Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

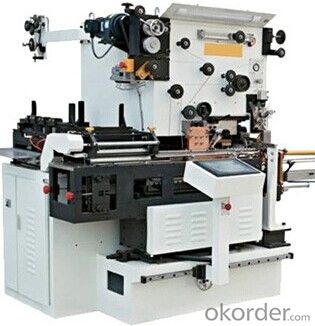

Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine Usage and Applications

Type:Packaging Line

Condition:New

Application:Chemical, Machinery & Hardware

Packaging Type:Cans

Packaging Material:Metal

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V

Power:40KW

Place of Origin:Zhejiang, China (Mainland)

Certification:CE

After-sales Service Provided:Engineers available to service machinery overseas

Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine Main TechnicalParameters

1.Fully Automatic System

2.VVVF Device

3.High Speed

4.Fault Self-analysis

Name | Automatic Tin Can Seam Welding Machine |

Model | FH18-65ZD |

Usage | It's used for tin can body automatic seam welding |

Production Capacity | 40-100 cans/min |

Welding Speed | 6-26m/min |

Overlap | 0.4mm 0.6mm |

Cooper Wire | Ø1.38 Ø1.5mm |

| Suitable Can Diameter | Ø65-180mm |

| Suitable Can Height | H60-280 |

| Suitable Tinplate Thickness | 0.2-0.35mm |

| Compressed Air Consumption | 600L/min |

| Compressed Air Pressure | 0.5-0.7Mpa |

| Cooling Water | ≤20°C, 0.4-0.5Mpa, 10L/min |

| Power | 380V, 50Hz, 40KW |

| Dimension | 1750*1100*1800mm |

| Weight | 1800KG |

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you have your own website here, through the optimization and promotion, to promote their products out, the customer concern, love content search, when people search through GG to see your home site, you may consult. There are many ways

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resinUre-aformaldehyde resinsUrea formaldehyde polymer. Also called urea formaldehyde resin. The cross-linking English abbreviation UF. molding, the product is insoluble and infusible thermosetting resin, urea formaldehyde resin cured phenolic resin than the color of light, translucent resistance, weak acid and weak alkali, good insulation properties, excellent wear resistance, low price but, in case of strong acid and strong alkali decomposition, weather resistance is poor. The name Beetle. urea and 37% formaldehyde aqueous solution can be obtained by the polycondensation of linear urea formaldehyde oligomer in catalytic acid or alkali industry, with alkali as catalyst, reaction temperature of about 95, the molar ratio of formaldehyde to urea as 1.2.0, to ensure that the resin curing reaction. The first step to generate and dimethylol urea, then hydroxymethyl amino and soluble resin by further condensation, if by acid catalysis, easy to cause the product to be stored to gel. In neutral condition. The linear UF resin for ammonium chloride Curing agent can be cured at room temperature. The molding powder at 130 to 160 DEG C heat curing accelerators such as zinc sulfate, trimethyl phosphate, two oxalic acid ethyl ester can accelerate the curing process. The urea formaldehyde resin is mainly used in the manufacture of molded plastic manufacturing, daily life products and appliance parts, also can be used as adhesive, paper and fabric sheet the pulp, plywood, decorative board and so on. Because of its light color and easy coloring, products often colorful and magnificent.

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

- Q: Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

Send your message to us

Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords