Flat Wire Steel Mild Slitting China Prime Quality Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

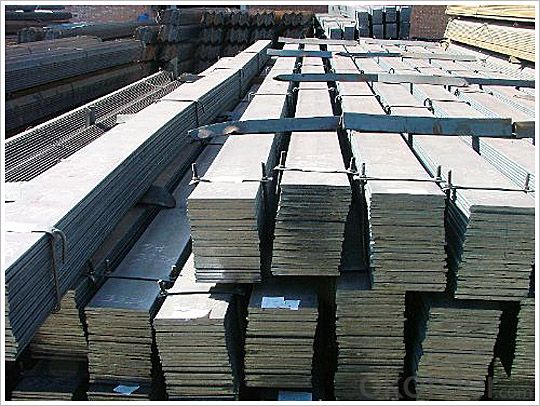

OKorder is offering Flat Wire Steel Mild Slitting China Prime Quality Carbon at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Wire Steel Mild Slitting China Prime Quality Carbon are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Wire Steel Mild Slitting China Prime Quality Carbon are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Size | Width | Tolerance | Thickness | Tolerance |

20 | 20 | +0.5 -1 | 2-4 | +0.3 -0.5 |

22 | 22 | +0.5 -1 | 2-4 | +0.3 -0.5 |

25 | 25 | +0.5 -1 | 2-6 | +0.3 -0.5 |

28 | 28 | +0.5 -1 | 2-6 | +0.3 -0.5 |

30 | 30 | +0.5 -1 | 2-6 | +0.3 -0.5 |

32 | 32 | +0.5 -1 | 2-6 | +0.3 -0.5 |

35 | 35 | +0.5 -1 | 2-6 | +0.3 -0.5 |

40 | 40 | +0.5 -1 | 3-6 | +0.3 -0.5 |

45 | 45 | +0.5 -1 | 3-6 | +0.3 -0.5 |

50 | 50 | +0.5 -1 | 3-6 | +0.3 -0.5 |

55 | 55 | +0.6 -1.3 | 3-6 | +0.3 -0.5 |

60 | 60 | +0.6 -1.3 | 3-6 | +0.3 -0.5 |

65 | 65 | +0.6 -1.3 | 3-10 | +0.3 -0.5 |

70 | 70 | +0.6 -1.3 | 3-10 | +0.3 -0.5 |

75 | 75 | +0.6 -1.3 | 3-10 | +0.3 -0.5 |

80 | 80 | +0.9 -1.8 | 3-10 | +0.3 -0.5 |

85 | 85 | +0.9 -1.8 | 6-10 | +0.3 -0.5 |

90 | 90 | +0.9 -1.8 | 6-10 | +0.3 -0.5 |

95 | 95 | +0.9 -1.8 | 6-10 | +0.3 -0.5 |

100 | 100 | +0.9 -1.8 | 6-12 | +0.3 -0.5 |

105 | 105 | +1 -2 | 6-12 | +0.3 -0.5 |

110 | 110 | +1 -2 | 6-12 | +0.3 -0.5 |

120 | 120 | +1 -2 | 6-20 | +0.3 -0.5 |

125 | 125 | +1 -2 | 6-20 | +0.3 -0.5 |

130 | 130 | +1 -2 | 6-20 | +0.3 -0.5 |

140 | 140 | +1 -2 | 6-20 | +0.3 -0.5 |

150 | 150 | +1 -2 | 6-20 | +0.3 -0.5 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the different types of surface defects that can be found in steel flat bars?

- There are several different types of surface defects that can be found in steel flat bars. These defects can vary in severity and may affect the overall quality and performance of the steel. Some common types of surface defects include: 1. Scale: Scale refers to the thin layer of oxide that forms on the surface of steel during the hot rolling process. While it can be removed through various methods, it may still leave behind a rough or uneven surface. 2. Pitting: Pitting is characterized by small, localized depressions or craters on the surface of the steel. It can be caused by corrosion, improper storage, or manufacturing processes. 3. Scratches: Scratches are visible marks or lines on the surface of the steel, which can be caused during handling, transportation, or processing. While they may not affect the structural integrity, they can impact the aesthetic appeal of the steel. 4. Lamination: Lamination refers to the separation or splitting of steel layers along the surface. It can be caused by poor quality control during manufacturing or excessive rolling. 5. Roll marks: Roll marks are repetitive patterns or lines on the surface of the steel caused by the rolling process. These marks can affect the appearance and flatness of the steel. 6. Inclusions: Inclusions are non-metallic substances that are trapped within the steel during the manufacturing process. These include oxides, slag, or other impurities that can form visible spots or irregularities on the surface. 7. Decarburization: Decarburization occurs when the surface of the steel loses its carbon content due to exposure to high temperatures or improper heat treatment. This can result in a softer or weaker surface layer. 8. Cracks: Cracks are visible fractures or breaks in the steel surface, which can be caused by excessive stress, improper cooling, or poor manufacturing practices. These defects can significantly compromise the strength and integrity of the steel. It is important to inspect and identify these surface defects in steel flat bars to ensure that the material meets the required specifications and standards. Depending on the severity of the defect, appropriate measures such as grinding, polishing, or even rejecting the material may be necessary.

- Q: Are steel flat bars suitable for architectural or interior design purposes?

- Yes, steel flat bars are suitable for architectural and interior design purposes. They are known for their strength, durability, and versatility, making them an excellent choice for various applications in design projects. Steel flat bars can be used to create modern and sleek designs, such as handrails, furniture, decorative accents, and structural elements. Their sleek and minimalist appearance can add a contemporary touch to architectural and interior spaces. Additionally, steel flat bars can be easily customized, bent, or welded to achieve desired shapes and designs, making them a popular choice among architects and designers.

- Q: Are steel flat bars suitable for load-bearing structures in bridges?

- Steel flat bars are well-suited for load-bearing structures in bridges. Due to their superior strength and durability, they are frequently employed in bridge construction. Their ability to endure heavy loads and offer exceptional structural support is noteworthy. Moreover, steel flat bars can be effortlessly welded or bolted together, facilitating efficient construction and convenient customization to meet precise bridge design needs. Additionally, these bars display resistance to corrosion, a vital attribute for bridge structures exposed to outdoor elements. All in all, steel flat bars are a dependable and economical option for load-bearing structures in bridges.

- Q: Are steel flat bars suitable for load-bearing shelves or brackets?

- Yes, steel flat bars are suitable for load-bearing shelves or brackets. They have high strength and durability, making them capable of supporting heavy loads without bending or warping. Additionally, steel flat bars provide a solid and stable surface for securely holding items on shelves or providing support for brackets.

- Q: How are steel flat bars used in construction?

- Steel flat bars are commonly used in construction for a variety of purposes. One of the main uses of steel flat bars is as structural support in buildings and infrastructure. They are often used as beams or columns to provide stability and strength to structures. Steel flat bars are also used for framing and bracing in construction projects. They can be used to create frames for walls, roofs, and floors, providing a sturdy framework for the rest of the building components. In addition, steel flat bars are utilized for reinforcing concrete structures. They are commonly embedded within concrete slabs or walls to enhance their strength and prevent cracking or structural failure. The bars act as tension members, distributing the forces evenly and improving the overall durability of the concrete structure. Moreover, steel flat bars are employed for manufacturing various construction components, such as brackets, connectors, and supports. These components are crucial for joining different elements of a building together, ensuring their stability and functionality. Overall, steel flat bars play a vital role in construction by providing structural support, reinforcing concrete, and manufacturing essential components. Their versatility, strength, and durability make them a preferred choice for many construction projects.

- Q: What are the different types of edge finishes for steel flat bars?

- There are several different types of edge finishes for steel flat bars, each serving a specific purpose and providing a unique aesthetic appeal. Some of the most common edge finishes include: 1. Mill Finish: This is the standard finish that steel flat bars typically come with. It is characterized by a rough, slightly rounded edge that has been left as is after the steel has been cut. 2. Deburred: In this edge finish, the rough edges of the steel flat bar are smoothed out using a deburring tool or process. This creates a cleaner and safer edge, reducing the risk of injury from sharp edges. 3. Rounded: In this finish, the edges of the steel flat bar are rounded off, giving it a smooth and curved appearance. This can be achieved through a variety of methods such as grinding or milling. 4. Beveled: Beveled edge finishes involve cutting or grinding the edges of the steel flat bar at an angle to create a sloping edge. This not only enhances the aesthetic appeal but also improves the bar's structural integrity and makes it more resistant to chipping or cracking. 5. Polished: Polished edge finishes involve buffing or grinding the edges of the steel flat bar to create a smooth and shiny surface. This can be done to achieve a mirror-like finish or a satin finish, depending on the desired appearance. 6. Chamfered: Chamfered edge finishes involve cutting or grinding the edges of the steel flat bar at a specific angle, usually 45 degrees, to create a beveled edge. This is often done to remove sharp corners and make the bar safer and easier to handle. These are just a few examples of the different types of edge finishes available for steel flat bars. The choice of edge finish depends on the intended use of the bar, the desired appearance, and any specific functional requirements.

- Q: Can steel flat bars be used in the construction of storage racks or shelves?

- Yes, steel flat bars can be used in the construction of storage racks or shelves. Steel is a strong and durable material that provides stability and support for storing heavy items. Flat bars can be easily shaped and welded to create the desired structure for storage racks or shelves, making them a suitable choice for this purpose.

- Q: How do steel flat bars perform in terms of strength and durability?

- Steel flat bars are known for their exceptional strength and durability. Due to their solid construction and high carbon content, steel flat bars exhibit superior tensile strength and resistance to bending, making them ideal for applications that require robust support or load-bearing capabilities. Additionally, their resistance to corrosion and wear ensures long-term durability, making steel flat bars a reliable choice for various structural and industrial purposes.

- Q: Are steel flat bars suitable for high-temperature environments?

- Steel flat bars are generally suitable for high-temperature environments, but the specific type of steel used and the maximum temperature it can withstand will depend on the application. Stainless steel flat bars, for example, are known for their excellent heat resistance and can be used in temperatures up to 1500°F (816°C). They exhibit good mechanical properties and can maintain their strength and shape even at high temperatures. However, it is important to consider the specific requirements of the high-temperature environment. Some factors to consider include the length of exposure to high temperatures, the presence of corrosive substances, and the potential for thermal expansion or contraction. In extreme cases, such as in furnace applications, specialized high-temperature alloys or refractory metals may be more suitable. It is always recommended to consult with a materials engineer or specialist to determine the best steel flat bar for a specific high-temperature application. They can assess the requirements and provide guidance on the appropriate steel grade, heat treatment, and any additional protective measures that may be necessary to ensure optimal performance in such environments.

- Q: 80 * 80 * 4 galvanized flat steel is what specifications?

- Galvanized square pipe.Specification: 80 * 80 * 4 is the dimension of galvanized square pipe. That is to say, the length and width of the inner diameter of the nozzle are 80mm, and the thickness of the tube wall is 4mm.

Send your message to us

Flat Wire Steel Mild Slitting China Prime Quality Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords