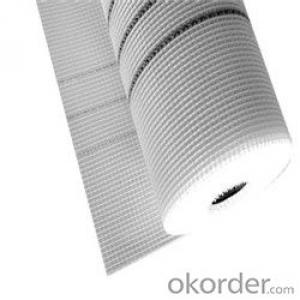

Fiberglass Mesh Cloth 160g 1*50m - High Quality Reinforcement Material

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

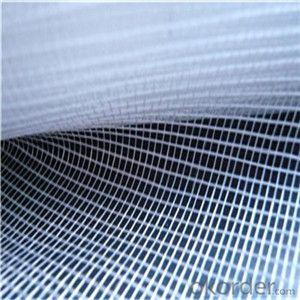

Coated Alkali-resistant fiberglass mesh cloth isbased on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface.The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave.

The diameter of elementary fiberglassvaries between 9 and 15 micron.The resin used for the surface treatment ensures the property of alkali-resistance and increases the mechanical durability that is required by the construction industry.

Fiberglass Mesh Cloth

is mainly alkali-resistant fiberglass fabric, it made of the C or E glass fiber yarn (main ingredient is a silicate,

good chemical stability) through a special weaving technique, then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing. It’s ideal engineering material in construction and decoration industry!

Fiberglass Mesh Cloth Main characteristics:

1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemical corrosion resistant, and strong resin bonding, soluble in styrene.

2.Outstanding process :Include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after 28-day immersion of 5% Na(OH) solution, so that guarantee high strength, high tensility, light weight.

3.Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it own 20% extra strength and beauty surface than normal fiberglass yarn!

4.Strength retention rate > 90%, elongation <1%, the durability of more than 50 years

5.Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property..

6.Good impact resistance and not easy to be teared.

7.Fire resistant, thermal insulation, sound insulation, insulations etc.

Fiberglass Mesh Cloth Application:

1.Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board,gypsum board, bitumen etc)

2.Reinforced cement products.

3.Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

5.Framework material for reinforced plastics, rubber products,.

6.Fire board

7.Grinding wheel base fabric.

8.Road surface with geogrid

9.Construction caulking tape etc.

Fiberglass Mesh Cloth Specifications:

1.16x16 mesh, 15x14 mesh, 12x12 mesh, 10x10 mesh, 9x9 mesh, 8x8 mesh, 6x6 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 3x3 mesh, 2.5x2.5 mesh, 1x1 mesh and so on

2.Weight/sq.meter: 40g—800g

3.Each roll length: 10m,20m,30m,50m—300m

4.Width: 1m—2.2m

5.Color: White (standard) blue, green, orange, yellow and others.

6.We can produce many specifications and use different packaging according to customers’ requests.

- Q: How is fiberglass mesh used?

- Brushing the wall latex Putie mesh cloth, mesh cloth to Putie formation, Jiecha overlap should be at least 50MM, to be completely dry after the wall, and then carry out the procedure.

- Q: What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- The reason: the current domestic weaving factory method or pre roll beam weaving, and net fabric warp yarn and weft yarn is usually, roving, the intensity is greater than the warp weft. Secondly, to weave is usually weaving, woven to the continued strength of more than.

- Q: Where is fiberglass mesh better?

- However, the import of fiberglass mesh cloth obviously higher prices. If more stringent cost control, can not consider the domestic crude Taishan glass fiber mesh cloth, glass fiber or wellav.

- Q: Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- The two layer and the above position can not be reached by human activities, so it is OK to adopt single layer mesh cloth.

- Q: Glass fiber mesh cloth bent do to straighten it?

- Can be divided into gold pot and earthen pot, the general earthen pot product soft and hard to control, because the surface of the pot products are generally coated with urine glue, gold pan surface coated with emulsion, quality is good, control some. Soil pot products only two kinds of hard and soft state, one is hard, then the product is slightly, but the texture is brittle, the tensile resistance is not good, it is easy to break ninety percent off, a state is soft, this product is pulling resistance is large, but not so on the location, soil pot coated urine glue products, soft and positioning the product is contradictory, hard, good positioning effect, small tensile strength, soft, poor positioning effect, large force.

- Q: Can fiberglass mesh waste be recycled? What can you do if you can?

- Glass fiber mesh cloth is flame retardant products, the core material is glass fiber yarn production is completed, so has the recovery effect, which is proved that the glass fiber environmental protection that, during the two days trip I found some problems, the mesh is scrap cut, some are everywhere a throw, some is burned, there is a direct classification.

- Q: What harm does fiberglass mesh have to people?

- Inhalation of respiratory tract causing lung damage. Three

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The external wall insulation mesh (glass fiber mesh) with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into. The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q: What are the fiberglass mesh fabric manufacturers?

- Mesh cloth (heat preservation net)The mesh cloth is based on medium alkali or E-glass fiber woven fabric and is treated with alkali resistant coating. The product has high strength and good alkali resistance, and plays an important structural role in the thermal insulation system, mainly to prevent cracks. Due to its excellent acid, alkali and other chemical substances pedants performance and weft tensile strength is high, can make the wall stress of dispersed insulation system, can avoid the extrusion deformation, external force caused by the collision of the insulation structure, the insulation layer has high impact resistance strength, and easy to construction and quality control, to "soft steel" role in the insulation system.

- Q: What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- Method of setting quotas:1.. What project quantity sets what quota, first find the amount of project quantity that needs to be set.2. understand the base price. The price is fixed in artificial materials machinery (+ +, it is note that units) are now consumption quota, consumption is the loss of quota book has made it clear that each of the different material loss, this loss is fixed price price * material.

Send your message to us

Fiberglass Mesh Cloth 160g 1*50m - High Quality Reinforcement Material

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords