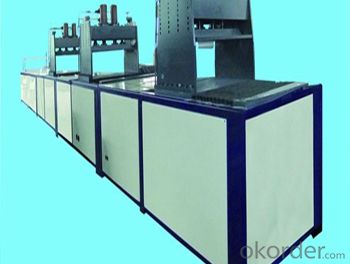

FRP pultrusion machine and strengthen profile making equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP pultrusion machine and strengthen profile making equipment

Product Description:

We manufacturer kinds of FRP filament winding machines for different usage, the following include:

1.FRP drain pipe/marine pipe production line

2.FRP tube continuous production line

3.FRP storage tank production line

4.FRP cable protection production line

5.FRP heat insulating tube production line

6.FRP oil pipe/high pressure/low pressure pipe production line

7.FRP vertical tank production line

Product Features:

1.The main machine is steel structure, stainless steel panel, side panel is paint. With the two kinds of pultrusion modes:Debugging and succession, it is convenience to adjust the production craft;

2.Traction gantry makes ordered according to requested length.

3.The machine had two hydraulic pressure system, it had strong ability of anti-interference;

4.Using function: it have single and double manually operated gantry and double gantry automatic reciprocating running function. Automatic intermittent time can be automatically settled, and the actual production tension can be feedback by sensor.

Product Parameter:

Name | FRP pultrusion machine and strengthen profile making equipment |

Brand | CMAX |

Weight | 3-15T |

Dimension(L*W*H) | 4100mm*1550mm*1460mm |

Power | 90KW |

Voltage | 380V 50HZ 3Phase(Customized) |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Customizable |

Warranty | 1Year |

Time of Delivery | 30-45 days |

Product Show:

- Q: this month bought a 180 thousand of the equipment and issued a value-added tax invoices, this sum of money can be deducted? How much deduction?Previously fixed assets are not deductible? Is this a policy that has just been changed this year? What's the tax rate? Thank you!

- Can be deducted from the value-added tax invoices on value-added tax deductible, in addition to the purchase of equipment costs, if there are qualified transport documents, you can also by freight * 7% deduction of input tax

- Q: How does a lathe process a plastic flowerpot mold?

- Now generally do not lathe processing, and are processed with CNC

- Q: I do not know the classification details and processing procedures, as well as the purchase of such equipment, the need for experienced master guidance, you can also join the cooperation,

- Different kinds of waste plastics have different characteristics. As far as impurity content is concerned, waste materials in the middle and outer corners of the factory produce impuritiesThe content of less than 0.1%, piled up scrap for a period of time and other products used for% impurity content 0.1 ~0.5%, mixed with aluminum, cloth and paper composite plastic waste impurities are often more than 10%. For used waste plastics,According to different use conditions, will include ultraviolet radiation, heat, oxygen aging effect, pollutants.Ring. For different shapes of waste plastics, the volume density of materials after crushing is very different, film, sheet, flatThe volume density of the crushing material is smaller, which is a problem that must be considered in the process of waste plastics recycling and granulation.Two. Pretreatment of waste plasticsFrom discarded packages, such as bags, shopping bags, bottles, cans, boxes and waste agricultural film waste plastics, inPretreatment prior to granulation. The pretreatment process mainly includes classification, cleaning, crushing and drying.Classification work is the classification of miscellaneous waste plastics products according to the type of raw materials and product shapes classification. By raw materialsClass sorting requires operators to have a good knowledge of identifying plastic varieties, and the purpose of sorting is to avoid different speciesThe resulting polymers are incompatible with recycled materials and have poor performance. They are classified according to the shape of the product to facilitate the use of waste plasticsThe crushing process can be carried out smoothly, because the film, flat and fabric used in crushing equipment with some thick and hard wareThe crushing equipment often can not replace each other.

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- The market has been the emergence of more environmentally friendly alternatives such as polypropylene foam, honeycomb paperboard and pulp molding products, recycling mechanism should be set up this kind of packaging materials, such as increasing the recovery of kinds of cushioning packaging materials in the recycling, the environmental protection material to be vigorously promoted.Because of its inability to degrade naturally, plastics have caused many animal tragedies. For example, the monkeys in the zoo, pelicans, dolphins and other animal, are readily lost visitors swallowed 1 plastic bottles, and finally as indigestion and painful death; looked beautiful and pure sea, approaching the look, in fact, filled with various kinds of unable to accommodate the oceans of plastic waste, in more than one the dead birds sample intestines, that cannot be digested all kinds of plastic.The most dangerous of plastic products is phthalate two, a substance that causes the decline in sperm counts in men. The EU has already banned cosmetics, teething rings and chew toys for children using a variety of phthalate two formate. Still, pregnant women are exposed to phthalates, which are often used to soften household items, such as plastic furniture, shoes, PVC floors, and plastic for shower curtains, two.

- Q: Which kind of engineering plastics has good processability?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: Which kind of engineering plastics has good processability?It requires small deformation and high machining accuracy when subjected to force

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: How are the plastic products made of this texture processed?

- jointThe method of joining a plastic part is welding and bonding. Welding is the use of hot welding electrode welding, hot welding using hot welding, and high-frequency welding, friction welding, induction welding, ultrasonic welding, etc.. Bonding method can be divided into flux, resin solution and hot melt adhesive according to the adhesive used.Surface modificationThe purpose is to beautify the surface of plastic products, usually including: mechanical modification, namely with filing, grinding and polishing process, the removal of parts on edges, burrs, and fixed size; finishing, including coating surface parts, the use of a solvent to surface brightening, covered with patterned thin film surface; colour. Including painting, printing and printing; metal plating, including vacuum coating, electroplating and chemical plating method etc.. Among them, the hot stamping is heated, under pressure, the hot film on the color of aluminum foil (or other pattern film) transferred to the workpiece. Many household appliances and building products, articles and so on use this method to obtain the metal luster or the wood grain and so on the pattern.assemblingThe operation of assembling plastic parts into complete products by means of bonding, welding and mechanical joining. For example: plastic profiles, through sawing, cutting, welding, drilling and other steps, assembled into plastic window frames and plastic doors.

- Q: I don't know how much money it needs! Raw materials are used plastic baskets!

- Production of this material, a basic set of machinery and equipment investment of about 70 thousand, if the amount of large, you can choose to configure the machine at around 200 thousand.

- Q: Plastic processing process

- The purpose is to beautify the surface of plastic products, usually including: mechanical modification, namely with filing, grinding and polishing process, the removal of parts on edges, burrs, and fixed size; finishing, including coating surface parts, the use of a solvent to surface brightening, covered with patterned thin film surface; colour. Including painting, printing and printing; metal plating, including vacuum coating, electroplating and chemical plating method etc.. Among them, the hot stamping is heated, under pressure, the hot film on the color of aluminum foil (or other pattern film) transferred to the workpiece. Many household appliances and building products, daily necessities and so on use this method to obtain the metal luster or the wood grain and so on the pattern.

Send your message to us

FRP pultrusion machine and strengthen profile making equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches