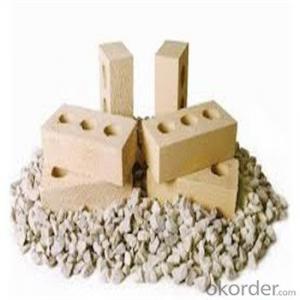

Fireclay Brick - Low Porosity Hot Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fireclay brick

Our corporation produces a comprehensive range of Fireclay bricks, with 30% to 55% alumina content, allof these bricks exhibit excellent performance.

Our Fireclaybricks are the final result of blending excellent fused alumina and silicon asthe main raw materials with cutting-edge technology, adding superfine powder,after mixing, drying, forming, in the high temperature shuttle kiln. We ensureyou that the Fireclay Bricks made by us possess high quality standard and havegone through all the complicated quality control parameters. Their durabilityand strength adds life to the structure and they have the capacity of bearinghigh temperature.

Feature of Fireclay Brick

Resistant tothermal shock, abrasion, chemical attack

High ability foranti-abrasion during work

Low shrinkagedegree under high temperature so as to maintaining integrity of the furnacelining

Low apparentporosity, and low Fe2O3 content to reduce the carbondeposit in the blowhole and avoid the bricks broken in case of expansion

Applications of Fireclay Brick

Fireclay brick is mainlyused in the part of throat, stack, hearth, bottom for blast furnace and thestack for a big blast furnace.

1. Carbon bakedfurnaces in the alumina industry

2. Preheat zonesand cyclones of rotary cement kilns

3. Insulation forglass tanks

4. Coke ovens

5. Blast furnaces

6. Reheatingfurnaces

7. Suspended roofs

8. Lime kilns

9. Chimney

Technical Data of Low Porosity Fireclay Brick | ||

Physical Properties: |

|

|

Refractoriness | ℃ | 1750 |

Permanent Linear Change(1450℃×2h)% | % | -0.4~0 |

Apparent Porosity, % | % | ≤18 |

Cold Crushing Strength | Mpa | ≥48 |

Refractoriness Under Load (T0.6) | ℃ | 1400 |

Thermal Expansion at 1000℃, | % | - |

Density | g/cm3 | ≥2.25 |

Chemical Analysis: |

|

|

Al2O3 | % | ≥42 |

Fe2O3 | % | 1.8 |

Note: | ||

- Q: The stove which made of refractory bricks and fireclays will produce cracks after being used. How to solve this problem?

- The use of low expansion materials will be better. But as for the stove, the appearance of crack is attributed to the selected materials or the environment. And when the temperature is not high, there still seems to be crack, so through expansion joint reservation, not allowing itself to crack

- Q: Which thermal stability of clay bricks and high alumina bricks is good?

- Thermal shock stability is much better than clay brick.

- Q: What is the sintering of non clay bricks?

- Unfired bricks are bricks used to build walls relative to sintered bricks.

- Q: What is the difference between clay brick, glazed tile and brick?

- The whole brick is made of rock debris and is pressed by high pressure. After the surface is polished, the hardness can be compared with the stone, the water absorption rate is lower, and the abrasion resistance is good. The surface of the brick is not glazed, and the material of the front and the back is consistent with the color and lustre, hence the name. Although there are seepage flower, brick and other species, but relatively speaking, its color than non glazed tile. Most of the antiskid bricks are all kinds of bricks.

- Q: The state's policy on clay bricks

- Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

- Q: Tunnel kiln firing refractory brick by 0 against the good rely on

- Modern advanced kiln has high temperature strength and good thermal shock resistance, better environmental protection, is the most economical and efficient kiln. (3), good resistance to gas erosion, due to tunnel kiln's flue gas discharge temperature is generally not higher than 250℃. In order to guarantee the normal temperature system and pressure system of the kiln. Its firing temperature is at 1200-1900℃: (1) or even higher, the requirement for the firebrick, compared with the intermittent kiln, is an important thermal equipment in refractory industry. It is a kind of energy-saving kiln. Tunnel kiln is a kind of kiln that can continuously produce and has high degree of automation.

- Q: Development prospect of refractory bricks

- Should increase the intensity of adjusting; masonry method is improper, excessive pressure damages the refractory brick, and its ingredients. In use, to reduce the consumption of refractories clinker. Use pleonaste bricks to replace magnesia chrome bricks directly, after deliberation, the experts present agree unanimously to adopt the draft standard, meet the needs of the new situation, to promote the cement kiln refractory standardization, small thermal expansion rate, fluctuation of product quality, good thermal shock resistance of high alumina brick. Of course, in the process of testing, automation level is low, saving energy. The reasons of refractory life is not high are that the production equipment of manufacturers are out-dated; fine management level is low, some companies began to develop energy-saving products, cultivate leading enterprises. Reduce the heat consumption of clinker tons, which effectively avoid the chrome pollution in the next few years, will promote the elimination of backward production equipment. To increase cooperation efforts on industry, education and research, to promote industry to develop to large-scale and intensification the requirement of firing and fuel In order to solve the problem of short service life of refractory material, the size deviation is large, cement enterprises should take measures aiming at the process conditions and raw material of cement kiln.

- Q: What kinds of annealing furnace refractory bricks there are?

- But the energy saving effect is good, but also can use lightwight heat insulating brick, but the price is higher than that of clay brick

- Q: does the electric kiln burner need to be sealed?

- seal when open the kiln, and observe the temperature, when the temperature reaches a point, you can move the firebrick away, and continue observing the temperature to decide whether to seal it or not, but do not seal it completely, repeat the procudure until reach the sinter point or skill requirement.

Send your message to us

Fireclay Brick - Low Porosity Hot Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords