Frequency Conversion Construction Hoist /Material Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

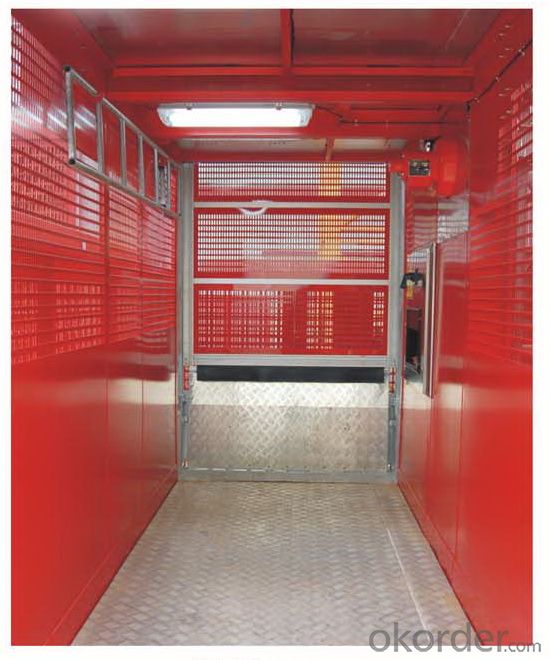

Our SC Construction Hoist is an industrial engineering elevator driven with pinion and rack, used for vertical transportation of materials, people and other heavy items, applicable to highrise building construction, storehouse, port, dock, tower, chimney and so on.

Features:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

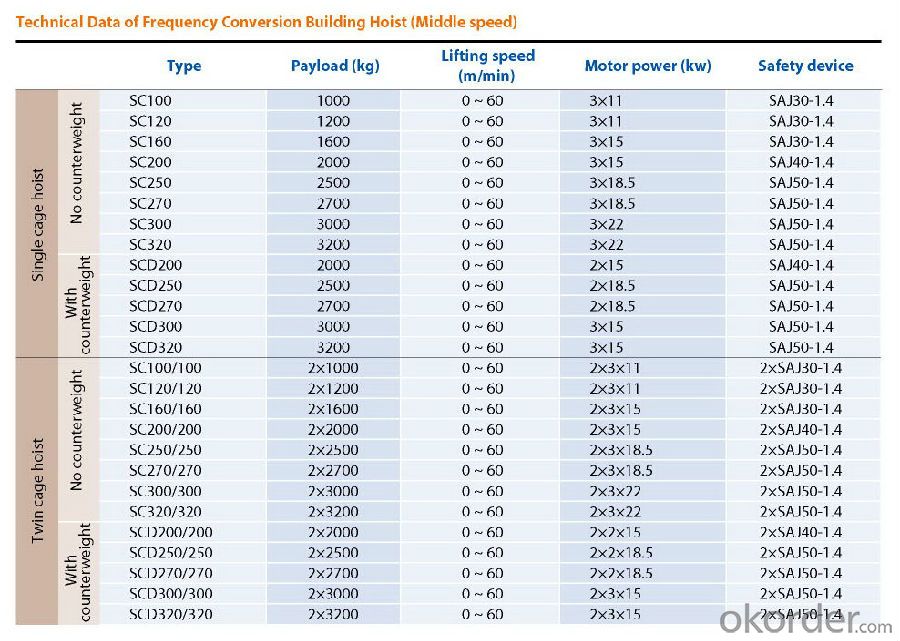

Specifications:

Recommended cage dimension (LXWXH): 2.0X1.0X2.5, 2.5X1.0X2.5, 2.5X1.3X2.5, 3.0X1.5X2.5, 3.2X1.5X2.5, 3.8X1.5X2.5, 4.0X1.5X2.5, 4.2X1.5X2.5 etc

- Q: Is it permissible to use a building hoist for lifting people?

- <p>Building hoists are not designed for lifting people and doing so can be extremely dangerous. They are specifically engineered for the transportation of materials and equipment in construction settings. Using a building hoist to lift people violates safety regulations and can result in severe accidents. Always adhere to the manufacturer's guidelines and local safety laws, which prohibit the use of building hoists for carrying personnel.</p>

- Q: Is it possible to fix a building hoist or substitute it with alternative lifting machinery?

- <p>Yes, a building hoist can be repaired if the damage is not severe. If repair is not feasible or cost-effective, it can be replaced by other types of lifting equipment. There are various alternatives available, such as cranes, forklifts, and material hoists, each with its own advantages and suitable for different scenarios. The choice depends on factors like the weight of the load, the height of the building, and the specific requirements of the construction project. It's essential to consider safety, efficiency, and compatibility with the existing infrastructure when making such decisions.</p>

- Q: This question asks about the various elements that can influence the efficiency and effectiveness of a building hoist.

- <p>The performance of a building hoist is affected by several factors including the type and weight of materials being lifted, the frequency of use, the hoist's mechanical condition and maintenance, environmental conditions such as wind and temperature, the skill and training of operators, and the design and capacity of the hoist itself. Proper installation, regular inspections, and adherence to safety protocols also play a crucial role in ensuring optimal performance and safety. Additionally, the quality of electrical systems, the efficiency of the drive mechanism, and the structural integrity of the hoist's components can significantly impact its operation.</p>

- Q: This question asks about the different types of hydraulic cylinders that are utilized in lifting equipment.

- <p>Hydraulic cylinders used in lifting equipment can be categorized into several types based on their design and application. The main types include: single-acting cylinders, which have one port for fluid and rely on the load or a spring to return; double-acting cylinders, which have ports on both ends and can extend and retract through fluid pressure; telescopic cylinders, which consist of multiple stages that can extend sequentially for greater reach; and rotary hydraulic cylinders, which provide a combination of linear and rotary motion. Each type is chosen based on the specific requirements of the lifting task, such as the need for speed, force, and control.</p>

- Q: Is it advisable to use personal lifting equipment without seeking professional advice first?

- <p>No, it is not advisable to use your own lifting equipment without consulting professionals first. Lifting operations can be hazardous and require specific knowledge and expertise to ensure safety. Professionals can assess the weight, stability, and appropriate lifting techniques required for your equipment. They can also provide guidance on safety regulations and the correct use of lifting gear, which is crucial to prevent accidents and injuries. Always consult with experts before undertaking any lifting tasks to ensure compliance with safety standards and to protect yourself and others.</p>

- Q: Is it possible to replace a lifting rope in a construction hoist with a regular rope?

- <p>No, a regular rope should not be used as a substitute for a lifting rope in a building hoist. Lifting ropes are specifically designed for heavy-duty lifting and have safety standards to ensure they can withstand the weight and stress. Regular ropes lack these safety features and can break under heavy loads, leading to accidents. Always use the appropriate lifting equipment as specified by safety regulations and the manufacturer's guidelines.</p>

- Q: This question asks for a comparison between electric and electric-hydraulic building hoists, highlighting their distinct features and how they differ from each other.

- <p>Electric building hoists are powered solely by electric motors, which provide direct and precise control over the lifting and lowering of loads. They are quieter, require less maintenance, and are more energy-efficient compared to their hydraulic counterparts. On the other hand, electric-hydraulic building hoists combine the power of an electric motor with the force amplification capabilities of hydraulic systems. These hoists offer greater lifting capacity and can handle heavier loads but are generally more complex, requiring regular maintenance of hydraulic components. They are also louder and may consume more energy. The choice between the two often depends on the specific requirements of the lifting task, such as load capacity, precision, and environmental considerations.</p>

- Q: This question asks for guidance on selecting appropriate lifting equipment based on specific requirements and work conditions.

- <p>To choose the right type of lifting equipment for your specific needs and work environment, consider the following: 1. Load capacity: Ensure the equipment can handle the weight of the items you need to lift. 2. Workspace: Evaluate the size and layout of your work area to determine the appropriate size and type of equipment. 3. Safety features: Look for equipment with safety features that meet your industry's standards. 4. Mobility: Consider whether you need a mobile or stationary unit. 5. Compatibility: Ensure the equipment is compatible with other tools or machinery you use. 6. Budget: Determine your budget and find equipment that offers the best value for your investment. 7. Consult with experts: Speak with equipment manufacturers or distributors to get their recommendations based on your specific needs. Always prioritize safety and efficiency when selecting lifting equipment.</p>

- Q: This question asks for guidelines on how to take care of lifting equipment after it has been used.

- <p>To maintain your lifting equipment after use, follow these steps: 1. Clean the equipment thoroughly to remove dirt, grease, and any debris. 2. Inspect all components for wear, damage, or signs of excessive use. 3. Lubricate moving parts as per the manufacturer's recommendations. 4. Check and tighten all bolts, nuts, and fasteners to ensure they are secure. 5. Store the equipment in a dry, clean, and well-ventilated area to prevent rust and corrosion. 6. Regularly review the manufacturer's maintenance schedule and perform any required servicing. 7. Keep a log of all maintenance and inspections to ensure you're staying on top of equipment care. Proper maintenance not only prolongs the life of your equipment but also ensures safety during use.</p>

- Q: Is it possible to replace an electric motor with a hydraulic cylinder in an electric-hydraulic lifting system?

- <p>No, a hydraulic cylinder cannot be used in place of a motor in an electric-hydraulic lifting system. A hydraulic cylinder is a component that converts hydraulic pressure into linear motion, while an electric motor converts electrical energy into mechanical energy. In an electric-hydraulic system, the motor drives a hydraulic pump, which generates the pressure needed to actuate the cylinder. The motor is essential for providing the power source, and the cylinder is the actuator that uses this power to perform work. Replacing the motor with a cylinder would result in a system without a power source, rendering it inoperative.</p>

Send your message to us

Frequency Conversion Construction Hoist /Material Hoist /Industrial Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords