Pe Al Pe Composite Pipe - FRP Pipe Fiber Reinforce Plastic Pipe High Quality with Certificates

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

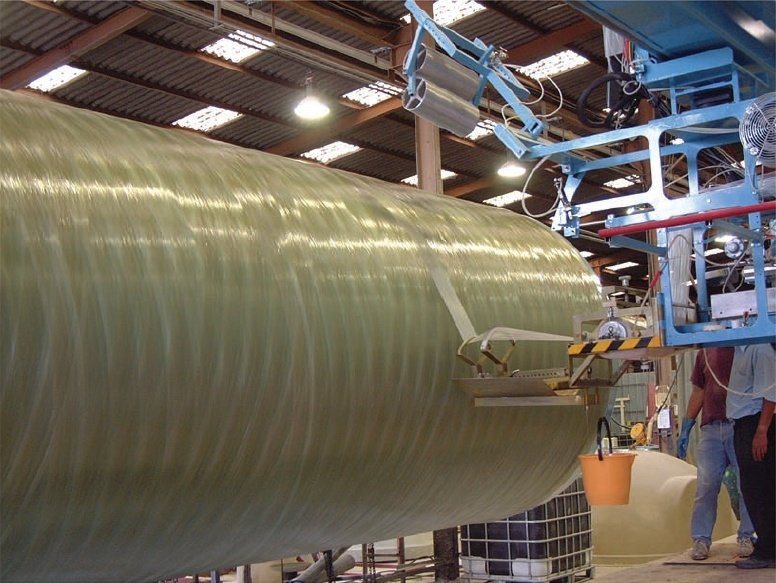

FRP Pipe Description

Made from the high quality corrosion resistant resin and continuous fiber winding without alkali, filament winding FRP pipe possesses the characteristics of lightness, high strength, distinguished corrosion resistance and expedient installation and maintenance etc.,

FRP Pipes were applied widely in the oil-field system of sewage treatment, electrical plant water circulation, water pipe with electric magma and projects of chemical engineering, metallurgy, and medicine processing etc.

This FRP pipe has been tested and well-operated till now in the oil-field of Zhongyuan, Shengli, Daqing, Jianghan and Liaohe long distance conveying pipeline and the system of sewage treatment and Tibet Yangbajing Electrical Plant, Pakistan Feisalamade & Keteli Electrical Plant and Qinshan Nuclear Power Station, and therefore enjoyed the applause of the customers.

Main Features of the FRP Pipe

1. Underground,with resin mortar

2. Corrosion-resistant

3. Light weight

4. Long standard lengths

5. Extremely smooth bore

6. Precision sealability

7. Flexible manufacturing

8. High technology pipe design

9. High technology pipe manufacturing system producing pipe that

complies to stringent performance standards (AWWA, ASTM, DIN, EN,BS, etc.)

FRP Pipe Images

FRP Pipe Specification

Diameter: DN300-4000

Pressure:PN0-25

Stiffness: SN2500-10000

Standard length: 6m, 11.6m

Execute standard: AWWAC950,BS,ASTM and ISO.

Management System & Certificates

Management system: ISO9001, ISO14001, OHSAS18001,

Performance standards: ASTM D3262, D3517, D3754/AWWA C950, M-54/China Standard B/21238, JC552, CECS190, CECS129; DIN16868/ BS 5480;

WRAS Certificate, API Certificate, Installation Qualification.

FAQ of FRP Pipe

Q: What can fiberglass pipe be used for?

A: Fiberglass pipes can be used for most piping applications, including: Plant and Process Piping, Firewater, Sewer (industrial & sanitary), Seawater Intake and Outfall, Desalination, Potable Water, Irrigation, Pre-insulated Chilled Water Piping, Jacking & Microtunneling, Manhole & Structural Liners, Tanks of all types (chemical & other), Conductive Piping (for hazardous areas), Offshore Piping, Fire-Resistant Piping, Abrasive-Resistant Piping, Ship and Dry Dock Ballast Piping, Marine and Subsea Piping (underwater), Air Vent Sewer Gas Ducting, Drop Shafts, Backdrops, Perforated Pipes, Oil and Gas Process Water, Downhole Threaded Tubing, High-Pressure Threaded Line Injection Well Tubing, Oil Well Casing and many more within the temperature capabilities of the resin.

Q: Are fiberglass pipes fragile?

A: Due to the elastic nature of the resin which holds the clothlike glass fibers together, fiberglass is strong and flexible. FPI products meet the rigorous "Impact Test" requirements of the international standard e.g. BS, API, ...

Q: Are fiberglass pipes an 'off the shelf' item?

A: No. FPI's fiberglass pipes are bespoke products engineered to the highest international standards and specifications.

- Q: Glass fiber reinforced plastic sand pipe backfill 5m, how much kg pressure?

- In general, glass steel pressure refers to the internal pressure, the conveying pressure of water, and you said the backfill produces is the external pressure, often say that the stiffness parameter.

- Q: What can be done to solve the leakage of FRP pipe?

- DN1800 FRP pipe pressure of 9 kilograms, the pressure is very high, crushed by stones, not repaired will certainly leak, the pressure pipe leakage is very bad, will be washed away the soil, spewing a few meters high water column.

- Q: What kind of project needs fiberglass pipe?

- Glass fiber reinforced plastic material has the advantages of corrosion resistance, high strength, low weight, and other materials can not be compared, the use of a wide range of purposes, such as water supply, chemical raw materials, hot and hot water transportation, ventilation and so on

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- The use of a fixed fare set without further consideration to duct losses has been included in the quota project

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- The service will be restored in 24 hours, and I hope this will help you! Can private letter to contact is not clear!

- Q: What is fiberglass communication tube?

- Fiberglass communication tubes are different from electric protective tubes. Glass fiber reinforced plastic communication tube is a composite structure, the inner layer of glass fiber burr cleaning, and brushing a thicker layer of resin, or lined with a layer of PVC.

- Q: What's the price of fiberglass reinforced sand pipes?

- Specifications: DN100--DN4000 are available.Thickness: 5mm--20mm, bothQ:28O5--9I343I/ I86+O38I+2OO7

- Q: What kind of diamond saw blade for cut glass steel pipe?

- Diamond saw blade is a kind of cutting tool. It is widely used in the processing of concrete, refractory, stone, ceramics and other hard and brittle materials. The diamond saw blade is mainly composed of two parts: matrix and cutter head. The matrix is the main supporting part of the bond of the cutter head, the cutter head is the cutting part during use, the cutter head can be in use and constantly consumed, and the matrix is not, the cutter head is able to cut the role because it contains diamond, diamond as the hard material of it friction cutting object is processed in the knife head. The diamond particles are wrapped in metal inside the cutter head.

- Q: What is the elastic modulus of glass fiber reinforced plastic?

- Glass fiber reinforced plastic is another name for glass fiber reinforced plastics, commonly known as FRP (Fiber Reinforced Plastics), that is, fiber reinforced composite plastic. Depending on the fiber used, glass fiber reinforced plastics (GFRP), carbon fiber reinforced plastic (CFRP), boron fiber reinforced composite plastics and so on are classified. It is a kind of composite material made of glass fiber and its products (glass cloth, band, felt, yarn, etc.) as reinforcing material and synthetic resin as base material. Fiber reinforced composites are composed of reinforced fibers and matrix. Fiber (or whisker) diameter is very small, generally below 10 mu m, less defects and smaller, fracture strain of about 30/1000, is brittle material, easy to damage, fracture and corrosion. The matrix is much lower in strength and modulus than fiber, but it can withstand large strains, often with viscoelasticity and elasticity, and is a ductile material.

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- Hebei, Qingdao and Beijing have additional production bases and service liaison points. Willing to work with new and old customers to create a beautiful today, Chinese and foreign. The company with integrity development guide thought, company value go production, learning and research Jimo road. The wide customers and cooperation of different geographical identity peer praise richly endowed by nature is a unique, Wuhua Tianbao, day people for the auspicious clouds. The sludge produced by the glass fiber reinforced concrete grille has good sedimentation, which is beneficial to the removal of the suspended substance in the back section. The glass fiber reinforced concrete grille has strong adaptability, can adapt to different water quality range, and has strong endurance to the shock load of water quality and water quantity sudden change. FRP grating treatment efficiency is higher than activated sludge process. The galvanized grating plate has the advantages of advanced structural design, optimum matching of gas and water, and sufficient heat exchange, with the same level in foreign countries and superior output. Galvanized grille plate steel bracket adopts zinc plating treatment, double paint anti-corrosion or electrostatic powder spraying, corrosion resistance is strong, service life over similar products double. The two-way grille ensures the natural delamination of the medium and the impurity, and at the same time, the discharge method is arranged at the bottom of the tank, so that the cleaning is particularly convenient

Send your message to us

Pe Al Pe Composite Pipe - FRP Pipe Fiber Reinforce Plastic Pipe High Quality with Certificates

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords