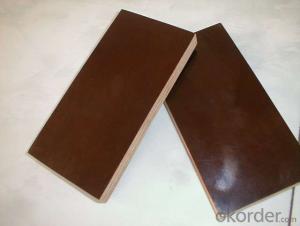

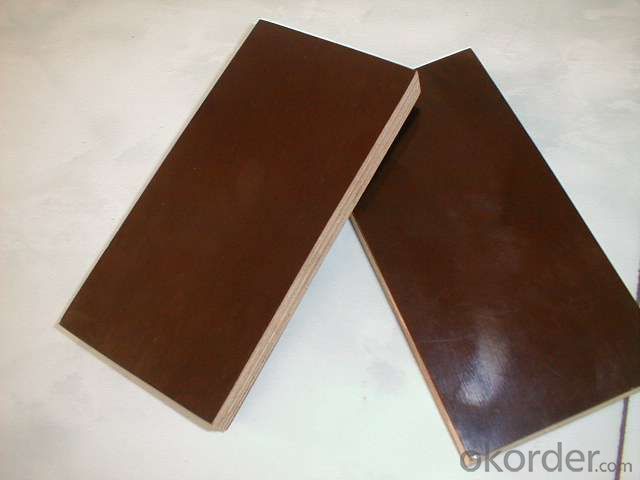

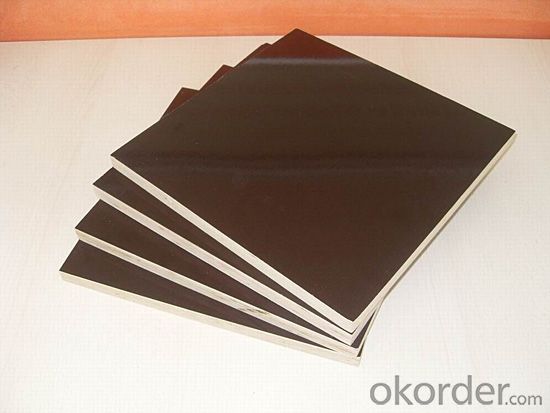

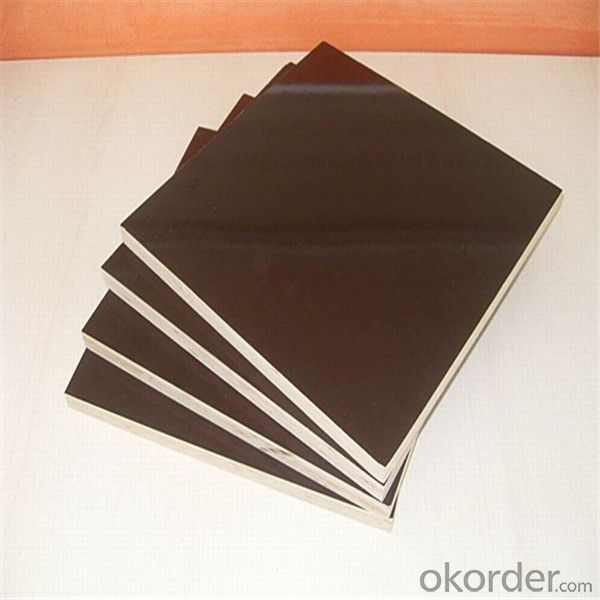

Factory Supply Fire Rated Film Faced Marine Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION

| Type: | Plywoods | Place of Origin: | China (Mainland) | Brand Name: | cnbm |

| Model Number: | 1220mm*2440mm &1250mm*2500mm or as your demand | Usage: | Outdoor | Grade: | First-Class |

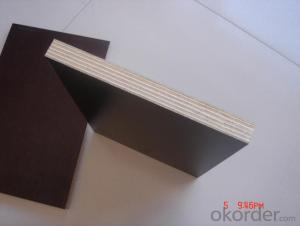

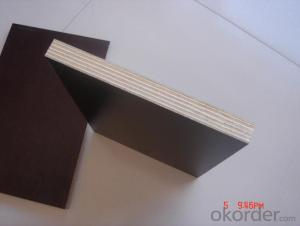

| Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | 12-Ply Boards |

FEATURE

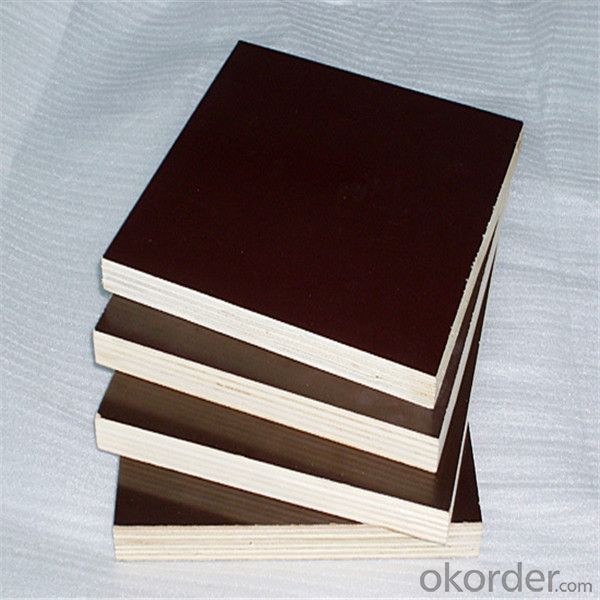

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they

are very light, so Chanta film faced plywood is convenient for transporting, and only one per-

son could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork co-

uld be cut into the required size.

3. Re-used: film faced plywood could be used 8-10 times.

4.Multi Using: could be used for wall, slab, column, beam and bri-

dge concrete pouring etc..

5. No Deformation: film faced plywood is also whole but not deformation and chipp-

ing after 72 hours cooking in boiling water.

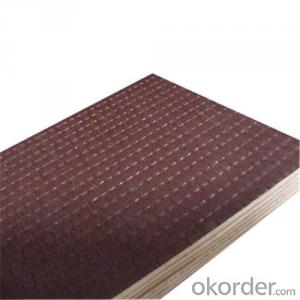

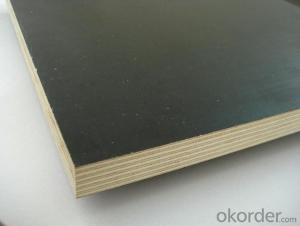

6. High Quality Film: film faced plywood is filmed by Dynea brown or black film impor-

ted from Finland, it protect the formwork surface from the corrosion and makes the formwo-

rk durable, improves the flatness of the concrete surface and makes the concrete surface save

the second time plastering, so it could save a lot cost of construction.

SPECIFICATION

Dimension(mm) | a> 1220*2440*9–25 mm b> 1250*2500*9-25 mm | |

Film | Chinese black/brown, Imported brown | |

Core | Poplar, Hardwood, Combi etc | |

Glue | MR, Melamine, WBP | |

Grade | AA | |

Moisture Content | 6-14% | |

Tolerance | Length&Width:+/-0.3mm | |

Thickness:+/-0.5mm | ||

Density | >550~650 kG/CBM | |

Modulus of rupture | >30Mpa | |

Modulus of Elasticity | >6000Mpa | |

Certification | ISO9001:2000 ISO14001:2004 OHSAS18001:1999 | |

Usage | Usage adequate for making furniture or construction, packing or industrial | |

Payment Terms | T/T or L/C at sight | |

Min Order | 1*40HQ container | |

Quantity | 20GP | 8 pallets |

40GP | 16 pallets | |

40HQ | 18 pallets | |

Delivery Time | About 30 days after receiving deposit T/T or L/C at sight | |

Advantages:

| 1) Light weight: better be used for high building and bridge consreuction 2) Large extent: the largest extent is 1250*2500mm, reduce the juncture in order to improve the work efficiency 3) No warp, no distortion, no cleft, well water-resistant, long-playing used and recycled 4) Do concrete: beautiful and slippy surface | |

- Q: Now what is the market for plywood development?

- the cumulative sales revenue was RMB 72,163,513,000, an increase of 39.25% over the same period in 2005; total accumulated profit 3,198,494,000 Yuan, compared with the same period in 2005 increased by 60.41%.

- Q: What is the type of plywood editing?

- the plywood is divided into decorative plywood (for the surface needs to paint transparent paint Furniture, sewing machines and all kinds of electrical appliances and other products)

- Q: Wood board, plywood, MDF What is the difference

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q: The Preparation of plywood ingredients

- core core core sandwich panel or composite plywood center layer. Usually its thickness is greater than the other layers.

- Q: What is a joinery board?

- The center plate of the blockboard should have the same direction of grain and perpendicular to the texture of the core.

- Q: Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Plywood should be shipped with the factory quality inspection department of product quality certification, specify the type of plywood, specifications, grade, bonding strength and moisture content.

- Q: What is the plywood made of wood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: What are the shortcomings of plywood

- the plywood is not as smooth as the density of the board, with the plywood to do the grassroots, the surface and then bonding fire board, aluminum panels and other decorative panels, as the density board to do solid base

- Q: The usual length and width specifications are:

- 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on.

Send your message to us

Factory Supply Fire Rated Film Faced Marine Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords