When using fire resisting shutter whose fire endurance doesn't include unexposed surface temperature rise, it should install closed independent automatic sprinkler system for protection on both sides, and the sprinkler sholud last at least 3 hours.

- Q: How to choose the material of refractory?

- Long using temperature of aluminum oxide fiber is 1400 ℃, containing chromium aluminum silicate fiber, quartz, high purity aluminum silicate fiber, long-term use of temperature is 1000-1200 ℃ has aluminum silicate refractory fiber according to different raw materials, advanced refractory fiber (such as alumina. Commonly used vitreous aluminum silicate refractory fibre is amorphous, zirconium oxide refractory fibre) using temperature is 1700 ℃ view as >and the best temperature is 1300 ℃. Crystalline refractory fiber are polycrystalline mullite fiber, including ordinary aluminum silicate fiber, alumina and graphite refractory fiber, etc. The use of common refractory fiber temperature is 1150 ℃;>

- Q: What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

- Q: How many levels are there in the classification of PP fireproof materials?

- The level of fireproof materials: A-level: Non-combustible building materials have rare chance to burn. A1-level: Non-combustible materials, no open fire A2-level: Non-combustible materials, smoke should be tested and qualified. B1-level: Fire-retardant building materials: Fire-retardant materials are good at resisting flame. It is difficult for them to burst into fire when coming across open fire in the air or at high temperature. It will not quickly get wilder and when the fire source removes, it will be extinguished immediately. B2-level: Combustible building materials: Combustible building materials can play a certain role in preventing combustion. It will immediately burst into flames when coming across open fire or at high temperature, and will lead to fire spreading, such as wooden pillars, roof frames and beams as well as stairs. B3-level: Inflammable building materials are highly flammable with no flame retardant ability, fire risk is high.

Send your message to us

Fused Silica Sand - Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords