Fiberglass Mesh Cloth with Plain/Lenox Woven Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Mesh AR Plain/Leno Woven Structure

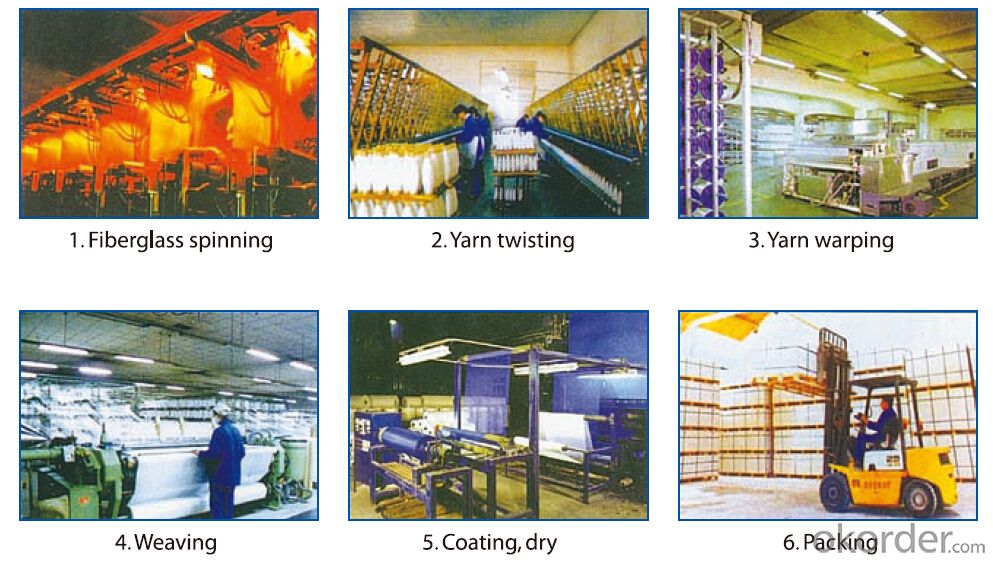

Fiberglass Mesh Instruction

Coated Alkali-resistant fiberglass mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface.

The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave.

The diameter of elementary fiberglass varies between 9 and 15 micron.

The resin used for the surface treatment ensures the property of alkali-resistance and increases the mechanical durability that is required by gthe construction industry.

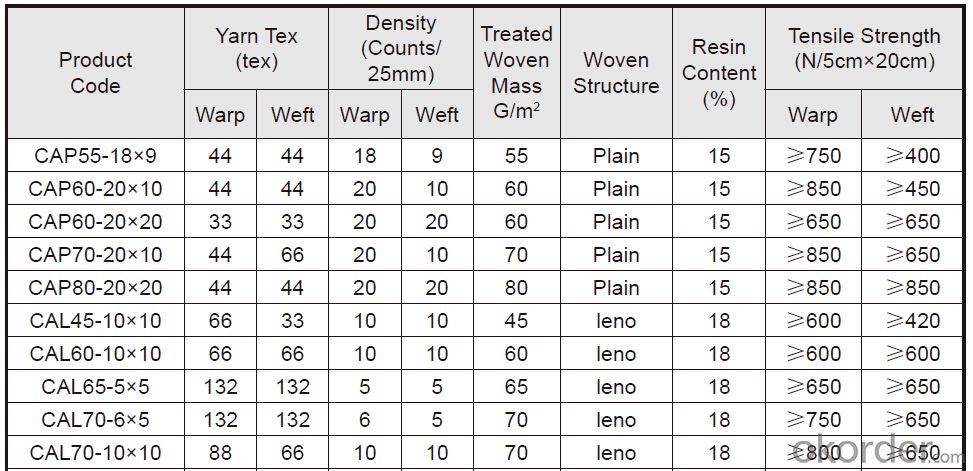

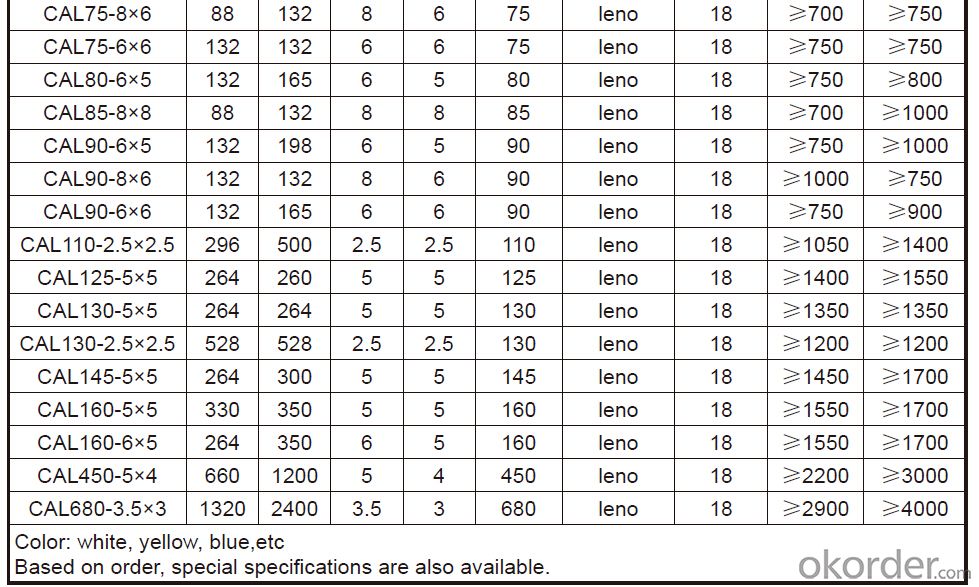

Fiberglass Mesh Specification

Fiberglass Mesh Features

1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

2. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

3. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

4. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

5. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

6. Good impact resistance and not easy to be teared.

Fiberglass Mesh Application

1.External thermo insulating composite system(ETICS)&External Insulating Finish System(EIFS)

2.External and internal plaster reinforcement

3.Electrical heating mats

4.Marble slab reinforcement.mosaic carrier

5.Asphalt reiforcement(roof water0proof)

6.Reinforced lightweight construction boards

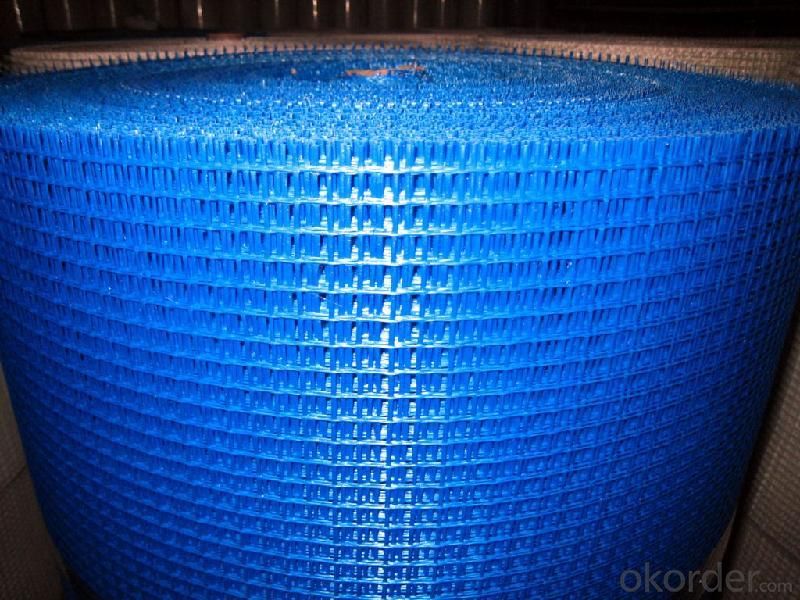

Product Show

FAQ

Q: What is the storage of Fiberglass Mesh?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh?

Four years under normal weather conditions and use .

Q: What is the package of Fiberglass Mesh?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Fiberglass Mesh?

Production periods: 30days for 1X40HQ.

- Q: How is fiberglass mesh used?

- The wall should be cleaned before paving and the pits will be patched and leveled

- Q: Where are the steel wire mesh and the alkali resistant grid cloth used in the exterior wall insulation?

- Two different wall plastering joints, to play a role in cracking; generally in the amount of graphics can be directly in the report to see the amount of engineering;Wire mesh and mesh cloth each have their own uses! Specific to see your design drawings.

- Q: Where is fiberglass mesh better?

- However, the import of fiberglass mesh cloth obviously higher prices. If more stringent cost control, can not consider the domestic crude Taishan glass fiber mesh cloth, glass fiber or wellav.

- Q: What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- Most of the fiberglass mesh is used for the powder, but also outside powder, but at present there is no domestic how expensive, too expensive!

- Q: Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- The two layer and the above position can not be reached by human activities, so it is OK to adopt single layer mesh cloth.

- Q: Glass fiber mesh fabric quality, hard and soft for wall, which is better?

- Used on the wall, of course, is more good glue, can increase the degree of alkali resistance. Now there's one kind of urine gum, it's really hard to paint. But there is no alkali resistance.

- Q: What is the function of the wall cloth mesh?

- Wall mesh, also called glass fiber wall mesh, with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- It would be to see how the strength of cement foam insulation board, and you paste the process in order to improve the strength, you can use 1 to 1 fiber cement mortar with latex mixing, can increase the thickness and strength, the cost will be reduced, it can in the brick veneer.

- Q: Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- This product and people engaged in the industry of external wall insulation pot imitation gold mesh fabric is very familiar, but exactly how this product is really not much here to explain imitation gold mesh pot is to be defined.

- Q: Slotted walls, seams, seams, tape, or anti mesh cloth?

- Don't spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay.

Send your message to us

Fiberglass Mesh Cloth with Plain/Lenox Woven Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords