FRP Pultrusion Machine Produce High Quality Pultrusion made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

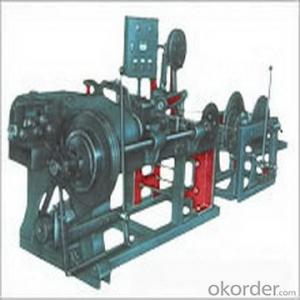

FRP Pultrusion Machine Produce High Quality Pultrusion made in China

Product Description:

The products are widely applied to green house, skylight, porch, door, sandwich panel,ceiling, transportation body, concrete form and liner panels.

Product Advantages:

1) Convenient and reliable installation, low construction expenses

2) Excellent heat-insulation property from minimum thermal conductivity

3) Light weight, convenient to transport and handle, good for labor-saving.

4) Smooth inner walls reduce pressure loss and increase flow speed

5) Excellent design ensure suitability for both exposed and hidden installation

6) Recyclable, environment-friendly, accords with GBM standards

Features:

1. Corrosion resistant

2. Light weight and high strength

3. Anti-ageing

4. Easy maintenance

5. Excellent electromagnetism property

6. Calorific property

Product Parameter:

Name | FRP Pultrusion Machine Produce High Quality Pultrusion made in China |

Brand | CMAX |

Weight | 6T |

Dimension(L*W*H) | 21.5*1.1M*1.2 |

Power | 15KW |

Voltage | 220V/380V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Pipe |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Blue |

Warranty | 1 Year |

Time of Delivery | 30-45 days |

Product Pictures:

FAQ:

Q: How about after-sales service ?

A: 12 month free warranty, Lifetime technical service support.

Q: How can I install the production line and get a commissioning ?

A: We may send our engineer for installation and commissioning, but relevant cost will be paid by you.

Q:Have you some videos where we can see the line producing?

A: Yes, we can provide some videos.

- Q: Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q: Processing method of PPS plastic

- 3, the automobile industry: PPS for automobile industry accounted for about 45%, mainly used in automotive functional parts; ignition, heater, vaporizer, clutch, gearbox, gear box, bearing bracket, lamp, bumper, fan, exhaust system and mirror and lamp seat parts. The utility model can be used for producing an exhaust cylinder, a circulation valve, a water pump impeller, a pneumatic signal adjuster, etc. in place of the metal. 4, household appliances: hot air dryer, hair curler, hair dryer, hair curler, microwave ovens, coffee pots, clothes dryers, electric irons, rice cookers and other protective coatings and parts. 5 、 chemical industry: PPS has good adhesion and corrosion resistance, it is very suitable for chemical equipment lining.Four. Material drying processTemperature: 100~105 DEG CTime: 3hr2 、 injection molding process1) die temperature: 60-80 DEG C2) material barrel temperature: front section: 220~260 centigrade middle section: 290~310 DEG C, rear section: 300~320 DEG CNozzle: 290~300 DEG C3) injection molding pressure: 60~70Mpa4) injection speed: medium speed5) injection molding time: according to the size of the workpiece to determine, in order to fill the mold, and the surface of the basic cooling is preferred

- Q: Plastic POM POM generally used for the production of what plastic products?

- Fire regulating ring, support member, gear, rack, rubber wheel, remote control switch bracket, cam pressure bar, cosmetic container, toy car runner, mobile phone chute

- Q: What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q: I'd like to open a waste plastics processing plant. What should I pay attention to? What machines are greener? Can you find 5T every day?

- Ziyang Sichuan double plastic machinery factory is a professional manufacturer of plastic machinery, and our latest environmental protection plastic granulator (smoke extraction system) can achieve no smoke in the process of granulation. Welcome to visit our factory at any time.

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- Plastic is basically non-toxic, but there are several special raw materials, heating will produce toxic gases, but little harm.

- Q: Plastic machinery plastic pellet production process _ particles recycled plastics particles

- 31. The preparation method of granulated antioxidant for plastic processing32. A new technology for producing inorganic filling granules for plastics33, bactericidal plastic particles and processing methods34. Method and apparatus for producing porous aluminum alloy with high porosity through plastic particles35. Use of nanoparticles to form thermoplastic foam in order to control the morphology of the bubble36. The spherical particles are prepared by the plastic melt37. Plastic packaging with micro particle markers38. Rotating cutters for granulate plastic castings39, plastic conductive particles and preparation method thereof40. The method of filling and unloading containers by plastic granular materials41. Method and apparatus for crystallization of adhesive particles, especially PET and PU particles42, a long fiber reinforced plastic particles rolling production device43, waste plastics recycling machine

- Q: What kind of machinery does a plastic product factory need?

- Provide materials for the construction project environmental impact assessment of construction project feasibility report, inform 1 (project proposal) or application report (must explain the project construction site, covers an area of, the amount of investment, production scale, production of raw materials and product content

- Q: Which kind is with a lid, hollow, a little like PP material, white is a little transparent. It used to be filled with oil or wine. How is it processed? What company has custom-made?. Need to make the tank.

- Blow molding die processing, general plastic products manufacturers should have the ability to produce.

- Q: Plastics are processed into raw materials. How much raw material and energy do we need to process a kilogram of plastic?

- Is the necessary equipment for extrusion blow molding machine, you must first set up the company, production workshop, production equipment, testing equipment, inspection personnel and production licenses for the government, as the raw material is plastic particles, costs and profits can not be known, see you how to operate.

Send your message to us

FRP Pultrusion Machine Produce High Quality Pultrusion made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords