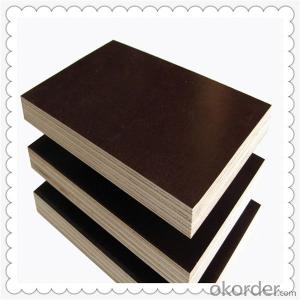

Composite Plywood Film Faced Brown Okplex Fresh Poplar Core WBP 4'x8'x18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 57.87

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Film Faced Plywood is a kind of plywood which inside plywood assembled of veneers and cross band glue impregnated veneers, and outside face veneer on either side topped with glue impregnated film. The glue is used differently like WBP, Phenolic Resin, etc. The veneer made of timber & wood such as Hard Wood, COMBI, Poplar, Birch, etc. Pack in encase in plates and laminated under very high pressure and heat. For the quality two times hot pressure is better than one time hot pressure.

Packaging & Delivery

(1).Packaging Detail: pallets package as standard shipment request.

(2).Delivery Detail: There are two options for customer.

(A).Stock from Jebel Ali Free Zone warehouse in Dubai, delivery available in one day after payment received.

(B).Booking from factories, delivery in 40 days after PI confirmed.

Specifications of Film Faced Plywood (Brand name: OKPLEX)

(1)Size: 1220 mm×2440 mm, 610 mm×2440mm, other special sizes.

(2)Thickness: 18mm, 12mm

(3)Core: Full fresh poplar.

(4)Glue: WBP

(5)Film: Brown

(6)Pressure: One time hot press.

(7)Moisture: 6%-9%.

(8)Thickness tolerance: +/-0.5mm.

(9)Duration time: can be 5/6 times used

(10)Usage: For normal project shuttering.

(11)Payment term: T/T or L/C at sight.

(12)Manufacture in China and Stock in Dubai,UAE

Advantage of Film Faced Plywood:

(1).Can be used not only one time, profitable as a property.

(2).High strength as wood product.

(3).Stability.

(4).Resilience.

(5).Superior Resistance.

(6).Smooth film faced as mirror.

(7).Flexible. plywood can be cut from one sheet to smaller specific size pieces.

- Q: Plywood in the material defects?

- resin leakage (resin) resin streak trees after the local injury, the resin gathered in a large number of them and through the surrounding wood and the formation of color than the surrounding normal wood deep

- Q: National standards for decorative veneer veneer plywood performance requirements

- The standard on the decorative veneer veneer plywood in the appearance of quality, processing accuracy, physical and mechanical properties of the three aspects of the indicators.

- Q: How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: What harm does the plywood factory work?

- Occupational acute benzene poisoning is the workers in the professional activities, short-term inhalation of high-dose benzene vapor caused by the central nervous system suppression as the main manifestation of systemic diseases

- Q: Material for the plywood defects which

- spotted flecks streaks system wood fungus invasion of wood early formation, often see brown. Tan or purple stains.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: Plywood in the processing of defects

- Separation delamination The separation of two adjacent veneers due to lack of glue or poor glue.

- Q: What are the types of veneer veneer veneer?

- Common is a single-sided veneer veneer plywood. Decorative veneer commonly used species of birch, ash, oak, water green Kong, elm, maple wood, walnut, etc.

Send your message to us

Composite Plywood Film Faced Brown Okplex Fresh Poplar Core WBP 4'x8'x18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 57.87

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords