Fireproof Calcium Silicate Board for Rotary Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Calcium Silicate Board for Rotary kiln Details:

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Type: | Non-Asbestos Fiber Cement B |

Packaging & Delivery

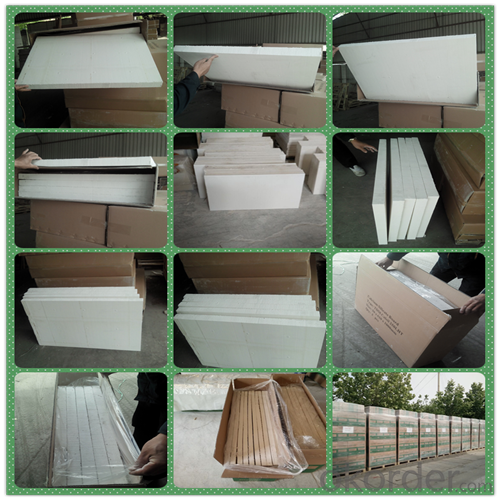

| Packaging Details: | wooden case in LCL, nake package in FCL |

| Delivery Detail: | 15 dyas after receipt of your deposit |

Product Description:

General information for Calcium silicate board:

CMAX calcium silicate products are classified under temperature between 650℃ to 1100℃, it’s an asbestos-free thermal insulation product.

Applications for Fireproof Calcium Silicate Board for Rotary kiln:

◆Reheating furnace

◆Annealing furnace

◆Transfer ladle

◆Rotary kiln

◆Glass tank

◆Shuttle kiln

◆Tunnel kiln

◆Aluminum melting and holding furnace

Main Product Features:

◆Low thermal conductivity

◆High thermal insulation value

◆High strength

◆High strength

Product Specifications:

| Size | Standard Size | 1220*2440*20/22/25mm |

| Appearance | Surface | Surface:Un-sanded |

| Edge | Square | |

| Physical Properties | Density | 1.4-1.6g/cm3 |

| Bending Strength | 16-21Mpa | |

| Moisture Movement | <0.20%< span=""> | |

| Water Absorption | < 20% | |

| Water Contain | <10%< span=""> | |

| Thermal Conductivity | 0.18-0.3 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | 20-25mm thickness is used for Floor & Mezzanine | |

| Average Bearing Loading(Refernce) | 2000kg/m2(distance between 12# Angle Bar is 610*610mm);1200kg/m2(distance between 12# Angle Bar 610*1200mm) | |

| Products Warranty | More than 20 years |

| Raw Material | |

| Cement | Quartz |

| Natural Fiber | Suspension |

| Composition of Finished Product | |

| Crystalloid of Calcium Silicate | Quartz |

| Calcium Carbonate | Cellulose |

FAQ

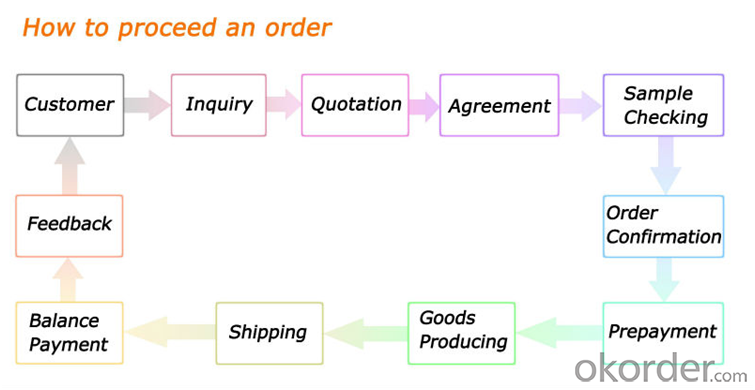

1. How to order ?

2.Can we accept OEM ?

YES! We can according your demand to produce.

3. Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, D&B and so on.

Our service:

üPrompt reply within 24 hours without delay by our specialized after-sale service sector.

üProvide high temperature solutions and professionals construction services for different fields for our customers.

üProvide the most reasonable logistics for customers to save every penny.

üProduction of goods are finished, thoughtful provide products and packaging photos for our customers.

Welcome to contact me for our Win-Win Cooperation!!!

- Q: My family in the north of the countryside, when the original building, the guest 粻 chicken class Tuen Jiu halo Mo hall with a high 1 meter wide and 50 cm tiles close to the wall around the circle, his wife said it looked good, do not want Yes, but the original is attached to the wall with cement, not easy to get down. I would like to ask, can not use gypsum board or plywood stick to the top, how to get, thank you! More

- Hurry to knock it! In the above coated with a layer of cement it!

- Q: Ceiling gypsum board and plastic plate which cheap?

- First to correct, the ceiling is not used plastic steel plate, nor is it upstairs that aluminum-plastic plate, it should be aluminum plate, aluminum buckle board has buckle, and side buckle. Personal feel side buckle look better. As for what you said cheap, it is certainly gypsum board cheap. But to see what you use, aluminum buckle board used in the kitchen or bathroom. Of course, gypsum board can also, but there is no aluminum gusset plate beautiful, and durable, floating the first Ju Ying Cape nail hair is also easy to scrub.

- Q: What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Calcium silicate does not meet this requirement

- Q: Decoration

- 1. Thermal insulation with calcium silicate board called microporous calcium silicate, is a white, hard new insulation material, with a light weight, high strength, small thermal conductivity, high temperature, corrosion resistance, can cut, Features. Widely used in electric power, metallurgy, petrochemical, construction, ship and other areas of equipment piping, wall roof insulation and fire insulation. Thickness is usually more than 30mm, the density of 200-1000kg / m3.2. Decorative calcium silicate board, the thickness of 4-20mm, length and width to 1220 * 2440mm mainly. Calcium silicate board (English: calciumsilicate) as a new green building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and industrial applications in the ceiling ceiling and Wall panels, home furnishings, furniture linings, billboard linings, shipboard trays, warehouses, floor panels, and tunnels. Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. It is a kind of new building and industrial sheet with excellent performance. Its products are fireproof, moisture - proof, soundproof, insect - resistant and durable, and it is an ideal decorative plate for ceiling and partition.

- Q: Export of calcium silicate board or gypsum board, which one shipping cheap?

- The problem is high. How is the freight? First answer the following questions 1. Air / sea / land / courier, etc. which you choose 2. From where to where 3. The volume of goods Fu tiger brother Xi Xi Ding Ding Ding busy gross weight 4. Start time to think These three questions and then look for freight forwarding companies, different ways of transport billing in different ways, such as shipping: General you can charter / bulk cargo container is also very thin 40 Pu 40 ultra high 20 small cabinet special cabinet (frozen What kind of) air there are two kinds of billing: give you 2 price XX yuan / kg XX yuan / party according to your weight and volume of goods are calculated to calculate which is your preferred. Different airlines have different Of the starting standards, and some less than one party by a formula, and some side by side by two formulas, so the three questions to find out, looking for a freight forwarding. So that you can have a more accurate freight

- Q: What is the difference between the silicate version and the calcium silicate board and whether the two materials are the same

- As far as I know, silicate board and calcium silicate board are two completely different products, please go to my space for details.

- Q: Please specify the specific time and the problem, thank you, calcium silicate board is Han Debang, medium density, colorful paint is Pan Cai, imitation stone more

- Calcium silicate board is a waterproof product, soaked inside the water and then long will not be soft

- Q: Decorative gypsum board is good or good calcium silicate board

- Gypsum board and silicate board has its own advantages and disadvantages: gypsum board: advantages: the relative ratio will be more than the order of the dry dry call sucking by environmental protection, easy construction, easy to crack, affordable; Disadvantages: Plate; silicate board: Advantages: good water resistance; Disadvantages: construction is not convenient cutting, dust easily harmful to the human body. Hope that "home staging" decoration can help you to help, hope to adopt!...

- Q: Ceiling, then the paper gypsum board, calcium silicate board, silicon calcium board three What is the difference, can recommend the next? The

- Ceiling gypsum board is better!

- Q: In the process of using the TK board or the use of silicon calcium board is the main choice is mainly to consider the bathroom waterproof and moisture-proof two kinds of materials which is more practical and economical Cost (cost)? General TK board how much money a plane, silicon calcium board about how much money a plane? More

- Toilet wall should be used (or processed to achieve) moisture-proof material, a good sound insulation performance; partition wall material requirements should be light, thin thickness, to adapt to the corresponding environmental requirements, drawn from local conditions. Wall can not afford to load-bearing role, only to separate the room and space of the wall, according to the different ways can be divided into block-type partition, vertical tendons, wall-type partition three categories. There are several kinds: light brick, glass tiles, glass, wood, gypsum board, new concrete slabs, ceramic plates, metal surface sandwich panels, etc., are also constantly developing innovation. Some of the non-waterproof material can be coated with a waterproof coating or past tile to enhance its water resistance. The reality is that the material is not expensive, expensive man. Plate prices from ten dollars to hundreds of dollars; and labor costs is basically two or three hundred. Therefore, according to local conditions to select the material process, improve production efficiency to save labor costs is the ultimate savings. If the project is large, through the factory production, on-site rapid installation can greatly reduce costs and improve competitiveness.

Send your message to us

Fireproof Calcium Silicate Board for Rotary Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches