Composite FRP (Fiber Reinforced Plastic) Pipes for Gas-Onshore Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pipe Description

Made from the high quality corrosion resistant resin and continuous fiber winding without alkali, filament winding FRP pipe possesses the characteristics of lightness, high strength, distinguished corrosion resistance and expedient installation and maintenance etc.,

FRP Pipes were applied widely in the oil-field system of sewage treatment, electrical plant water circulation, water pipe with electric magma and projects of chemical engineering, metallurgy, and medicine processing etc.

This FRP pipe has been tested and well-operated till now in the oil-field of Zhongyuan, Shengli, Daqing, Jianghan and Liaohe long distance conveying pipeline and the system of sewage treatment and Tibet Yangbajing Electrical Plant, Pakistan Feisalamade & Keteli Electrical Plant and Qinshan Nuclear Power Station, and therefore enjoyed the applause of the customers.

Our company (headquarter in Jiangsu Province) has been the No. 1 in exporting composites products domestically, annual capability of 100,000 tons for pipes & tanks as well as 10,000 pieces of wind turbine blade, with branches in Thuringia of Germany, Liaoning province, Neimenggu Province, Gansu Province, Xinjiang Province and Sichuan Province etc.

We are the exclusive FRP manufacturer with rich experiences in cooperating with foreign companies worldwide, the only supplier that provides large-diameter FRP pipes to the nuclear power station. Sole company owning finite element analysis in China. 20 production lines are in good operation.

Main Features of the FRP Pipe

1. Underground,with resin mortar

2. Corrosion-resistant

3. Light weight

4. Long standard lengths

5. Extremely smooth bore

6. Precision sealability

7. Flexible manufacturing

8. High technology pipe design

9. High technology pipe manufacturing system producing pipe that

complies to stringent performance standards (AWWA, ASTM, DIN, EN,BS, etc.)

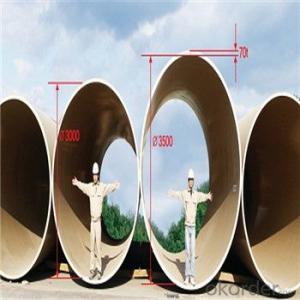

FRP Pipe Images

FRP Pipe Specification

Diameter: DN300-4000

Pressure:PN0-25

Stiffness: SN2500-10000

Standard length: 6m, 11.6m

Execute standard: AWWAC950,BS,ASTM and ISO.

Management System & Certificates

Management system: ISO9001, ISO14001, OHSAS18001,

Performance standards: ASTM D3262, D3517, D3754/AWWA C950, M-54/China Standard B/21238, JC552, CECS190, CECS129; DIN16868/ BS 5480;

WRAS Certificate, API Certificate, Installation Qualification.

We are the exclusive FRP manufacturer with rich experiences in cooperating with foreign companies worldwide, the only supplier that provides large-diameter FRP pipes to the nuclear power station. Sole company owning finite element analysis in China. 20 production lines are in good operation.

FAQ of FRP Pipe

Q: What can fiberglass pipe be used for?

A: Fiberglass pipes can be used for most piping applications, including: Plant and Process Piping, Firewater, Sewer (industrial & sanitary), Seawater Intake and Outfall, Desalination, Potable Water, Irrigation, Pre-insulated Chilled Water Piping, Jacking & Microtunneling, Manhole & Structural Liners, Tanks of all types (chemical & other), Conductive Piping (for hazardous areas), Offshore Piping, Fire-Resistant Piping, Abrasive-Resistant Piping, Ship and Dry Dock Ballast Piping, Marine and Subsea Piping (underwater), Air Vent Sewer Gas Ducting, Drop Shafts, Backdrops, Perforated Pipes, Oil and Gas Process Water, Downhole Threaded Tubing, High-Pressure Threaded Line Injection Well Tubing, Oil Well Casing and many more within the temperature capabilities of the resin.

Q: Are fiberglass pipes fragile?

A: Due to the elastic nature of the resin which holds the clothlike glass fibers together, fiberglass is strong and flexible. FPI products meet the rigorous "Impact Test" requirements of the international standard e.g. BS, API, ...

Q: Are fiberglass pipes an 'off the shelf' item?

A: No. FPI's fiberglass pipes are bespoke products engineered to the highest international standards and specifications.

- Q: Why FRP pipe corrosion?

- If it is ordinary water, generally does not count corrosion, there will be no obvious corrosion, long time began to soak rotten.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe? What kind of material is good?

- Sand tube is more brittle, gfrpmp is relative to the glass tube can be called pure glass tube, glass tube is not with quartz sand, the two pipes generally used in different areas, the pure glass pipe can be used in most areas, but the sand tube is generally only used in the political field, especially is the large diameter sand tube.

- Q: How can I make up the broken glass fiber?

- Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, as to the exact proportion, I just guess should be: curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth to make glass steel with good quickly, let the glass steel the glass fiber cloth fully soaked, waiting for the full glass steel after curing, and then repeated several layers. It will be strong.

- Q: What are FRP pipes?

- The pipe wall structure reasonable and advanced, can give full play to the role of material, to meet the premise of use strength, improve the rigidity, ensure the stability and reliability of the product.

- Q: Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- For nearly 20 years of brand silicone mold manufacturers, steel and glass also played nearly 20 years, glass steel pipe interface after grinding with water is Never mind, can be polished with water to the point where you can proceed to the next step of the operation of the glass steel bonding with a clean cotton cloth to wipe clean.

- Q: What is the structure and function of glass fiber reinforced plastic lining?

- The structure is made up of colloid + glass cloth. The construction process is like this:1, carbon steel inner wall grinding acute angle, rust removal2, brushing glue3, cloth affixed4, brushing glue5, cloth affixed

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Dislocation will cause the pipe to burst. The pressure is different, and the pipe will burst

- Q: What are the main points for the installation of FRP ducts?

- All you can think of public places, shopping malls, residential buildings, enterprises, institutions, etc., and so on, as long as the money, that can be installed

- Q: What kind of epoxy resin and formula do you need for making fiberglass pipe?

- This data mainly explains glass fiber reinforced plastics and other glass fiber reinforced materials manual forming process and all kinds of products.

Send your message to us

Composite FRP (Fiber Reinforced Plastic) Pipes for Gas-Onshore Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords