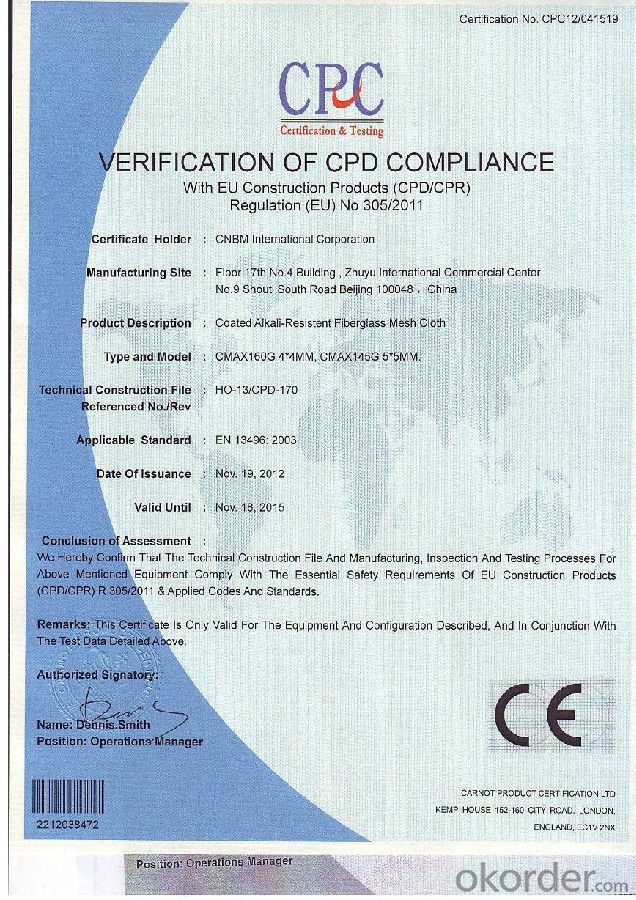

Fiberglass Mesh for Concrete Reinforcement - White Mesh, Wall Strength, Passed CE Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

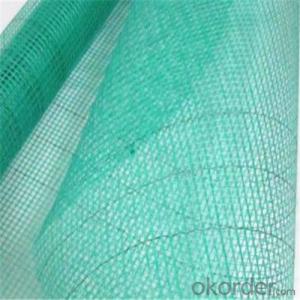

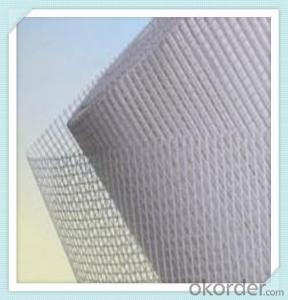

Quick Details of White Mesh, Wall strength, Passed CE Certificate

MOQ of White Mesh, Wall strength, Passed CE Certificate: 10000 Square Meters

Supply Ability of White Mesh, Wall strength, Passed CE Certificate: 6000000 Square Meters per Month

Payment Terms of White Mesh, Wall strength, Passed CE Certificate: L/C,T/T

White Mesh, Wall strength, Passed CE Certificate

Specifications of White Mesh, Wall strength, Passed CE Certificate

White Mesh, Wall strength, Passed CE Certificate Place of Origin: China (Mainland)

White Mesh, Wall strength, Passed CE CertificateBrand Name: CMAX

White Mesh, Wall strength, Passed CE Certificate Application: Wall Materials

White Mesh, Wall strength, Passed CE Certificate Width: 1M-2M

White Mesh, Wall strength, Passed CE Certificate Size: 5*5/ INCH

White Mesh, Wall strength, Passed CE Certificate Weight: 40gsm to 200gsm

White Mesh, Wall strength, Passed CE Certificate Weave Type: Plain Woven

White Mesh, Wall strength, Passed CE Certificate Yarn Type: C-Glass

White Mesh, Wall strength, Passed CE CertificateAlkali Content: Medium

White Mesh, Wall strength, Passed CE Certificate Standing Temperature: 500℃

Product information of White Mesh, Wall strength, Passed CE Certificate

Name: White Mesh, Wall strength, Passed CE Certificate

Use best fiberglass yarn and best glue

Clear and beautiful White Mesh, Wall strength, Passed CE Certificate

High strength White Mesh, Wall strength, Passed CE Certificate

30 years experience of manufacturing White Mesh, Wall strength, Passed CE Certificate

Excellent Priced White Mesh, Wall strength, Passed CE Certificate

FAQ of White Mesh, Wall strength, Passed CE Certificate

Q: What is White Mesh, Wall strength, Passed CE Certificate?

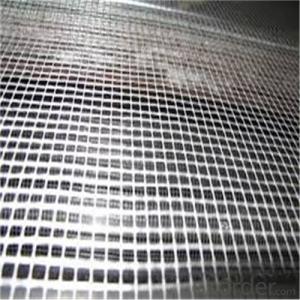

Coated Alkali-resistant White Mesh, Wall strength, Passed CE Certificate is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of White Mesh, Wall strength, Passed CE Certificate?

Weight: 135g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of White Mesh, Wall strength, Passed CE Certificate?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of White Mesh, Wall strength, Passed CE Certificate?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of White Mesh, Wall strength, Passed CE Certificate?

Four years under normal weather conditions and use .

Q: What is the package of White Mesh, Wall strength, Passed CE Certificate?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of White Mesh, Wall strength, Passed CE Certificate?

Production periods: 30days for 1X40HQ.

- Q: Can wall bricks be pasted on the indoor glass fiber gridding cloth?

- Marble, glass fiber gridding cloth is used for roofing waterproofing and wall or board reinforcement such as gypsum and mosaics.

- Q: Is glass fiber gridding cloth or finer wire mesh used before painting walls? What's the difference between them?

- If the cracks are too more, them gridding cloth is better to paste and batch apply putty. Or common bonding is ok. However, steel wire mesh is not to use hen batch applying putty. Moreover, if leveling cement mortar, then steel wire mesh can be used.

- Q: Is glass fiber gauze gridding cloth?

- Fiberglass gridding, with the full name of fiber glass gridding cloth, can be divided into alkali-resistant, middle-alkali, low-alkali gridding cloth according to the content of zirconium dioxide. The specifications are divided according to thickness (i.e., the thickness of fiberglass wire)

- Q: During the civil engineering, lintel and the red?brick are to prevent cracking, and whether it is good to use the mesh or the wire entanglement.

- the structure like this should be brick structure, I suggest using the steel mesh, and mesh should be wrapped the corner or used on the external wall

- Q: what's the specification of the external wall thermal insulation mesh?

- The mesh of interior wall is made of glass fiber as the main raw material and the tensile strength resistance is better when used in the exterior wall, and the number of applied grams is not the same, but it is also made through the process of multi-channel, the external wall thermal insulation mesh is generally 80-160 g, quality anti-tensile strength is relatively small, usually about 50-60 grams. the unit weight of interior wall thermal insulation mesh will be generally lighter. The interior wall of this mesh is the ideal material of grc wallboard.

- Q: What are the raw materials of mesh?

- They are nylon, flax, acrylic fibers, dacron and cotton.

- Q: Rock wool board insulation, why add two layers of glass fiber network, and XPS is a layer?

- Rock wool with two layers of mesh cloth and not improve crack resistance, but because wool soft texture, installing the anchor bolt after the surface is uneven, with two layers of mesh is to increase the thickness of the mortar, to find the plane. There is no such phenomenon in the extrusion board.

- Q: What is the difference between carbon fiber and glass fiber

- Glass fiber (formerly known as English: glass fiber or fiberglass) is a kind of excellent inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance.

- Q: What is the function of epoxy resin mesh

- it is mainly used for the casting transformer and electric reactor, soaking in the epoxy resin, and the mesh of H level epoxy glass is using the alkali-free glass fiber with high insulation grade, no partly emission and no bubble in the interior. The product is impregnated throughly in the epoxy resin, solidified and sizinged by drying, and the terylene interweaving to the square opening gridding and the gray cloth is dehydrated by high temperature.

- Q: If external insulation material is insulation putty, is it necessary to wrap external corners of mesh?

- Before being paving, mesh shoule be scraped a leveling blamket with cracking resistant mortar on insulation layer. Then paste mesh, slightly press it with trowel, and scrape another cracking resistant mortar to make sure that mesh is outside of the cracking resistant mortar so that it is crack-resistant.

Send your message to us

Fiberglass Mesh for Concrete Reinforcement - White Mesh, Wall Strength, Passed CE Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords