Fiberglass Yarn for Tissue Manufacturing - e-glass Fiberglass Yarn

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

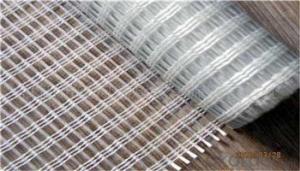

E-Glass Fiber Glass Yarn For Tissue Manufacturing is a kind of additional twisting and plying yam. With the characteristics of high strength, corrosion resistance, heat resistance and high moisture absorption, no-alkali yam has high electric insulation, so it used to produce weaved wires and cables’ wrap cladding, protection sleeve, train of mine, insulation materials of electric machinery, every yam of woven cloth and other industrial yam. It can also supply big and little paper cube and other cube yams with different shapes and different roll weight.

2.Product Features

Good Dispersibility.

Less fuzzy.

Density Even

3.Product Specifications

Product Code | Tex | diameter (um) | Sizing. | breaking strength | Twist |

CC7.5-22-1/2 110S | 44 | 7.5 | paraffin | ≥15.5 | 110±10 |

EC9-33-1/2 65S | 66 | 9 | ≥24.1 | 65±5 | |

EC8-25-1/2 65S | 50 | 8 | ≥19.2 | 65±5 | |

CC9-33-1/2 65S | 33 | 9 | ≥20.6 | 65±5 | |

CC11-44-6/0 | 264 | 11 | ≥81.6 | ||

CC11-44-1/3 110S | 132 | 11 | silane | ≥40.8 | 28±3 |

EC9-68-1/0 28Z | 68 | 9 | ≥18.0 | 28±3 |

4.FAQ

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

Empty Bobbins Returning:

The bobbins need to be returned and the buyer shall send bobbins to destination port and bear the related charge one they can filled in a full 40HQ.The seller shall handle the sea fright from destination port to China port.Customer should pay some deposite for the empty bobbins and the deposite can be treated as the payment for the future orders after the bobbins are sent back to the seller.

- Q: What is the melting point of fiberglass yarn?

- The melting point of fiberglass yarn can vary depending on its composition and manufacturing process. Generally, fiberglass yarn is made from glass fibers that have been melted and drawn into fine strands. These strands are then twisted or plied together to form a yarn. The melting point of the glass fibers used in fiberglass yarn is typically around 1,400 to 1,600 degrees Celsius (2,552 to 2,912 degrees Fahrenheit). However, it is important to note that the melting point of the yarn itself may be lower than the melting point of the individual fibers, as the twisting or plying process can affect the overall thermal properties of the material. It is also worth mentioning that while fiberglass yarn has a high melting point, it can still experience degradation or damage at lower temperatures. For example, prolonged exposure to temperatures above 200 degrees Celsius (392 degrees Fahrenheit) can cause the yarn to lose its strength and structural integrity. Therefore, it is crucial to consider the specific application and temperature requirements when working with fiberglass yarn to ensure its optimal performance and longevity.

- Q: What are the different thicknesses available for fiberglass yarn fabrics?

- Different applications and needs can be accommodated with various thicknesses of fiberglass yarn fabrics. Typically, lightweight to heavy-duty options are available. To meet the needs of lighter applications or those requiring more flexibility, thinner fiberglass yarn fabrics are suitable. These fabrics are lightweight and flexible, making them ideal for insulation, electrical insulation, or reinforcement in composites. For more demanding or heavy-duty applications, thicker fiberglass yarn fabrics are available. These fabrics are stronger and more rigid, making them suitable for reinforcement in structural composites, thermal insulation in high-temperature environments, or as a barrier against heat, fire, or chemicals. The specific thicknesses of fiberglass yarn fabrics may vary depending on the manufacturer or supplier. Lightweight fabrics usually range from 0.1 mm to 0.5 mm, while thicker fabrics can be 0.5 mm to 2 mm or more. When selecting the appropriate thickness of fiberglass yarn fabric, it is important to consider the intended application and performance requirements. Consulting with manufacturers or suppliers can help identify the most suitable thickness option for specific needs.

- Q: Can fiberglass yarn be used in the production of electrical tapes?

- Fiberglass yarn, with its high thermal resistance and electrical insulation properties, is a suitable material for the production of electrical tapes. By incorporating fiberglass yarn into the tape, it adds reinforcement, strength, and durability, making the tape resistant to high temperatures, electrical currents, and mechanical stress. Furthermore, the inclusion of fiberglass yarn improves the tape's dielectric properties, thereby enhancing its electrical insulation capabilities. As a result, fiberglass yarn is widely utilized in the manufacturing of electrical tapes.

- Q: How does fiberglass yarn perform in terms of durability?

- Fiberglass yarn is highly durable and known for its strength and resilience. It has excellent resistance to harsh weather conditions, chemicals, and UV rays, making it suitable for a wide range of applications. Additionally, fiberglass yarn is resistant to rot, mold, and mildew, further enhancing its durability.

- Q: Can fiberglass yarn be used in electrical cables?

- Yes, fiberglass yarn can be used in electrical cables. Fiberglass yarn is known for its high strength, durability, and resistance to heat and fire. These properties make it suitable for use in electrical cables where it can provide insulation and reinforcement. Fiberglass yarn is often used as a component in the manufacturing of high-temperature cables, such as those used in aerospace, automotive, and industrial applications, where the cables are exposed to extreme temperatures and need to maintain their integrity. Additionally, the non-conductive nature of fiberglass yarn ensures that it does not interfere with the electrical conductivity of the cables. Overall, fiberglass yarn can be a reliable and efficient choice for incorporating into electrical cables.

- Q: Can fiberglass yarn be used in reinforcement of polymer composites?

- Yes, fiberglass yarn can be used in the reinforcement of polymer composites. Fiberglass yarn is a commonly used material due to its high strength, lightweight nature, and resistance to corrosion. It is often used as a reinforcement material in polymer composites to enhance their mechanical properties and durability.

- Q: Is fiberglass yarn suitable for use in aerospace structures?

- Fiberglass yarn is indeed appropriate for utilization in aerospace structures. Being both lightweight and robust, fiberglass proves ideal for aerospace industry applications that prioritize weight reduction. It boasts high tensile strength, exceptional heat resistance, and commendable electrical insulation properties. Woven into fabrics or employed as reinforcements in composite materials, fiberglass yarn confers structural integrity and durability to aerospace structures. Moreover, its corrosion resistance is of great significance for aircraft and spacecraft subjected to challenging environmental conditions. All in all, fiberglass yarn stands as a dependable and extensively employed material in aerospace structures, owing to its desirable properties and performance characteristics.

- Q: Can fiberglass yarn be used for making shower curtains?

- Yes, fiberglass yarn can be used for making shower curtains. Fiberglass is commonly used in the textile industry due to its durability, water resistance, and mold/mildew resistance, making it an ideal material for shower curtains.

- Q: Is fiberglass yarn suitable for outdoor use?

- Yes, fiberglass yarn is suitable for outdoor use. It is known for its durability, resistance to harsh weather conditions, and ability to withstand UV rays. It is commonly used in outdoor applications such as in the construction of awnings, outdoor furniture, and other outdoor textiles.

- Q: Is fiberglass yarn suitable for use in automotive composites?

- Yes, fiberglass yarn is suitable for use in automotive composites. It is a commonly used material due to its high strength-to-weight ratio, excellent resistance to chemicals and temperature, and its ability to be easily molded into different shapes. Fiberglass composites provide structural support and enhance the overall performance and durability of automotive components.

Send your message to us

Fiberglass Yarn for Tissue Manufacturing - e-glass Fiberglass Yarn

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords