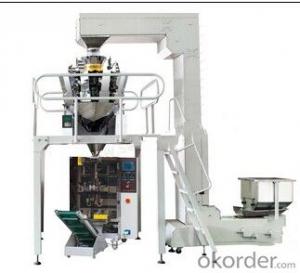

Combined Weighing Full Automatic Packing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

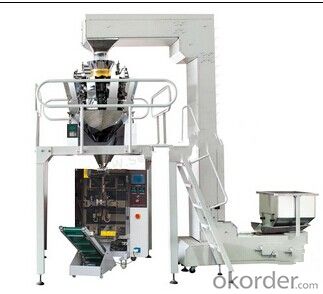

Combined Weighing Full Automatic Packaging Machine System (SK-200DT,SK-220DT)

Model | SK-200DT | SK-220DT |

Air Consumption | 0.65Mpa,2.5M3/min,6kg/cm2 | 0.65Mpa,3M3/min,6kg/cm2 |

Metering Device | 10 Head Combined Weigher | |

Metering Accuracy | ±0.3-1.5g | |

Material Elevator Speed | Max 90 buckets/min | |

Vibrator Speed | Adjustable | |

Take Away Speed | Max 60 bags/min | |

Packing Film Width | 120-380mm | 180-420mm |

Bag Length | 80-240mm | 80-300mm |

Bag Width | 50-180mm | 80-200mm |

Packing Film Roll Diameter | Max.360mm | |

Packing Speed | 5-70bags/min | |

Packing Film Thickness | 0.04-0.08mm | |

Power of SK-200/220 | 220V,50/60Hz,2.4Kw | |

Power of Z type Elevator | 380V,50Hz,750W | |

Power of SK-130 | 220V,50/60Hz,40W | |

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width,bag length

3. Bag shape

4. Packing film material

5. Machine frame

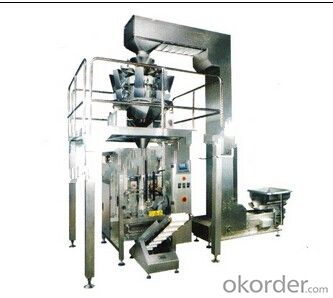

Combined Weighing Vertical Packaging Machine (SK-520DT,SK-620DT,SK-720DT)

Model | SK-520DT | SK-620DT | SK-720DT |

Air Consumption | 0.65Mpa,3M3/min,6kg/cm2 | ||

Metering Device | Ten head combined weigher | ||

Metering Accuracy | ±1% | ||

Material Elevator Speed | Max 90 buckets/min | ||

Vibrator Speed | Adjustable | ||

Take Away Speed | Max 60 bags/min | ||

Packing Film Width | Max 520mm | Max 620mm | Max 720mm |

Bag Length | 80-350mm | 100-400mm | 180-450mm |

Bag Width | 100-250mm | 150-300mm | 180-350mm |

Packing Film Roll Diameter | Max.360mm | ||

Packing Speed | 5-50bags/min | ||

Packing Film Thickness | 0.04-0.08mm | ||

Power of SK-520/620/720 | 220V,50/60Hz,3Kw | ||

Power of Screw Elevator | 380V,50Hz,750W | ||

Power of SK-130 | 220V,50/60Hz,40W | ||

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width & bag length

3. Bag shape

4. Packing film material

5. Machine frame

Combined Weighing Full Automatic Packing System (SK-420DT)

Model | SK-420DT |

Air Consumption | 0.65Mpa,3M3/min,6kg/cm2 |

Metering Device | 10 Head Combined Weigher |

Metering Accuracy | ±0.3-1.5g |

Material Elevator Speed | Max 90 buckets/min |

Vibrator Speed | Adjustable |

Take Away Speed | Max 60 bags/min |

Packing Film Width | 180-420mm |

Bag Length | 80-300mm |

Bag Width | 80-200mm |

Packing Film Roll Diameter | Max.360mm |

Packing Speed | 5-70bags/min |

Packing Film Thickness | 0.04-0.08mm |

Power of SK-200/220 | 220V,50/60Hz,2.4Kw |

Power of Z type Elevator | 380V,50Hz,750W |

Power of SK-130 | 220V,50/60Hz,40W |

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width,bag length

3. Bag shape

4. Packing film material

5. Machine frame

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (1) calculate the average of two samples;(2) the variance of two samples was calculated;(3) which packaging machine is more stable in packing quality?(1) according to the average, the number divided by the sum of each group;

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resinUre-aformaldehyde resinsUrea formaldehyde polymer. Also called urea formaldehyde resin. The cross-linking English abbreviation UF. molding, the product is insoluble and infusible thermosetting resin, urea formaldehyde resin cured phenolic resin than the color of light, translucent resistance, weak acid and weak alkali, good insulation properties, excellent wear resistance, low price but, in case of strong acid and strong alkali decomposition, weather resistance is poor. The name Beetle. urea and 37% formaldehyde aqueous solution can be obtained by the polycondensation of linear urea formaldehyde oligomer in catalytic acid or alkali industry, with alkali as catalyst, reaction temperature of about 95, the molar ratio of formaldehyde to urea as 1.2.0, to ensure that the resin curing reaction. The first step to generate and dimethylol urea, then hydroxymethyl amino and soluble resin by further condensation, if by acid catalysis, easy to cause the product to be stored to gel. In neutral condition. The linear UF resin for ammonium chloride Curing agent can be cured at room temperature. The molding powder at 130 to 160 DEG C heat curing accelerators such as zinc sulfate, trimethyl phosphate, two oxalic acid ethyl ester can accelerate the curing process. The urea formaldehyde resin is mainly used in the manufacture of molded plastic manufacturing, daily life products and appliance parts, also can be used as adhesive, paper and fabric sheet the pulp, plywood, decorative board and so on. Because of its light color and easy coloring, products often colorful and magnificent.

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

Send your message to us

Combined Weighing Full Automatic Packing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords