Flux Cored Welding Wire E71T-1 Rutile Sand Coated Electrode Welding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Uses of Flux Cored Welding Wire E71T-1 :

For welding lowcarbon steel structures, especially suitable for welding on thin plates and cosmetic welding which requires the weld beads to be beautiful and glossy.

It has excellent welding performance, excellent operating performance, easy reignition, stable arc and beautiful appearance of weld.

Upholding principle of customer first, service paramount, keeping improving and creating win-win cooperation, CNBM provides welding consumables with excellent quality to domestic and oversea customers for significant projects such as utility boiler, pressure vessel, nuclear industry, aerospace, bridge engineering, boats and ships, vehicles, fossil oil, chemical industry, hydroelectric, thermal power, metallurgy, high-rise buildings, heavy mechanical equipment and offshore drilling platform.

2.Features of Flux Cored Welding Wire E71T-1 :

This fulx cored welding wire with welding in all position, stable arc, less spatter, excellent bead appearance and can be used for shipping, bridge building and various steel structure.

our products have been approved by CCS, ABS, DNV, LR, GL, BV, NK ,KR,CWB

3.Details of Flux Cored Welding Wire E71T-1 :

CHEMICAL COMPOSITION OF MELTING METAL(%)

C | Mn | Si | S | P |

≤0.12 | ≤1.60 | ≤0.75 | ≤0.035 | ≤0.040 |

Reference Current

Diameter(mm) | 2.5 | 3.2 | 4.0 | 5.0 |

Current | 90~120 | 120~150 | 170~200 | 210~250 |

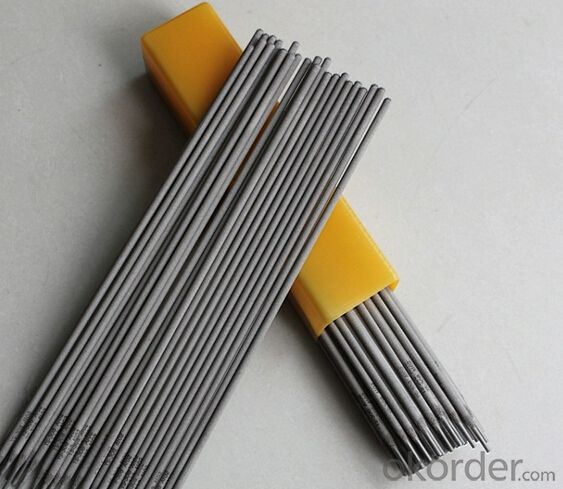

4.Image of Flux Cored Welding Wire E71T-1 :

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: 2.5 what is the current of the welding rod sheet?

- Welding sheet iron generally use 43 kg class acid electrode J422, current in 80-100A, welding thin sheet iron current should not be too small, the current is too small, but easy to weld through.

- Q: 400A DC inverter welding machine, suitable for long welding electrode

- Diameter 4 electrode.Inverter welding machine load rate is generally 60%, 60%, load rate of about 250 or above. Electrode selection current formula is the diameter of the welding rod x (33-55) times = welding current.220 the maximum electrode current is about 4. Current output of welding machine.

- Q: What is the difference between stainless steel welding wire and electrode?Such as;1, its welding effect or quality?2, how does it affect your body?3, its price and cost profit?The main topic of attention; he influence on the human body, (I once heard that the stainless steel has a great influence on man's reproductive function, welding of stainless steel welding technology do not know now there is no change?)

- You ask me a question I can't answer it clearly but you improve in this area we know the wire is generally used in the current relatively small range of welding point electrode is large current electrode current so penetrating some plate is too thick to burn in just so I need ordinary things welding welding wire electrode should die more expensive 1 kilograms of dozens of pieces of money is 304 if it is 202 kilogram 20 yuan, a package of electrode also dozens of pieces of money but few will not burn the wire can be used for a long time the two things can't compare you can only know them because they are some things have their own space welding they cannot replace each other?

- Q: How do you know it's a white steel electrode?

- Each electrode has a number of general Yilingjisanlingji is white steel 422 is carbon electrode 507 is 506 manganese steel electrode coating structure is just the most common can also see the skin color outside the carbon steel electrode is grey white steel is green and white are easy to distinguish

- Q: Welding rod heat preservation barrel should be clamped in the welding machine

- The output terminal of welding machine (or welding machine quick socket) is suitable for welding electrode barrel.

- Q: Can plastic welding rod weld PVC?

- It can be welded by heating weldingPVC as long as PVC, PVC is thermoplastic material, and can be welded with plastic welding rod.Can also be used without welding rod direct heating, with ultrasonic welding machine welding.

- Q: Why should the electrode be baked before use?

- I don't want to tell you anything that is very theoretical and very textbook. Our project is very wet in the south, so the steel production base often does.The main reason for baking the electrode is (or to prevent) the welding rod from being wetted.Welding rod after wetting, in the welding of workers will indirectly cause more slag, more bubbles, the current is not good control, burn the main tendons, and the strength of the steel bar connection will not meet the design requirements.That's all.

- Q: What kind of welding rod is MG600? What about the performance? A lot of online sales, but one question is wrong, who knows that home is true?

- MG600 is a universal, high efficiency, high strength chromium nickel alloy welding rod (welding wire). It has excellent plasticity, toughness and crack resistance. It is almost suitable for all kinds of common steel products. With excellent welding process performance, arc stability, easy to slag, less spatter, welding uniform and beautiful.Application: suitable for welding tools and moulds, high-speed tool steel, hot work tool steel, steel, cast steel, T-1 steel, steel, vanadium steel, seismic spring steel, martensitic stainless steel, austenitic stainless steel, ferritic stainless steel, and the unknown as well as between the various different types of steel welding etc.. Such as high pressure valves, broken bolt clearance, shaft transformation, etc., the effect is very satisfactory.

- Q: What does "E43" and "E50" mean by welding electrodes of steel bars? What is the exact shape?

- E43 series:E43, the tensile strength of the deposited metal is greater than or equal to 42MPa (430kgf/cm2)?E50 series:E50 series - the tensile strength of the deposited metal is greater than or equal to 49MPa (500kgf/cm2)?Specific shape: conventional drug skin, hand welding electrode.Turn left and turn right |

- Q: What is the corresponding brand number of electrode model E55?

- Welding rod model E55 * *, its brand is J55 * *, such as J507.

Send your message to us

Flux Cored Welding Wire E71T-1 Rutile Sand Coated Electrode Welding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords