Cryogenic Insulation Paper - Flame-Retardant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Cryogenic Insulation Paper

Cryogenic insulation paper (P paper/Z paper)/aluminum foil (or aluminized polyester film) compositions are laminated of Cryogenic insulation paper and aluminum foil (or aluminized polyester film). Cryogenic insulation paper can be wrapped to the cryogenic inner tank directly and no need to composite by user. Therefore, cryogenic insulation paper can effectively reduce the waste of material and hugely increases efficiency. The width varies from 40mm to 1800mm.

Advantages of Cryogenic Insulation Paper

Flame-retardant

Light

High tensile strength

Low heat conductivity coefficient

Large thermal contact resistance

Low air content under the vacuum and broad operating temperature(-269℃-500℃)

Image of Cryogenic Insulation Paper

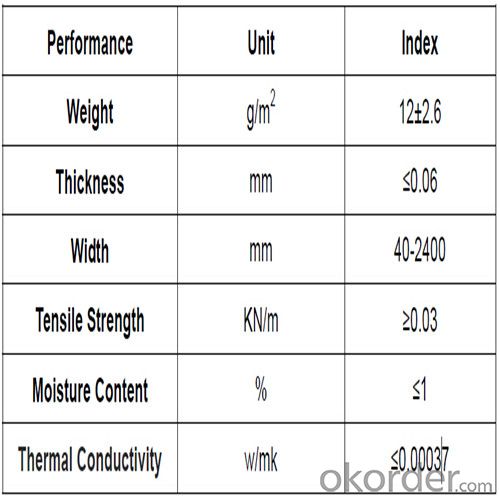

Technical Data of Cryogenic Insulation Paper

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: I would like to ask how the process of cryogenic treatment

- Biology: fast cooling, can prevent the crystallization of cells in the water, does not destroy the cell organization. In the preservation of sperm, organ preservation, food preservation, preservation of certain life and so onMedical treatment: cryotherapy, treatment of certain skin diseasesSpace: the space environment simulation, satellite ground test station, using liquid helium, create -200 degrees of low temperature.Noise: high sensitivity radar telescope, using liquid helium cooling, receiving device, noise reductionVacuum: the use of cold well technology can get high vacuum

- Q: Can the cryogenic phase control the cooling rate?

- 1, the principle of liquid nitrogen refrigeration: storage of liquid nitrogen in the container through the liquid in the sublimation of heat to take away the heat of the workpiece heat. Liquid nitrogen refrigeration can not be reused after the need to add a new liquid nitrogen, a large range of cooling rate, cooling temperature range of 0-196 degrees C.

- Q: How many changes in the properties of the cryogenic metal?

- Name material application effect1 the average number of W18Cr4V drill holes is 2.87 times that of untreated2 the number of drill holes in W6Mo5Cr4V2 twist drill is increased by 84%3 15 W18Cr4V from each processing to raise to4 M16 punching bit W12RE each 20 thousand to 40 thousand pieces5 M16 punching bit 65Nb each 1 thousand to 3 thousand pieces6 scissors T8, T10, T12 scissors silicon steel sheet life increased by more than 2 times7 milling 434 stainless steel blade C-2 carbide service life increased by 400%8 bearing steel GCr15 wear resistance increased by 3 times9 M3*0.5 Cr12MoV from a pair of processing to improve the 8000 pieces10 silicon steel sheet die Cr12 die life doubled11 hot stamping die 3Cr2W8V increased by 2.5% compared with the conventional AB, B increased by, AK increased by 4.9%12 M22 trimming die 012A1 each from 8000 to 30 thousand pieces13 processing silicon steel sheet die Cr12 processing sheet number increased from 300 thousand to 600 thousand

- Q: Cryogenic treatment to improve what performance?

- To improve the hardness and strength of the workpiece;Ensure the dimensional accuracy of the workpiece;Improve the wear resistance of the workpiece;

- Q: Ultra low pressure casting mold useful, how to arrange the process? Thank you

- Ultra deep cryogenic treatment process is mainly to eliminate the uneven stress in the process of heat treatment!Cryogenic treatment is mainly to eliminate internal stress or even internal stress! Can play a role in stabilizing the size!

- Q: What is the meaning of vacuum cooling in heat treatment

- Use a low temperature of 100 degrees below zero

- Q: What is a cryogenic fast line

- Cryogenic metal industry technology refers to the black metals, nonferrous metals, polymers, carbide and so on at cryogenic temperature heat preservation material, make it happen at room temperature and never happened in the process of heat treatment of the internal structure change, lead to the change of macro performance. For example: die steel, high speed steel, cemented carbide strength and toughness were improved after cryogenic treatment, and break through the traditional hardness and toughness of contradictory phenomenon, show the comprehensive performance improved. Domestic contribution to cryogenic technology research institute of Chinese academy of sciences, is the biggest should from the several aspects, such as equipment, mechanism, process research and extension of cryogenic technology, cryogenic in cutting tools, moulds, valves, and other industries extensively with the Chinese academy of sciences of physics and chemistry ? all the inseparable relations

- Q: What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- High speed steel W18Cr4V cryogenic hardness, impact toughness and wear resistance are significantly improved with the use of its manufacturing tool life increased by 2~5 times

- Q: What is the meaning of deep frozen

- Frozen food can make the flavor and nutrient retention is best, and it is said that at -35 deg.c, food oxidation reactions are very slow, that is to say deep freezing over the food nutrition and flavor of fresh food with little difference. In short, deep frozen to fresh.

Send your message to us

Cryogenic Insulation Paper - Flame-Retardant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords