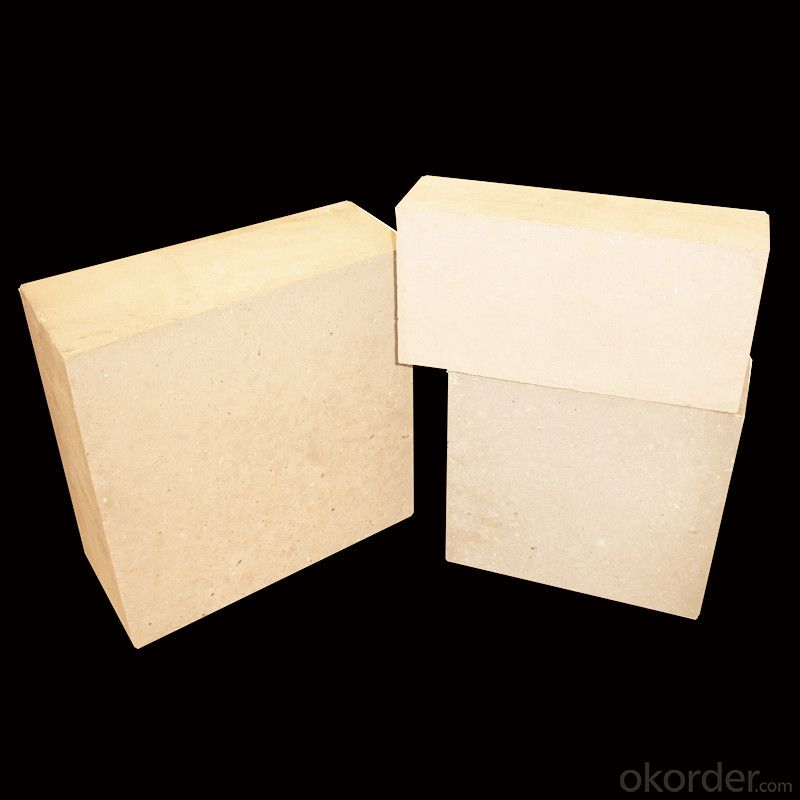

Fireclay Brick - Low Thermal Conductivity Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Knew Refractory Bricks Low Thermal Conductivity

Brief discription for End Knew Refractory Brick

CMAX End Knew Refractory Brick are classified according to alumina content ranging from 48% to 90%.

CMAX End Knew Refractory Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for End Knew Refractory Brick

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for End Knew Refractory Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

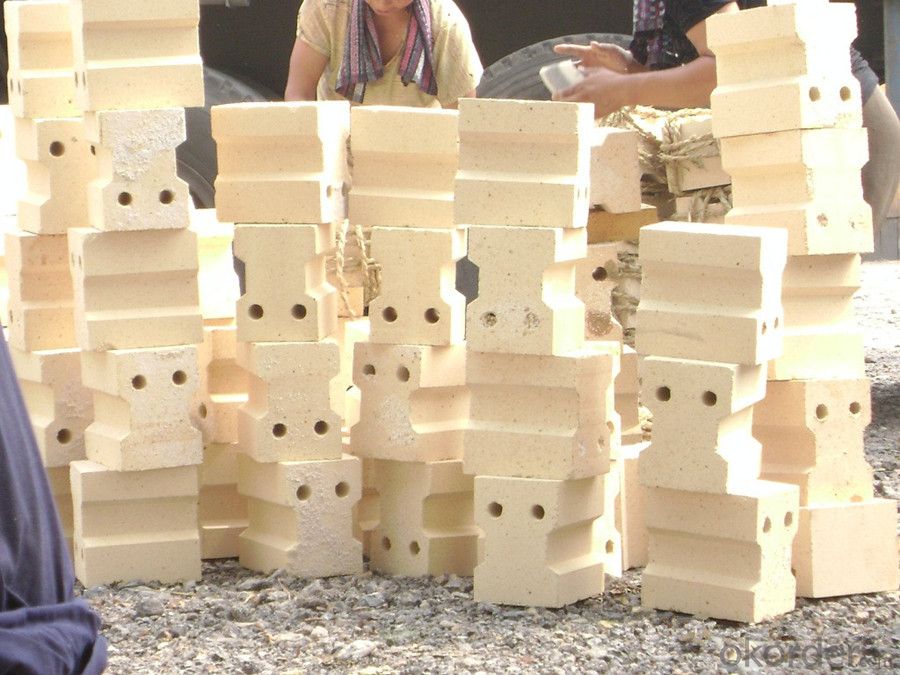

Images/photographs for End Knew Refractory Brick

◆ breif images-different shape for different usage

◆ Packaging for refractory bricks

◆ Producing Equipment for refractory bricks

◆ Testing Mashines for high alumina bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: does furnace use refractory cement to make refractory bricks?

- consistence Mainly concern about the strength, generally masonry mortar does not consider the degree of fire resistance

- Q: can the red brick be used as refractory brick?

- 1200---1750 of the refractory bricks, below 1000 degrees of red brick brick is ok.

- Q: Why limit sintering brick first and develop new wall material?

- Sintering brick in the production process, including fuel and many other aspects of pollution.

- Q: What to do if refractory bricks saltpeter when they are used outdoor

- Efflorescence is usually dialysised from brickwork joints, dealing with the gap is ok These white substaince inside the pan tile: Cement efflorescence efflorescence is wow cake section from light leather intestinal common disease inumiya Hua building surface, according to their different causes and manifestations, there is pan cream, white, whitening, cream, on the walls and decorative surface erosion and other names, is the change of soluble saline alkali soil, adobe, brick, cement, mortar, concrete, masonry, ceramic tile, paint and other building materials with temperature, humidity and other external environment, in a water absorption, water transfer, water evaporation process with physical and chemical changes of the original building material damage disease phenomenon, erosion degree also has the very big difference there is a common, get damp, foaming, powder, drum, hollowing, cracking, spalling, mildew and crystallization phenomenon. Cement efflorescence may have some relationship with the quality of the cement, sand, water, air, temperature, humidity, it is a common fault in building. Use cement to do the pebble shape, it also prones to the above problems: A layer of white stuff on the surface. Terms of settlement: Scrape the dust in brickwork joint, pointing again. Use special pointing agents, more resistant to corrosion, not easy to efflorescence.

- Q: Can common cement mortar be used to build the lining of chimney refractory brick?

- No. You have used fire bricks, which shows there is a certain temperature inside, you'd better use refractory cement

- Q: Why can't gravity retaining walls be made of clay bricks?

- Gravity retaining walls are usually made of mortar stone, but no clay bricks are used.No, I don't know. It's possible to use clay bricks instead of clay bricks

- Q: What are the properties of clay bricks?

- The clay brick belongs to weak acid refractory. Because of the fluctuation of chemical composition, the production method is different, and the difference of sintering temperature makes the properties of clay brick change greatly. Ordinary clay bricks are divided into (NZ) 1, 40, (NZ) 1, 35, (NZ) 1, 30, three trademarks on the basis of the amount of Al2O3 content in the components.

- Q: Red brick (solid clay brick) has been banned, why do few people know?

- Because everyone feels hollow brick is more advanced, it is for quality consideration only then change, won't be to think that regulation must use this, actually solid brick is better, won't have the risk of metope ooze water ~ but because environmental protection is not allowed to use

- Q: How good is the hardness of corundum refractory brick?

- The basic materials of corundum refractories are fused corundum or sintered corundum. the refractory brick containing more than 90% of Al2O3 is called corundum refractory brick. so, corundum refractory brick. Corundum has a high hardness (9 level of Mohs hardness) such as zirconium corundum refractory brick. Corundum refractory brick is resistant to acid well and melting point is also high, also known as pure alumina refractory brick products, , it has a good effect. These are closely related with the structure of the Al - 0 key, titanium corundum refractory brick, and other basic slag. It is used in high temperature oxidizing atmosphere or in reducing atmosphere. the metal and glass solution have good stability. a-Al2O3 is the main material of high temperature refractory brick and high temperature electrical insulating material .

- Q: MU10 what are the non clay solid bricks?

- Mu10 is the strength grade of bricks, divided into grades MU7.5, 10, 15, 20, 25, 30 and so on. Non clay brick "non sintered clay bricks, such as sand brick, shale brick, cement brick, fly ash brick etc..

Send your message to us

Fireclay Brick - Low Thermal Conductivity Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords