Rock Wool Furnace Cement Kilns Pizza Oven High Refractoriness Brick for Cement Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Block | Material: | Castable |

| SiO2 Content (%): | 0.5-15 | Al2O3 Content (%): | 55-95 | MgO Content (%): | 0.3 |

| CaO Content (%): | 0.5 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 3-5 |

| Model Number: | HD-CH1 HD-CH2 HD-CH3 | Brand Name: | HD | Furnace Blocks: | Furnace Blocks |

Packaging & Delivery

| Packaging Details: | Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips. |

| Delivery Detail: | Within 15 days |

CLIENTS:

1 KROEA C.SOL

2 Vietnam hefa

3 Indian SAIL ( BSP )

4 Indian MSPL ( Bellary )

5 Indian Maruti Ispat steel company

6 Indian JEEVAKA steel company

7 Indian X-INDIAN

8 NMDC

9 Indian JSW

10 Indian JANKI CORP LIMITED

11 Russia R.L

12 K.S.A LION STEEL GROUP

13 Indian ta ta

14 masteel malaysia

15 annjoo steel malaysia

16 PT INDO

17 M METAL THAILAND

------------------- etc

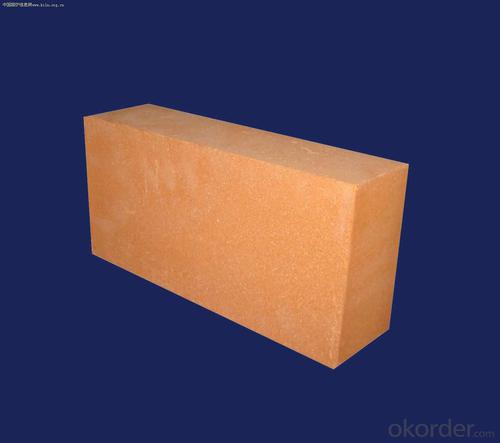

Refractory Bricks for Heating Furnace

The abrasion resistance blocks feature high density, good resistance to slag corrosion and high temperature strength. These blocks are used for launder, platform, sliding rail of reheating furnace, with service life of 1-2 years. The non-slag castable is used as heating furnace bottom and plate, with good abrasion resistance and no slag adhesion.

TYPE | HD-CH1 | HD-CH2 | HD-CH3 (non-slag castable) | |

Chem. Cop (%) | Al2O3+Cr2 O3 | ≥90 | — | ≥90 |

Al2O3+Zr O2 | — | 93 | — | |

Bulk density (g/cm3) | 110°C × 24h | ≥3.2 | ≥3.3 | ≥3.0 |

MOR (MPa) | 110°C × 24 h | ≥10 | ≥10 | ≥10 |

1500°C × 3 h | ≥12 | ≥12 | ≥12 | |

C.S (MPa) | 110°C × 24 h | ≥40 | ≥40 | ≥30 |

1500°C × 3 h | ≥100 | ≥100 | ≥80 | |

L.C (%) | 110°C × 24 h | ≤±0.1 | ≤±0.1 | ≤±0.1 |

1500°C × 3 h | +0.3~-0.5 | +0.3~-0.5 | +0.3~-0.5 | |

- Q: What does the rock wool board look like?

- What does the rock wool board look like?

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- What are the main categories of rock wool products in interior decoration materials?

- Q: How to judge the quality of rock wool

- Rock wool products, the important content of rock wool products, the density range is kg / m3 100-250 ± 15%, in this density of rock wool board to meet product quality requirements

- Q: The difference between rock wool and rock wool

- Yanmian tube is a kind of rock wool insulation material mainly used in the pipeline. After the natural basalt is melted by high temperature, the artificial inorganic fiber is made from the high speed centrifugal equipment, and the special binder and dustproof oil are added. Temperature curing, made into a variety of specifications, different requirements of the rock wool insulation tube

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- Rock wool insulation material fire rating is how much

- Q: Rock wool board is inorganic composite insulation material

- Rock wool composite insulation material depends on what you compound the material

Send your message to us

Rock Wool Furnace Cement Kilns Pizza Oven High Refractoriness Brick for Cement Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords