FRP Pultrusion Profiles:GRP Pultruded Gratings More Durable Than Stainless Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

Pultrusion is a continuous process to produce the random length FRP profiles with alike section, first to get the

fiberglass continuous roving and mat on creels through the resin bath under the traction of pultrusion machine,

then take shape through a pre-molding with a kind of section shape, and cured by heating die and finally

cooling and auto-sawing.

Pultrusion process is a kind of advanced mechanized compound materials molding process, which has the small environmental pollution, high production efficiency, small cutting loss and no waste leftover material, it could

produce random length FRP profiles with the alike section.

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Openspace (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

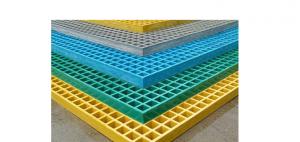

PICTURES

- Q: How do FRP pultrusion profiles perform in corrosive gas environments?

- In environments with corrosive gases, FRP pultrusion profiles exhibit outstanding performance. Their exceptional corrosion resistance, a notable characteristic of FRP, makes them highly suitable for applications that involve exposure to corrosive gases. Typically composed of a combination of glass fibers and a resin matrix like polyester or vinyl ester, FRP pultrusion profiles inherently possess corrosion resistance and do not react with most corrosive gases. Consequently, they can endure exposure to a wide range of corrosive gases, including sulfur dioxide, hydrogen sulfide, chlorine, and others. Furthermore, FRP pultrusion profiles excel in durability and long-term performance within corrosive gas environments. Unlike traditional materials such as steel or aluminum, they do not rust, corrode, or degrade over time. This corrosion resistance ensures the structural integrity of FRP profiles, even in harsh environments, thereby reducing maintenance and replacement costs. Moreover, FRP pultrusion profiles can be customized by incorporating specific chemical-resistant resins and additives. This customization allows for tailoring the FRP profiles to precisely meet the requirements of the application, ensuring optimal performance and longevity. In conclusion, FRP pultrusion profiles present an exceptional choice for environments with corrosive gases due to their remarkable corrosion resistance, long-term durability, and customization capabilities. They offer a reliable and cost-effective solution for industries such as chemical processing, oil and gas, wastewater treatment, and others in which exposure to corrosive gases is a concern.

- Q: How do FRP pultrusion profiles perform in extreme heat temperatures?

- FRP pultrusion profiles perform exceptionally well in extreme heat temperatures. Thanks to their advanced composition of fiberglass reinforced polymer, they possess high resistance to heat and can withstand temperatures well above 200°C without losing their structural integrity or mechanical properties. This makes FRP pultrusion profiles a reliable choice for applications where exposure to extreme heat is a concern.

- Q: What are the different types of FRP pultrusion profiles available?

- A variety of FRP pultrusion profiles are available to meet specific application requirements and performance criteria. These profiles include: 1. Standard shapes: These profiles are widely used in various industries and applications. They come in different sizes and shapes, such as round tubes, square tubes, rectangular tubes, and angles. Standard shapes offer versatility and are suitable for both structural and non-structural applications. 2. Custom profiles: These profiles are tailored to customer specifications. They offer flexibility in terms of shape, dimensions, and reinforcement options. Custom profiles are ideal for unique or specialized applications where standard shapes may not suffice. 3. Structural profiles: These profiles are designed for high strength and stiffness. They are commonly used in load-bearing applications, including beams, columns, and trusses. Structural profiles are reinforced with additional fibers to enhance their load-bearing capacity. 4. Electrical profiles: These profiles possess excellent electrical insulation properties. They find application in electrical and electronics applications such as cable trays, busbars, and insulating supports. Electrical profiles offer high dielectric strength and resistivity. 5. Environmental profiles: These profiles are formulated to withstand harsh environmental conditions, including extreme temperatures, UV radiation, and chemical exposure. They are commonly used in outdoor applications like structural supports, handrails, and grating systems. Environmental profiles offer long-term durability and resistance to degradation. 6. Fire-retardant profiles: These profiles are designed to have improved fire resistance properties. They are commonly used in applications where fire safety is crucial, such as building construction, transportation, and aerospace. Fire-retardant profiles incorporate additives that inhibit flame spread and reduce smoke generation. It is important to note that these are just a few examples of the FRP pultrusion profiles available. Depending on specific industry requirements, there may be other specialized profiles. The selection of the appropriate profile depends on factors such as the intended application, load requirements, environmental conditions, and regulatory standards.

- Q: Are FRP pultrusion profiles resistant to automotive fluids?

- FRP pultrusion profiles, commonly known as Fiber Reinforced Polymer profiles, possess a general resistance to automotive fluids. FRP, an abbreviation for Fiber Reinforced Polymer, is a composite material comprising a combination of fibers and a polymer matrix. The fibers utilized in FRP, such as fiberglass, carbon, or aramid, exhibit exceptional resistance to various automotive fluids, including oils, fuels, and coolants. The polymer matrix found in FRP profiles usually consists of a thermosetting resin, namely polyester, vinyl ester, or epoxy. These resins are renowned for their chemical resistance properties, which contribute to the high resistance of FRP pultrusion profiles towards a wide array of automotive fluids. They can endure exposure to different fluids without significant deterioration or loss of mechanical properties. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to automotive fluids may differ based on the resin type and the composite material's precise composition. As a result, it is advisable to consult the manufacturer or supplier of the FRP profiles to verify their suitability for the intended application and the specific automotive fluids they may encounter.

- Q: Can FRP pultrusion profiles be used in the production of electrical insulators?

- Yes, FRP pultrusion profiles can be used in the production of electrical insulators. FRP (Fiber Reinforced Polymer) offers excellent electrical insulation properties, high strength, and corrosion resistance, making it suitable for insulating applications in various industries, including electrical. The pultrusion process enables the production of customized profiles with consistent dimensions and properties, further enhancing their suitability for electrical insulator manufacturing.

- Q: Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in infrastructure projects. FRP pultrusion profiles offer several advantages over traditional materials such as steel and concrete. Firstly, FRP profiles are lightweight, yet still possess high strength-to-weight ratios. This makes them easier to transport and install, reducing construction time and costs. Additionally, their lightweight nature ensures they do not exert excessive loads on the supporting structures. Secondly, FRP profiles are corrosion-resistant. Unlike steel, FRP does not rust or corrode when exposed to harsh environmental conditions, making them ideal for infrastructure projects located in coastal areas or regions with high humidity. This corrosion resistance extends the service life of the structures and reduces maintenance requirements, resulting in long-term cost savings. Thirdly, FRP pultrusion profiles offer excellent durability and dimensional stability. They are highly resistant to fatigue, creep, and environmental degradation, ensuring the longevity and structural integrity of the infrastructure. Their dimensional stability also means that they maintain their shape and structural properties over time, reducing the risk of deformation or failure. Furthermore, FRP profiles can be customized to meet specific project requirements. They can be manufactured in various shapes, sizes, and strengths, allowing for versatile applications in infrastructure projects such as bridges, walkways, railings, support structures, and utility poles. Overall, the use of FRP pultrusion profiles in infrastructure projects offers numerous advantages, including lightweight construction, corrosion resistance, durability, and customization options. These benefits make FRP profiles a viable and cost-effective alternative to traditional materials for various infrastructure applications.

- Q: Can FRP pultrusion profiles be used in the telecommunications industry?

- Indeed, the telecommunications industry can use FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles have numerous advantages that make them appropriate for telecommunications applications. Firstly, FRP pultrusion profiles are both lightweight and immensely strong, making them perfect for telecommunications infrastructure. They can be utilized in the design and construction of structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles simplifies installation and maintenance, reducing the overall cost and effort involved in establishing and upkeeping telecommunications systems. Secondly, FRP pultrusion profiles possess exceptional corrosion resistance properties. This is especially crucial in the telecommunications industry, as infrastructure components are frequently exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, guaranteeing their durability and dependability in telecommunications applications. Moreover, FRP pultrusion profiles provide electrical insulation properties, which are essential in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications requiring electrical grounding or isolation. This characteristic ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be tailored to meet specific project requirements. They can be engineered with specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the unique demands of each project. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- Yes, FRP pultrusion profiles can be used in pedestrian bridges. FRP pultrusion profiles offer a number of advantages that make them suitable for bridge construction, including their high strength-to-weight ratio, corrosion resistance, and durability. These profiles are made by pulling continuous fibers through a resin bath and then through a heated die, resulting in a strong and lightweight material. The lightweight nature of FRP pultrusion profiles makes them ideal for pedestrian bridges as they can be easily transported and installed. Additionally, their high strength allows them to withstand the load requirements of pedestrian traffic. These profiles also have excellent resistance to corrosion, which is especially important for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance compared to traditional construction materials like steel or concrete. They are not susceptible to rust or rot, and their non-conductive properties make them safe for use in areas with electrical infrastructure. In summary, FRP pultrusion profiles are a suitable choice for pedestrian bridges due to their lightweight, high strength, corrosion resistance, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

- Q: Can FRP pultrusion profiles be used in the construction of chemical processing equipment?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of chemical processing equipment. FRP offers excellent resistance to corrosion, chemicals, and high temperatures, making it a suitable material for such applications. The pultrusion process ensures that the profiles are strong, durable, and have consistent properties, making them reliable for use in chemical processing equipment where resistance to corrosive substances is crucial.

- Q: What are the different surface finishes available for FRP pultrusion profiles?

- FRP pultrusion profiles offer several options for surface finishes that aim to improve the appearance, durability, and practicality of the profiles. 1. Smooth Finish: The smooth and glossy surface of this basic finish option creates a polished and clean appearance, which is ideal for applications requiring a sleek and professional look. 2. Textured Finish: Adding texture to the profile surface enhances grip and slip resistance, making it suitable for walkways, stairs, and ramps that require improved traction. 3. Anti-Skid Finish: Similar to the textured finish, anti-skid finishes provide superior slip resistance, making them ideal for areas exposed to wet or slippery conditions like marine environments, bridges, and industrial flooring. 4. UV Resistant Finish: Profiles exposed to outdoor environments can benefit from a UV resistant finish that safeguards against sunlight damage, preventing color fading, degradation, and loss of mechanical properties. 5. Fire Retardant Finish: Fire retardant finishes enhance the fire resistance of FRP profiles, making them essential in applications where fire safety is a concern, such as building construction, transportation, and electrical enclosures. 6. Colored Finish: FRP pultrusion profiles can be customized with colored finishes to match specific design or branding requirements, allowing for visual integration with the surrounding environment. It's important to note that the availability of these surface finishes may vary depending on the manufacturer and specific product. Consulting with an FRP pultrusion specialist or supplier can provide more detailed information on the available finishes and their suitability for various applications.

Send your message to us

FRP Pultrusion Profiles:GRP Pultruded Gratings More Durable Than Stainless Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords