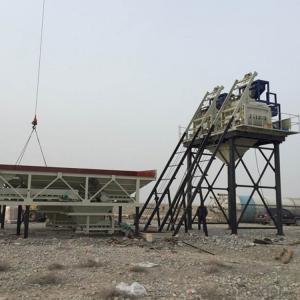

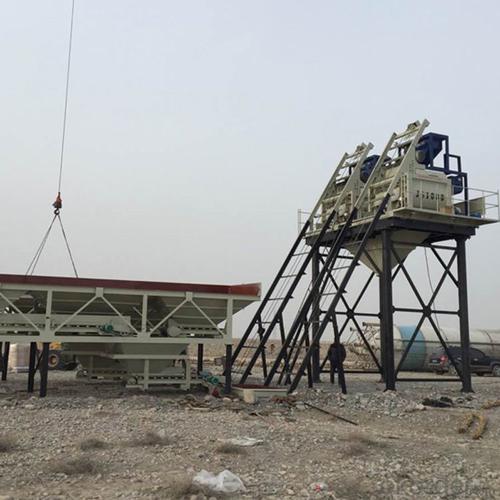

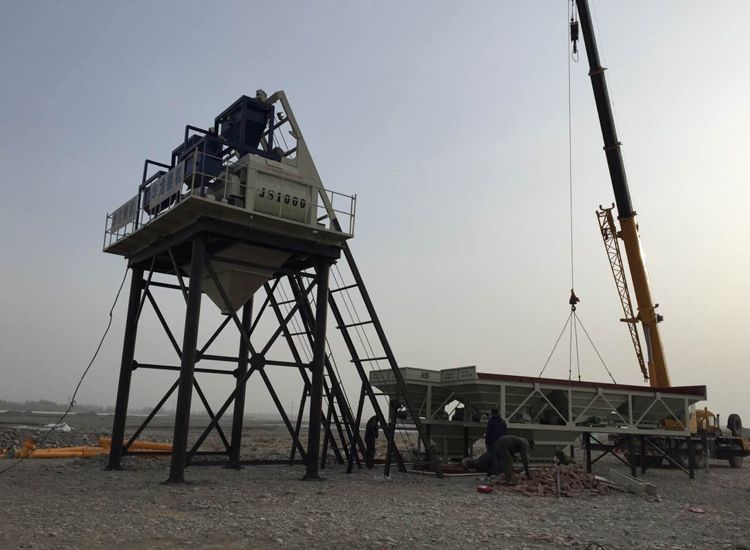

Full automatic concrete quantitative filling weighing system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 300 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

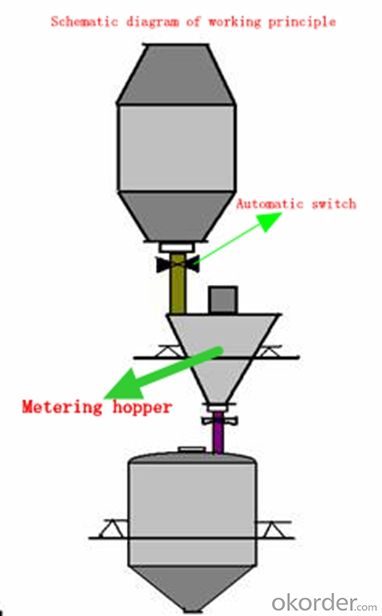

Working principle:

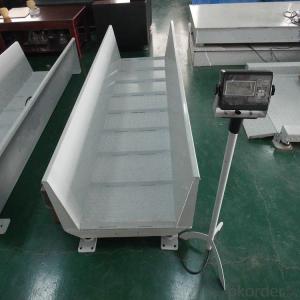

The middle conical bucket is a metering bucket. When the metering bucket is zero, the output circuit of the control instrument is closed, and the upper bin switch is opened to start feeding. When the weight of the material in the measuring hopper reaches the set value, the output signal of the instrument is controlled to close the hopper and the stirring motor starts to stir. The stirrer of the metering bucket stops working when the set stirring time is reached, and the lower mouth of the metering bucket opens, and the stirred material enters the lower bin. When the weight of the metering hopper is zero, the process starts again.

The material level of the lower warehouse has a weight signal showing the remaining% of the cabin. And set the minimum line. When the bunker reaches the lowest line, the metering hopper can start working feed.

This manual is for reference by the operators and installers of

XK3190-C602 indicator during their operation or installation and testing.

Chapter 1 and chapter 2 of this manual introduce the technological features and

parameters of the indicator in a general manner. Chapter 3 and chapter 4

describe the installation, parameter setting and calibration methods which can

be referred to by installers and repairmen as well as by on-site operators who

need to adjust the working modes and parameters of the indicator. Chapter 5

gives out the details of on-site operation methods when the indicator is used to

control quantitative scale. Chapter 6 explains the ways and working procedures

of the indicator when it is used to control quantitative scale, which can assist

installers and operators in understanding the setting of each parameter. Chapter

7 covers the on-site operation methods of indicator when it is used to control

Batching scale. Chapter 8 focuses on the ways and working procedures of the

indicator when it is used to control Batching scale, which can help installers

and operators understand the setting of each parameter. The annexes provide

information for error prompt message, communication format, and general

problems.

Send your message to us

Full automatic concrete quantitative filling weighing system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 300 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches