Flux-cored Welding Wire AWS E71T-1 All Kinds of Welding Electrode

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. AWS E71T-1 Flux Cored Wire Introduction

Flux cored welding wire AWS A5.20 E71T-1 introduction: E71T-1 is a kind of TI type flux cored wire for CO2 welding ,it has high cladding efficiency, good welding technical performance in all-position welding, apply for low carbon steel and 500MPA grade strength steel welding, such as ships, pressure vessels, mechanical equipments and bridges.

2.Packaging & Shipping:

1kgs/spool/carton, 5kgs/plastc spool/carton, 15kgs/plastic spool/carton, vacuum packing

15kgs/box,72cartons/pallet,total 1080kgs/pallet.20-23 pallets /1x20' FCL

5kgs/box,200cartons/pallet,total 1000kgs/pallet.20-24 pallets /1x20' FCL

Application: Metallurgical industry, Bridge building, Building industry, Chemical industry, shipping industry

3.AWS E71T-1 Flux Cored Wire Specification

Mechanical Properties of Deposited Metal | ||||

Test Item | Rm(MPa) | ReL or Rp0.2(Mpa) | A(%) | KV2(J) |

Guarantee Value | ≥480 | ≥400 | ≥22 | ≥27(-20°C) |

General Result | 580 | 480 | 27 | 128 |

Chemical Composition of Deposited Metal (%)(CO2Shielding Gas) | |||||

Chemical Composition | C | Mn | Si | S | P |

Guarantee Value | ≤0.18 | ≤1.75 | ≤0.90 | ≤0.030 | ≤0.030 |

General Result | 0.05 | 1.46 | 0.42 | 0.01 | 0.017 |

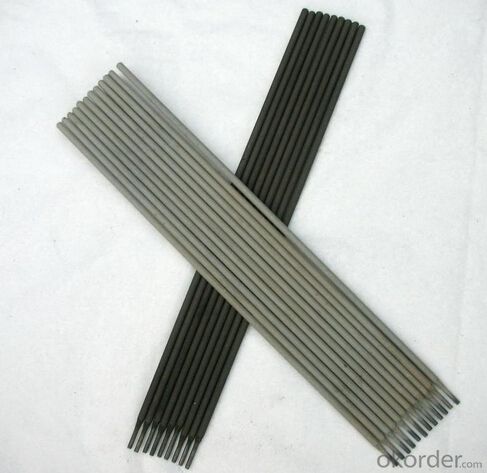

4.AWS E71T-1 Flux Cored Wire image:

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Who knows a package of ordinary 422 electrode, how many roots ah, small packets of that kind, a small package, how much money, I would like to know how much an average electrode, a little difficult

- 3.2 per kilo, 32 roots. 4 in diameter, 17 per kilogram. 5 in diameter, 11 per kilogram.5 kilos per package. Usually 20 kilos per box. (the difference is about 2.) 3.2 of the stores sell around 25 yuan a pack.An average of 0.156 yuan and 3.2 electrodes are considered.

- Q: What kind of welding rod used for HRB500 steel bars?

- What kind of welding rod used for HRB500 steel bars?Answer: if there is no design requirements, according to the electric arc welding joint form, please refer to "JGJ18-2012" Specification for welding and acceptance of article 3.0.3 of the:

- Q: How are the electrodes made up?

- Answer: welding rod is coated with the skin of the power supply arc welding melting electrode. It is composed of two parts covering and core wire. (L) cores. The electrode is metal cored coating called cores. The core is generally a certain length and diameter of the steel wire. When welding, the welding core has two functions: one is the conduction of the welding current, arc energy converted into heat energy; two welding core melting filler fused with the parent metal weld formation. The special steel wire used for welding can be divided into three categories: carbon structural steel, steel wire, alloy structural steel wire and stainless steel wire. (2) medicine skin. The pressure on the surface of electrode coating called coating. A coating of various minerals, such as minerals, is coated on the outside of the electrode to stabilize the arc and improve the quality of the weld. Some reducing agents should be added into the coating to restore the oxide to ensure the quality of the weld. Because of the high temperature of the arc, some of the alloying elements contained in the weld metal are burned (oxidized or nitrided), which reduces the mechanical properties of the weld. By adding ferrous alloy or pure alloy element to the electrode coating, it can be transferred to the weld metal with the melting of the coating, so as to compensate for the burning of the alloy elements and to improve the mechanical properties of the weld metal. It can improve the welding process performance, make the arc stable combustion, less spatter, good weld formation, easy slag removal and high deposition efficiency. In short, the role of the drug skin is to ensure that the weld metal to obtain the required chemical composition and mechanical properties, and make the welding rod has good welding process performance.

- Q: Can ordinary 422 electrode welding pig iron?

- No welding, it will crack, like the 2012 blockbuster film in the same terrible crack.

- Q: What type of welding rod is used for welding 16MnD?

- J507, preheat 150 degrees before welding, choose different welding current and voltage according to different wire diameter.2.5, 3.24575-100, 110-130, 150-165, 230-250

- Q: What kind of welding rod does aluminum alloy use?

- The seam is not much, should be brazed

- Q: Excuse me: can J422 welding rod not be used for HRB335 steel bar welding? Where there is such a rule, I see the norms can use ah.

- Lap welding, welding joint welding stress is too large, easy to break joints, it is not recommended. Welding steel bar has a special butt welding machine

- Q: What kind of welding rod is MG600? What about the performance? A lot of online sales, but one question is wrong, who knows that home is true?

- Special welding electrode for metal material MG660:Universal wide Cr-Ni high strength welding rod, welding can be almost a variety of commonly used steel, can satisfy the most stringent requirements, such as commonly used in tool steel, die steel, vanadium molybdenum steel, spring steel, spring steel and unknown, is also commonly used in inconsistent interface size steel. Excellent weldability, crack resistance, plasticity and toughness.Our company has, oh, do not worry, ha ha

- Q: Can 50Mn2 casting be welded with 507 electrodes?

- 50Mn2 is medium carbon steel, while J507 electrode is a low carbon component. If 507 electrodes are used to weld, the carbon content of the weld seam is lower, which will reduce the joint strength. Therefore, the welding of 50Mn2 steel with J507 welding rod can not guarantee the strength of the weld seam. It only applies to the welding of the weld when the strength of the joint is not high.

Send your message to us

Flux-cored Welding Wire AWS E71T-1 All Kinds of Welding Electrode

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords