FRM 770 series continous bag seaing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1. Description of the sealing machine

FRB-770 series plastic film continuous sealing machine is applicable to small bag seal.

2. Technical parameter

| Item | FRM-770I | FRM-770II | FRM-770III |

| Power supply voltage | AC 220/50 110/60 | ||

| Motor Power (W) | 50 | ||

| Electric Power (W) | 300 * 2 | ||

| Sealing linear speed (m/min) | 0 - 12 ( 0 - 16 ) | ||

| Sealing width (mm) | 12 | ||

| Temperature control range (degree) | 0 - 300 | ||

| Lettering category | Steel wheel indentation printing ( can choose ) | ||

| Seal center to transport station distance (mm) | 10 - 40 | 150 - 270 | 10 - 40 |

| Delivery table size | 840 * 153 | ||

| Delivery platform single maximum weight capacity (kg) | <= 1 | ||

| Delivery platform weight capacity (kg) | <= 3 | ||

| Overall Dimensions ( L*W*H)(mm) | 840*380*320 | 840*380*550 | 840*550*800 |

| Net weight (kg) | 32 | 47 | 40 |

3.Main features

Constant temperature controllable, the temperature is adjustable

Speed stepless adjustable

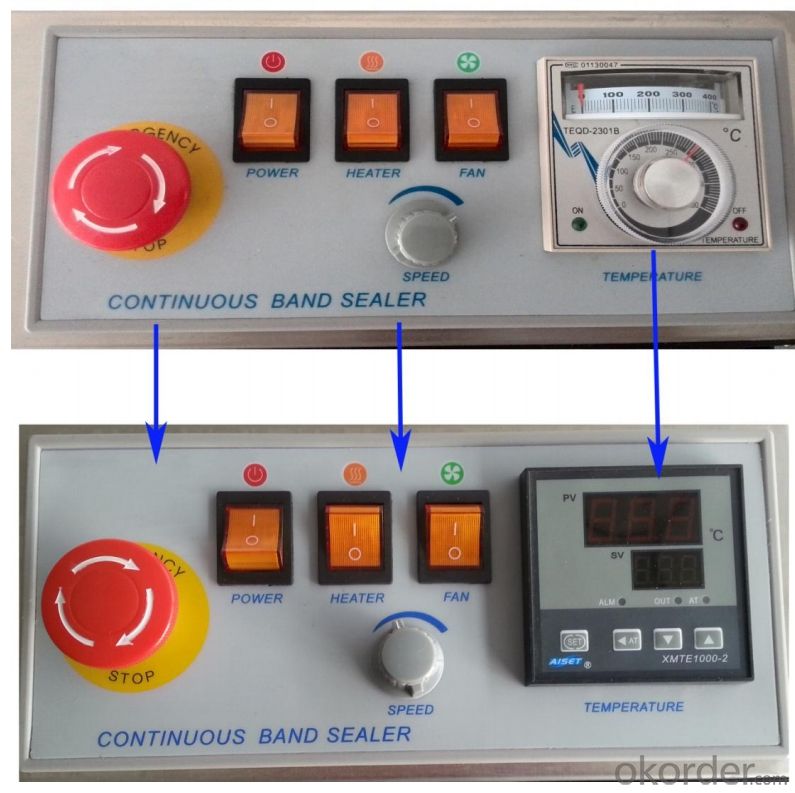

4. Images of the products

Model: FRM-770I

Model: FRM-770II

Model: FRM-770III

Detail image of the parts

Image of the finished sealed samples

5. FAQ

- Payment terms:100% by T/T

- Delivery time: 15 days

- Package: seaworthy plywood carton

- Guarantee period: 12 months

- Q: What is the design basis of automated packaging?! Just for today!

- 1. each manipulator is controlled by a single computer. A packaging machine for the completion of complex packaging operations, the need to be completed by a number of robot hand. When the package is completed, the information is monitored and controlled by the computer controlled camera, and the manipulator completes the required actions according to the instructions of the computer program to ensure the quality of the packaging.2. high resolution of material and thickness. In the packaging process, the thickness and material change in packaging materials is not easy for the human eye to identify changes in the design of packaging machinery is often used by the computer control of the camera and the detector to identify the thickness of packing material and material. The camera has now been developed to automatically check and identify pictures of the camera and display it on the screen. At present, the machine in the processing speed can not be changed, the future should be based on the change of the material through discrimination can change the speed, so as to control the work in the optimal state, complete the packaging process in the shortest time, and realize the automatic cleaning, automatic sterilization and automatic cleaning

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

FRM 770 series continous bag seaing machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords