FRP Pultrusion Profiles Fiberglass Grid for Stairs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

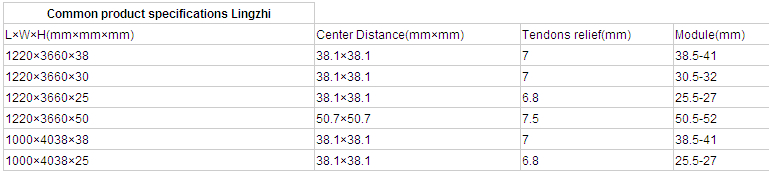

Specifications

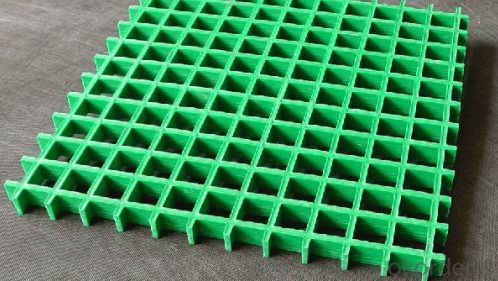

fiberglass mesh grating

1.meet ASTM E-84 AND ISO9001

2.anti-corrosion floor

3.anti-conductive

4.walkway,platform,trench cove

fiberglass mesh grating

Corrosion and Chemical resistant;Slip-resistant ;High strength-to-weight ratio;Ergonomic ;Low maintenance ;Fire retardant ;Easily fabricated and installed

Panel Size:

- Q: Are FRP pultrusion profiles resistant to hydrocarbons?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to hydrocarbons. The combination of various reinforcing fibers such as fiberglass or carbon fiber with a polymer matrix makes FRP materials highly resistant to chemical corrosion, including hydrocarbons. This resistance makes FRP pultrusion profiles a suitable choice for applications where exposure to hydrocarbons is expected, such as in oil and gas industry, chemical processing plants, or fuel storage facilities. However, it is important to note that the level of resistance can vary depending on the specific type of resin used in the FRP material and the concentration and temperature of the hydrocarbons involved. Therefore, it is recommended to consult with the manufacturer or supplier of the FRP pultrusion profiles to ensure their compatibility with the specific hydrocarbon environment in question.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- Yes, FRP pultrusion profiles can be used in the construction of offshore platforms. FRP, or fiber-reinforced polymer, offers excellent corrosion resistance, high strength-to-weight ratio, and durability, making it suitable for the harsh marine environment. These profiles can be customized to meet the specific requirements of offshore platforms, providing structural support and stability while minimizing maintenance needs.

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Yes, FRP pultrusion profiles can be used in the automotive industry. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These profiles can be used for various automotive applications including body panels, structural components, and interior parts.

- Q: Are FRP pultrusion profiles resistant to alkalis?

- Yes, FRP pultrusion profiles are generally resistant to alkalis.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent resistance to corrosion, high strength-to-weight ratio, and dimensional stability, making them ideal for use in chemical reactors. Additionally, FRP materials can withstand a wide range of chemical environments and temperatures, making them a reliable choice for this application.

- Q: Are FRP pultrusion profiles resistant to fading or discoloration?

- FRP pultrusion profiles possess exceptional resistance against fading and discoloration. This attribute stems from the inherent properties of the materials employed in their construction. Typically, FRP profiles are fabricated using a blend of fiberglass reinforcements and a polymer resin matrix, both of which inherently resist UV radiation and other environmental factors that lead to fading and discoloration. The polymer resin matrix used in FRP profiles is specifically designed to exhibit outstanding chemical resistance and UV stability. As a result, the profiles retain their original color and appearance for an extended duration. This makes FRP pultrusion profiles an ideal choice for outdoor applications, where exposure to sunlight and harsh weather conditions is prevalent. Additionally, the pultrusion manufacturing process ensures that the color of FRP profiles remains consistent throughout their entire cross-section. Consequently, even in the presence of minor surface damage or wear, the underlying color of the profile remains unchanged, ensuring a uniform appearance. In summary, FRP pultrusion profiles offer unparalleled resistance against fading and discoloration, making them a resilient and long-lasting option for a wide range of applications, including construction, infrastructure, transportation, and more.

- Q: How do FRP pultrusion profiles perform in chemical processing plants?

- Due to their outstanding performance in challenging environments, FRP pultrusion profiles are extensively utilized in chemical processing plants. Specifically engineered to endure the harsh conditions prevalent in such facilities, these profiles are favored over traditional materials like steel or concrete. One key benefit of FRP pultrusion profiles in chemical processing plants lies in their remarkable resistance to corrosion. These profiles exhibit a high level of resistance to a diverse range of chemicals, including acids, alkalis, solvents, and highly corrosive substances. This resistance ensures the profiles' durability and integrity even in aggressive chemical environments, subsequently decreasing maintenance costs and prolonging equipment service life. Moreover, FRP pultrusion profiles boast exceptional mechanical properties, such as a high strength-to-weight ratio. This enables them to bear heavy loads without compromising their structural integrity. Additionally, their lightweight nature facilitates easier handling and installation, thereby reducing labor and transportation expenses. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties, making them ideal for applications that require minimal electrical conductivity. This eliminates the risk of electrochemical reactions and ensures the safety of both personnel and equipment. Another advantage of FRP pultrusion profiles is their ability to provide effective thermal insulation. They effectively minimize heat transfer, thereby reducing energy loss and enhancing energy efficiency within chemical processing plants. Additionally, FRP pultrusion profiles are non-magnetic, making them advantageous in certain applications where magnetic interference could disrupt sensitive equipment or processes. In summary, FRP pultrusion profiles offer exceptional corrosion resistance, mechanical strength, electrical insulation, thermal insulation, and non-magnetic properties, making them exceedingly suitable for chemical processing plants. These profiles provide a cost-effective and long-lasting solution that can endure the demanding conditions encountered in chemical processing environments, ensuring reliable performance and reduced maintenance requirements.

- Q: Can FRP pultrusion profiles be used in aerospace applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in aerospace applications. These profiles offer a combination of strength, lightweight, and corrosion resistance, making them suitable for various aerospace components such as structural supports, fairings, and interior panels. Additionally, FRP pultrusion profiles have high fatigue resistance and can withstand extreme temperatures, enhancing their suitability for aerospace use.

- Q: Can FRP pultrusion profiles be used in the construction of safety barriers?

- Indeed, FRP pultrusion profiles prove to be highly effective in the construction of safety barriers. When it comes to safety barrier applications, FRP pultrusion profiles surpass traditional materials like steel or concrete in numerous ways. To begin with, the strength and durability of FRP pultrusion profiles are remarkable. With their high tensile strength, these profiles can withstand substantial loads and impacts without deforming or breaking. Consequently, they are well-equipped to endure the forces that safety barriers may face, such as vehicular collisions or other accidents. Moreover, FRP pultrusion profiles possess a lightweight nature. When compared to steel or concrete, FRP is significantly lighter, which facilitates transportation, installation, and handling during construction. The reduced weight of FRP also proves advantageous in terms of ease of installation and cost-effectiveness. In addition, FRP pultrusion profiles boast excellent corrosion resistance. Unlike steel, FRP remains impervious to rust or corrosion, which can compromise the barrier's integrity and safety over time. This makes FRP particularly suitable for safety barriers exposed to outdoor environments or harsh weather conditions. Furthermore, FRP pultrusion profiles are non-conductive and non-magnetic, which presents advantages in certain safety barrier applications. For instance, in areas where electrical or magnetic interference poses a concern, such as near power lines or sensitive equipment, FRP barriers can provide an additional layer of safety by avoiding potential electrical or magnetic hazards. All in all, FRP pultrusion profiles offer a dependable and efficient solution for constructing safety barriers. Their strength, durability, lightweight nature, corrosion resistance, and non-conductive properties render them a suitable choice for a wide range of safety barrier applications.

- Q: Can FRP pultrusion profiles be used in the construction of chemical processing equipment?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of chemical processing equipment. FRP offers excellent resistance to corrosion, chemicals, and high temperatures, making it a suitable material for such applications. The pultrusion process ensures that the profiles are strong, durable, and have consistent properties, making them reliable for use in chemical processing equipment where resistance to corrosive substances is crucial.

Send your message to us

FRP Pultrusion Profiles Fiberglass Grid for Stairs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords