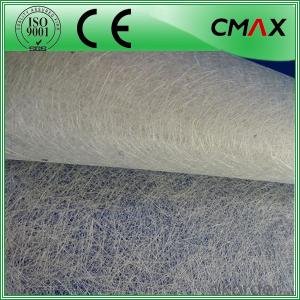

Fiberglass Chopped Strand Insulation Material Fiber Glass Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Surfacing Tissue mainly used in the surface layers of FRP products. It features even Fiber distribution, soft feel, level and smooth fiber surface, less glue content, quick resin soak and good pattern fitness. It can improve the product surface property on corrosion resistance, compressive strength, seepage resistance, and longer service life. It is also suitable for spraying; pattern pressing and other FRP pattern technology.

Surfacing Tissue mainly used in the surface layers of FRP products. It features even Fiber distribution, soft feel, level and smooth fiber surface, less glue content, quick resin soak and good pattern fitness. It can improve the product surface property on corrosion resistance, compressive strength, seepage resistance, and longer service life. It is also suitable for spraying; pattern pressing and other FRP pattern technology.

Product Features:

Fast breakdown in styrene

Fiber dispersed evenly

Low binder content

Superior acid corrosion resistance

Specifications:

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

Product Packaging:

Each Surface Tissue is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 330mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Product Storage:

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 50%~75% respectively.

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

- Q: Can fiberglass chopped strand be used in marine applications?

- Yes, fiberglass chopped strand can be used in marine applications. It is commonly used in boatbuilding and other marine structures due to its excellent strength, durability, and resistance to water and corrosion.

- Q: What are the chemical insulation properties of fiberglass chopped strand?

- Fiberglass chopped strand is a type of insulation material that possesses excellent chemical insulation properties. Due to its composition of glass fibers, it is highly resistant to the effects of many chemicals. Fiberglass chopped strand insulation has a high resistance to acids, alkalis, and solvents, making it a suitable choice for applications where exposure to these substances is expected. The chemical insulation properties of fiberglass chopped strand can be attributed to the inherent properties of glass fibers themselves. Glass is a non-reactive material, meaning it does not readily interact with most chemicals, making it a reliable insulator. The glass fibers in fiberglass chopped strand form a dense and closely-knit network, creating a barrier that prevents the penetration of chemicals. Furthermore, the use of a resin matrix in fiberglass chopped strand insulation provides an additional layer of protection against chemical exposure. The resin acts as a binder, holding the glass fibers together and enhancing their resistance to chemical attack. This combination of glass fibers and resin matrix makes fiberglass chopped strand insulation highly effective in insulating against a wide range of chemical substances. In addition to its chemical insulation properties, fiberglass chopped strand insulation also offers other benefits. It is lightweight, easy to install, and has excellent thermal insulation properties. It is also non-combustible, making it a safe choice for applications where fire resistance is required. Overall, fiberglass chopped strand insulation is an ideal material for chemical insulation applications due to its high resistance to acids, alkalis, and solvents. Its non-reactive nature and the use of a resin matrix provide reliable protection against chemical exposure.

- Q: What are the acoustic insulation properties of fiberglass chopped strand?

- Due to its unique composition and structure, fiberglass chopped strand possesses exceptional acoustic insulation properties. Comprised of fine glass fibers that are randomly arranged and bound together with a resin or binder, the chopped strands form a dense and fibrous structure that effectively absorbs sound waves. The main way in which fiberglass chopped strand provides acoustic insulation is by diminishing sound transmission. When sound waves collide with the surface of the fiberglass, they are converted into mechanical vibrations, which are then absorbed and dispersed within the fibrous structure. Through this absorption process, the material significantly reduces the amount of sound that passes through it, resulting in a quieter environment. Moreover, the dense and fibrous nature of fiberglass chopped strand helps to dampen and lessen sound. The numerous air pockets and interlocking fibers within the material create a high level of internal friction, which effectively dissipates sound energy. This not only reduces the intensity of sound but also helps to prevent the transmission of vibrations and resonance. Furthermore, fiberglass chopped strand is renowned for its outstanding thermal insulation properties, which indirectly contribute to acoustic insulation. The material's ability to resist heat transfer helps maintain a consistent temperature, thereby reducing the occurrence of sound-reflecting surfaces and minimizing the amplification of noise. In conclusion, fiberglass chopped strand is an exceptionally efficient material for acoustic insulation. Its dense and fibrous structure, combined with its capacity to absorb, dampen, and attenuate sound waves, make it an ideal choice for applications requiring noise reduction and control, such as in construction, automotive, and industrial settings.

- Q: Uses, specifications and functions of the Geogrid.

- Geogrid is a major geosynthetics. Compared with other geosynthetics, it has a unique performance and effectiveness. Geogrid is usually used as the reinforced soil structure tendon material or composite material geosynthetics. The geogrid is divided into plastic geogrid, steel plastic geogrid, glass fiber geogrid and fiberglass polyester geogrid. (1) The plastic geogrid is Polymer netting materials with a square or rectangular shape after pultrusion. According to the direction of pultrusion, it can be divided into uniaxial?tension and two-way stretch. It is punched in the polymer sheet material (raw material is polypropylene or high density polyethylene) after pultrusion, and then operate orientation stretching in heating codition. The aniaxial tension geogrids is made only along the length direction of the sheet, while the two-way stretching gridgeogrids is made by pultrusion the aniaxial tension geogrids along the direction which is vertical to the length.

- Q: Can fiberglass chopped strand be used in the production of wind turbine towers?

- Yes, fiberglass chopped strand can be used in the production of wind turbine towers. It is commonly used as a reinforcement material in the manufacturing of composite structures, providing strength, durability, and corrosion resistance. The fiberglass chopped strand is typically mixed with a resin matrix to form composite panels or laminates, which are then used to construct the wind turbine towers.

- Q: Is fiberglass chopped strand suitable for use in corrosive environments?

- No, fiberglass chopped strand is not suitable for use in corrosive environments as it is prone to degradation and damage when exposed to corrosive substances.

- Q: Can fiberglass chopped strand be used for sound insulation?

- Yes, fiberglass chopped strand can be used for sound insulation. Fiberglass is a commonly used material for soundproofing due to its excellent sound absorption properties. When installed correctly, fiberglass chopped strand can help reduce noise transmission and improve acoustic insulation in buildings. It can be used in various applications such as walls, ceilings, floors, and HVAC systems to dampen sound and create a quieter environment. Additionally, fiberglass chopped strand is lightweight, flexible, and easy to install, making it a popular choice for sound insulation projects.

- Q: Can fiberglass chopped strand be used in pipe manufacturing?

- Indeed, the utilization of fiberglass chopped strand is feasible in the production of pipes. This particular material, fiberglass chopped strand, possesses a wide range of applications, one of which is pipe manufacturing. It boasts numerous benefits, such as its exceptional strength, resistance to corrosion, and lightweight characteristics. By combining the chopped strands with resin and employing various manufacturing techniques like filament winding or pultrusion, it becomes possible to shape the material into a pipe form. Consequently, the resulting fiberglass pipe exhibits outstanding mechanical properties, including remarkable tensile strength and stiffness, as well as resistance to both chemicals and extreme temperatures. Furthermore, fiberglass pipes are renowned for their durability and minimal maintenance requirements, making them a favored choice in industries such as oil and gas, chemical processing, and wastewater treatment.

- Q: Can fiberglass chopped strand be used for reinforcing foam materials?

- Yes, fiberglass chopped strand can be used for reinforcing foam materials. The chopped strands can be mixed with foam materials to enhance their strength, durability, and resistance to deformation.

- Q: What are the typical cost considerations when using fiberglass chopped strand composites?

- When using fiberglass chopped strand composites, there are several typical cost considerations to be taken into account. Firstly, the cost of the raw materials themselves, including the fiberglass strands and the resin used to bind them together, will affect the overall cost. The quality and specifications of these materials can vary, leading to different price points. Another cost consideration is the manufacturing process. The method used to produce fiberglass chopped strand composites can vary, and each technique may have different associated costs. For example, hand lay-up or spray-up methods may be less expensive than more advanced techniques like resin infusion or filament winding. Labor costs also play a significant role in the overall cost. The skills required to work with fiberglass chopped strand composites, including cutting, shaping, and laminating the material, can affect the labor expenses. Skilled workers may demand higher wages, while less experienced labor can lead to increased production time and potential quality issues. Furthermore, the complexity and size of the final product will impact the cost. Larger and more intricate components will require more raw materials, labor, and time to manufacture, resulting in higher costs. Additionally, any additional finishing processes, such as painting or coating, may contribute to the overall expenses. Transportation and logistics costs should also be considered when using fiberglass chopped strand composites. Depending on the location of the manufacturing facility and the destination of the finished product, shipping expenses can vary significantly. Oversized or fragile components may require specialized handling and packaging, further increasing transportation costs. Lastly, it is important to consider the total lifecycle cost of fiberglass chopped strand composites. Although the initial investment may be higher compared to other materials, fiberglass composites offer advantages such as durability, corrosion resistance, and lightweight properties. These factors can lead to long-term cost savings by reducing maintenance, repair, and replacement expenses. Overall, the typical cost considerations when using fiberglass chopped strand composites include raw material costs, manufacturing process, labor expenses, product complexity, transportation, and long-term lifecycle costs. Understanding these factors will help in accurately estimating the overall cost of using fiberglass chopped strand composites for various applications.

Send your message to us

Fiberglass Chopped Strand Insulation Material Fiber Glass Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords