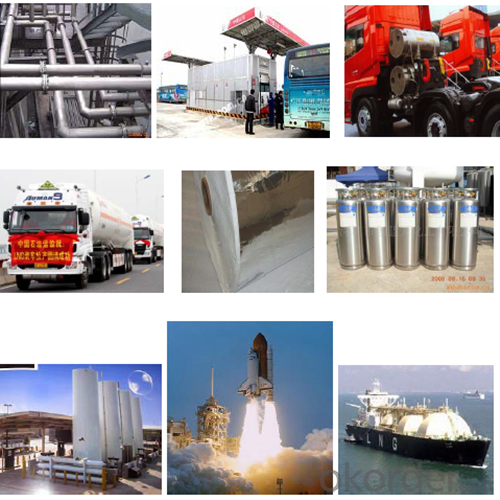

Cryogenic Insulation Paper - Aluminum Foil Laminated for LNG Vessel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Foil Laminated Cryogenic Insulation Paper for LNG Vessel

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Application: | high-vacuum multilayer thermal insulation | Surface Treatment: | raw material or customer customized | Dimensions: | z paper |

| color: | white |

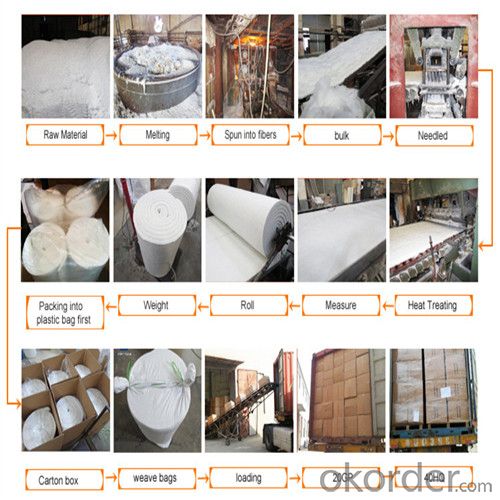

Packaging & Delivery

| Packaging Details: | by rolls,export normal packing with plastic bag and carton box |

| Delivery Detail: | 7-15 Days |

Specifications

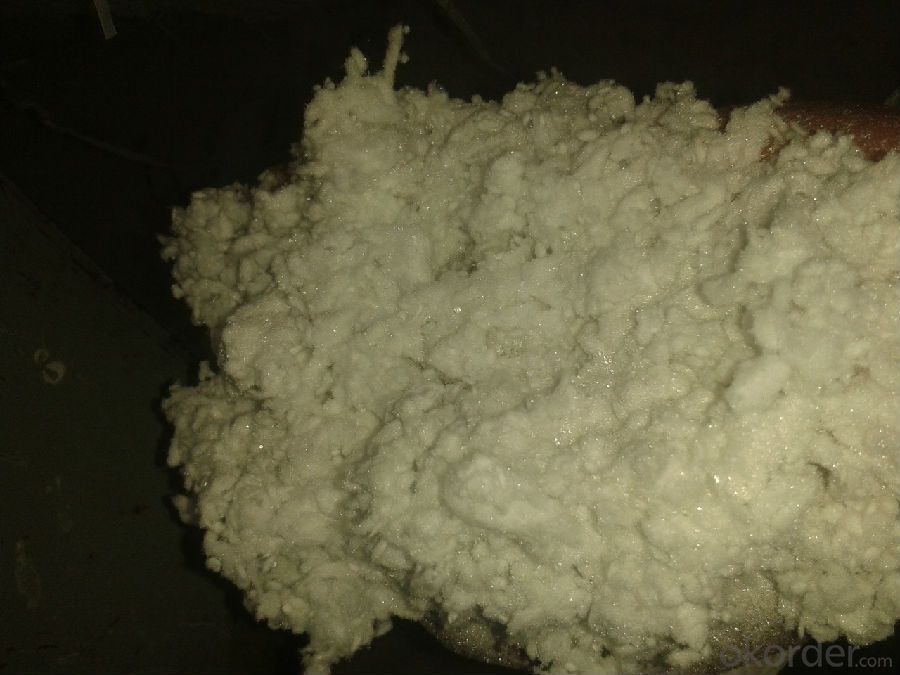

Aluminum Foil Laminated Cryogenic Insulation Paper

1.light weight

2.good uniformity

3.low thermal conductivity

Insulation Blanket:

Cryogenic insulation paper/radiation shield compositions:

Cryogenic insulation paper(P paper/Z paper)/aluminum foil(or aluminized polyester film) compositions are laminated of Cryogenic insulation paper and aluminum foil(or aluminized polyester film).These products can be wrapped to the cryogenic inner tank directly and no need to composite by user. Therefore ,it can effectively reduce the waste of material and hugely increases efficiency. The width varies from 40mm to 1800mm.

Specification

| technical specification | aluminum foil | aluminized polyester film |

| condition | anneal | vcauum aluminizing |

| Thickness | 0.0065 | 0.012 |

| surface oiliness | without oil, not less than calss B on brush water test | No oil |

| Harmful Element(%) | Pb<0.01 Cd<0.01 As<0.01< span=""> | / |

| Width | 30-1780 | 30-1780 |

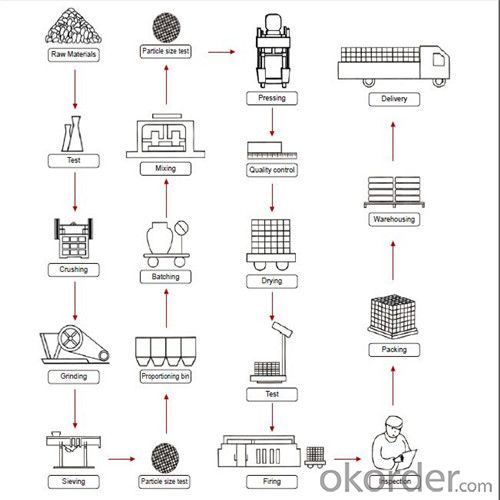

Our production

Our honour

Application

Other Insulation products:

Sample is on your request!

Welcome to visit our factory!

- Q: I would like to ask how the process of cryogenic treatment

- The air is compressed to 0.5MPa, or 22.5MPa, can reduce the water cooling, after expansion machine (piston or turbine), the temperature dropped to close to the liquid temperature to the fractionation tower after liquefaction, become rich liquid, the liquid oxygen into a fractionating tower, liquid oxygen, nitrogen is directly sent out after heat exchanger. Inlet air cooling.

- Q: Can the cryogenic phase control the cooling rate?

- 2, the compressor refrigeration principle: the use of the suction pipe of refrigerant gas inhalation of low temperature and low pressure, through the operation of the motor drives the piston to compress it after high temperature and high pressure refrigerant gas discharge pipe to the exhaust, to provide power for the refrigeration cycle, so as to realize the compression, condensation, expansion and evaporation (endothermic) refrigeration cycle. The refrigerant of the compressor can be repeatedly used for a plurality of times, the consumption is relatively small, the power consumption in the refrigeration process is more, the cooling rate is relatively small, and the refrigeration temperature range is 0-80 DEG C. The above mentioned two kinds of refrigeration in the process of industrial production of cryogenic box, the use of liquid nitrogen refrigeration will be more. Liquid nitrogen refrigeration can be used in the temperature range from 0 DEG C to -196 DEG C. []

- Q: How many changes in the properties of the cryogenic metal?

- The name of the processing content specification / processing content of the original service life (sub / piece) after the service life (times / pieces)1 milling cutter milling keyway 7.5-2NT 40034352 step drilling hole Phi: 1.2, 23, 1331004163 milling cutter milling air hole Phi 11.5, 32-2NT

- Q: Cryogenic treatment to improve what performance?

- Cryogenic treatment (cryogenic treatment) refers to the materials needed at -190 DEG C to -230 DEG C under treatment. Suitable for all metal or nonmetal material, such as alloy, carbide, plastic (nylon and Tie Fulong), aluminum, ceramics etc..

- Q: Ultra low pressure casting mold useful, how to arrange the process? Thank you

- Ultra deep cryogenic treatment process is mainly to eliminate the uneven stress in the process of heat treatment!Cryogenic treatment is mainly to eliminate internal stress or even internal stress! Can play a role in stabilizing the size!

- Q: What is the meaning of vacuum cooling in heat treatment

- Placed for a period of time, known as cryogenic treatment, under normal circumstances are usually treated with liquid nitrogen.

- Q: What is a cryogenic fast line

- Cryogenic metal industry technology refers to the black metals, nonferrous metals, polymers, carbide and so on at cryogenic temperature heat preservation material, make it happen at room temperature and never happened in the process of heat treatment of the internal structure change, lead to the change of macro performance. For example: die steel, high speed steel, cemented carbide strength and toughness were improved after cryogenic treatment, and break through the traditional hardness and toughness of contradictory phenomenon, show the comprehensive performance improved. Domestic contribution to cryogenic technology research institute of Chinese academy of sciences, is the biggest should from the several aspects, such as equipment, mechanism, process research and extension of cryogenic technology, cryogenic in cutting tools, moulds, valves, and other industries extensively with the Chinese academy of sciences of physics and chemistry ? all the inseparable relations

- Q: What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- Treatment of -130 DEG C is said to be a new and strong treatment process of cryogenic treatment to improve the wear resistance and toughness of materials and to improve the overall service life

- Q: What is the meaning of deep frozen

- So people use frozen ways to preserve food. Generally in a very short period of time, such as half an hour, so that the need to freeze the food quickly reach the specified ultra-low temperature, such as -30 ~-40 C.

Send your message to us

Cryogenic Insulation Paper - Aluminum Foil Laminated for LNG Vessel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords