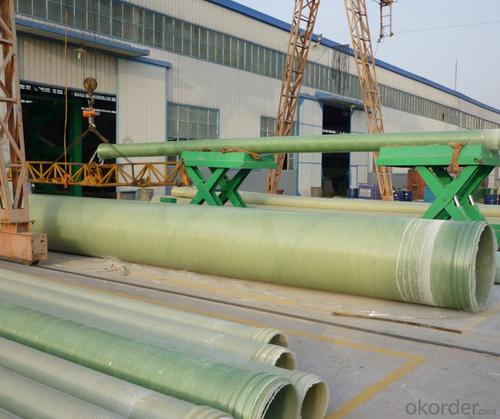

Composite FRP Pipes with Double O Ring Sealing Joint for Convenient Pressurization

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COMPANT DESCRIPTION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology & management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.Packaging Details:

standard packing or your requirement

2.Delivery Detail:

Shipped in 25 days after payment

PRODUCT DESCRIPTION

1.Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.Characteristics

• Light weight

• Non toxic

• Maintenance free

• Long life span

• Double O ring sealing joint make the pressurization

more convenient and unique.

• Convenient and quick installation

• Long life of more than 50 years

3.Production Range

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced.

Also, we can provide the customized product according to user’s specific requirements.

4.Technical Data

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce frp machines and frp products.

2.Q:If can customzied by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarntee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

- Q: How can I replace the valve on the water supply pipe?

- Steel flanges, three way pipe fittings and single disk connector is connected, immediately install three branch pipe valve, and will be closed fittings and valves at the bottom with concrete pier support, in order to timely restoration of water supply.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe? What kind of material is good?

- There are two main functions of glass fiber reinforced plastic sand adding, one is to improve the rigidity, the other is to reduce the cost. These two aspects just agree with the municipal, the dosage is large, the pressure is low, and the underground and maintenance are few.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- This depends on what your medium is, the general food industry requires stainless steel, but the medium contains acidic substances, stainless steel is better than FRP corrosion resistance

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- 1, the quota valuation, wind pipe materials, such as the "loss" of galvanized steel has been included in the quota content, including the lap and material loss, making the wind pipe.2, when calculating the actual material, it can be calculated according to the calculation area of the air pipe * (1+ fixed loss) = the actual amount of material used.

- Q: What is the difference between glass tube, sand pipe and glass tube?

- The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: What are the specifications of glass fibre reinforced plastic cable pipes? What are they?

- Strong corrosion resistance, insulation, non magnetic, acid, alkali, flame retardant, anti-static. The utility model has the advantages of good elasticity of bending modulus, complete solution of the corrosion of the metal pipe, no distortion and elasticity, and the defects that the plastic tube is easy to aging and the impact resistance is poor. Good water resistance, can be used in damp or water for a long time without deterioration. Due to the specific properties of glass fiber reinforced plastic, the service life of the glass steel pipe is more than 50 years. The construction is convenient, in particular the repair project, the efficiency is particularly prominent, is the power cable communication cable engineering, municipal engineering and road underground cable is the most ideal protective device, the cable bridge across the river, the use of the most suitable and convenient.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Epoxy coal tar pitch is a kind of anti-corrosion form with high cost performance. The engineering test shows that the epoxy coal asphalt is used as cathodic protection.

- Q: What kind of diamond saw blade for cut glass steel pipe?

- Diamond saw blade is a kind of cutting tool. It is widely used in the processing of concrete, refractory, stone, ceramics and other hard and brittle materials. The diamond saw blade is mainly composed of two parts: matrix and cutter head. The matrix is the main supporting part of the bond of the cutter head, the cutter head is the cutting part during use, the cutter head can be in use and constantly consumed, and the matrix is not, the cutter head is able to cut the role because it contains diamond, diamond as the hard material of it friction cutting object is processed in the knife head. The diamond particles are wrapped in metal inside the cutter head.

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Ensure the solidification of glass steel products in a reasonable range, in general, glass fibre reinforced epoxy resin material curing degree if the use of amine curing agent, the best curing degree in the range of 135 degrees --150 degrees, polyester resin, Mohs hardness of about 60 is OK.

- Q: Excuse me, what standard does the glass fiber that check mechanical and electrical use accord with GB?

- It is a resin based glass fiber weight layer wound on the mandrel rotating on according to process requirements, and distance evenly between the fibers as Kamiishi Eisa in the sand layer.

Send your message to us

Composite FRP Pipes with Double O Ring Sealing Joint for Convenient Pressurization

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords