FRP Corrugated Lighting Sheet From China !

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION:

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs

in china buiding materials industry. Established in 1984, CNBM is a large group corporation of building materials

with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely

owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,

professional service and complete solution to our customers. Strong delivery capacity, advanced technology

& management, strong financing capability and excellent after-sale service are our advantages in sharing

international market.

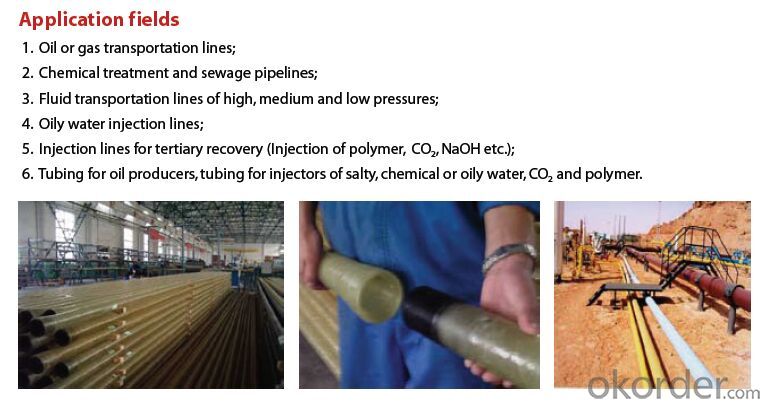

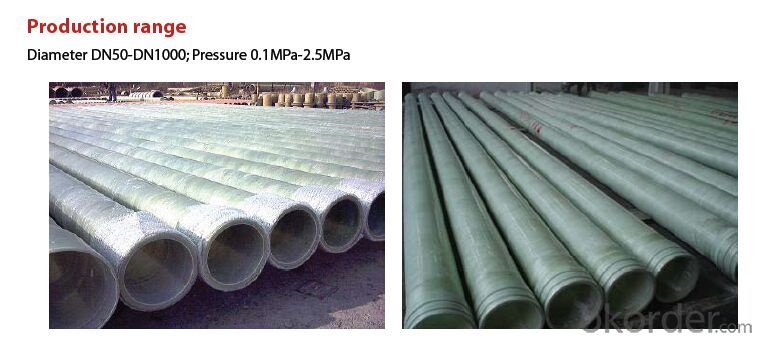

Our main FRP Products are as following;

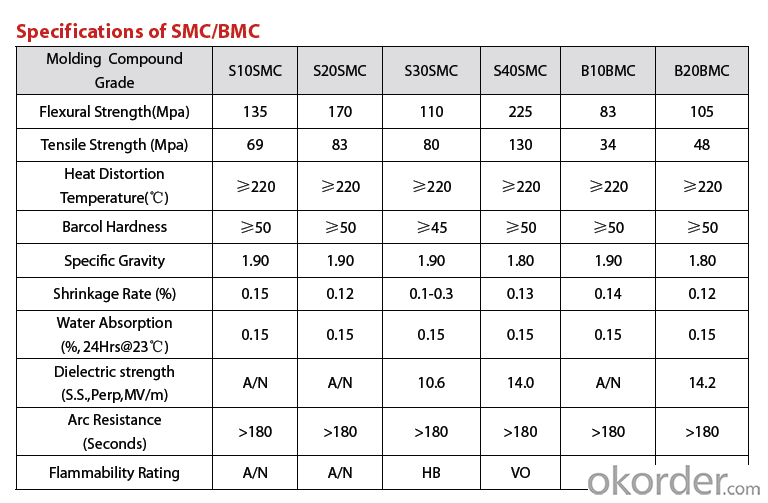

smc process:

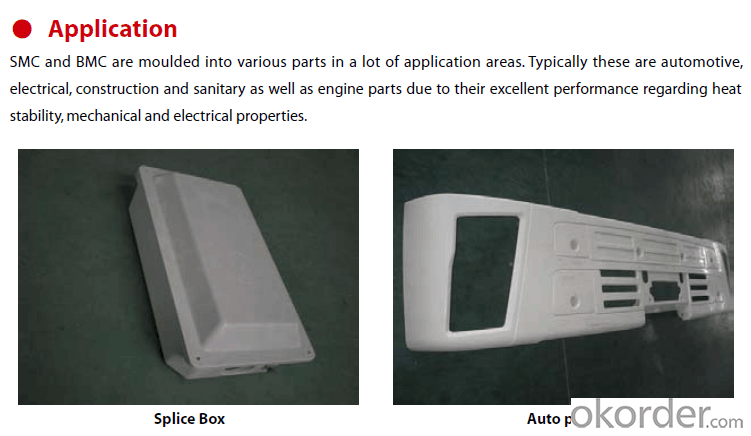

Sheet Molding Compounds (SMC) and Bulk Molding Compounds (BMC) are used in compression molding. SMC

or BMC compounds are place between matched metal dies representing the part shape. The mold closed and

under temperature and pressure, the compounds is cured. Compression molding is widely used in making car

body panels, truck cabs and other high volume large parts.

Sheet molding compounds (SMC) and Bulk Molding Compound

(BMC), which is a kind of material including, resin, filler, catalyst, mold

release agent and pigment, and glass fiber, with PE film on each side

of the material. On the basis of thickening , the PE film is peeled off,

the mixture inside is used while molding.

SMC is a fiber reinforced thermoset moulding material in the form

of Sheet, BMC is a fiber reinforced thermoset molding material in the

form of Bulk. SMC and BMC can be molded in way of compression.

SMC and BMC compounds are place between matched metal

dies representing the part shape .The mold closed and under

temperature and pressure, the compound is cured.

ADVANTAGES

1. Maintenance free:

A. Will not rust or rot

B. Will not crack due to cold

C. Flex with wind, snow and ice

2. Cost effective:

A. Save - on faster, easier installations

B. Save - on labor costs

C. Save-you will never have to re-stake trees again

D. Save - on replacement costs

E. Save-has a 25-30 year life expectancy

3. Profitable:

A. Allows max tree growth potential

B. Reduces chafing and cankers

C. Reduces tree damage.

Send your message to us

FRP Corrugated Lighting Sheet From China !

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords