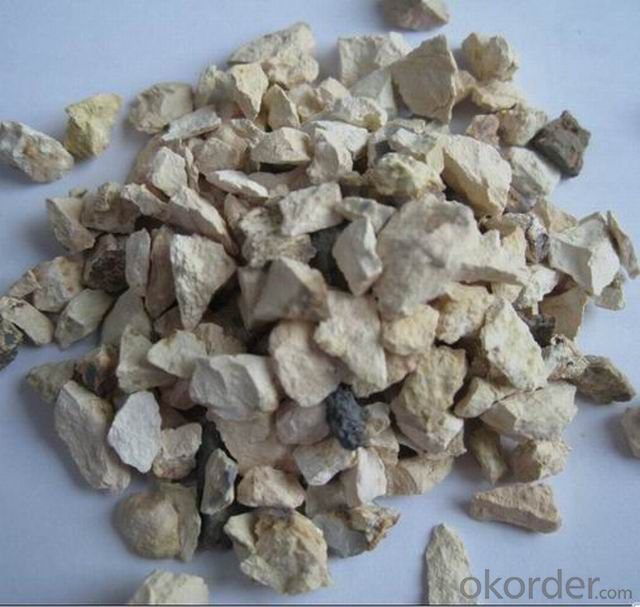

Raw Materials for Refractory:Factory Direct Supply Rotary Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | ≤0.2 | Al2O3 Content (%): | ≥99 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° |

| Model Number: | TY-AKZ-99 | Brand Name: | CN | Size: | Any size |

Packaging & Delivery

| Packaging Details: | Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips |

| Delivery Detail: | 2 months |

Specifications

Applications:

1.Lining of high temperature furnace

2.Thermal insulate of ultra-high temperature furnace

Physical and chemical index

Item | AKZ-85 | AKZ-90 | AKZ-99 | |

Chemical composition | Al2O3 | ≥85 | ≥90 | ≥99 |

SiO2 | ≤13 | ≤8 | ≤0.2 | |

Fe2O3 | ≤0.5 | ≤0.5 | ≤0.5 | |

Apparent Porosity% | 58-62 | 58-62 | 58-62 | |

Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 | |

Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 | |

0.1Mpa Refractoriness Under Load T0.6 °C | ≥1650 | ≥1700 | ≥1700 | |

Permanent Linear Change On Reheating (%)1500°CX2h | ±0.3 | ±0.3 | ±0.3 | |

20-1300°C Thermal Expansion % (x 10-6) | 0-7.8 | 0-8.0 | 0-8.6 | |

Thermal Conductivity(Average 800°C) W/(M.K) | ≤0.8 | ≤1.3 | ≤1.5 | |

Max Service Temperature °C | 1680 | 1700 | 1800 | |

- Q: What are some of the new refractories and what are their characteristics?

- Refractory common AZS refractories are often used brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, aluminum oxide, beryllium oxide and other refractory materials, Magnesium Oxide

- Q: Who knows the setting requirements of roofing fire barrier zone?

- First, the the minimum of fire barrier width is greater than 30cm, and the thickness should be same to the thickness of the insulation materials. Fire barrier zone insulation board must do the whole area sticking construction with the base wall during the construction. Fire barrier zone insulation board is required to assistant binding by anchor bolt, anchor bolt must suppress the underlying mesh. Second, Fire barrier zone should be set at the upper position of door and window openings, the distance between the low edge of isolation belt and the upper edge of the window must be less than 50cm. The thermal resistance of fire barrier zone must be half than EIFS thermal resistance in the cold northern areas, while the thermal resistance of fire barrier zone must be three times than EIFS thermal resistance in the hot summer and cold winter area. Third, When the fire barrier zone is set on the edge of the window, fire barrier zone at the upper part of the window should do flanging when sticking, flanging glass fiber mesh must exceed 10CM than firebreak insulation board. Flanging network, underlying network and surface network can not be overlapped or butted at the top of the window. I hope you can be satisfied

- Q: How long is the fire resistant limit for ultra thin fire retardant coating?

- According to the "code for fire protection design of tall buildings", the fire resistance time of the component is at the first level: 3 hours, beam: 2 hours, floor: 1.5 hours;if fire resistance level is level 2, the requirement for time of fire resistance component is the column: 2.5 hours, beam: 1.5 hours, floor: 1 hours. For fire resistant coating, fire resistance time for ultra-thin fire retardant coating is less than 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be uesd.

- Q: how about the performance of aluminum silicate fire proof thermal insulation?

- aluminum silicate fire proof thermal insulation board has a good performance. it is a artificial board that separates the wood and plant fiber by mechanical and chemical methods and mixed the adhesion agent and water-proofing?agent, molding by high temperature and high press. MDF(medium density fibre board) structure is more even than natural wood. it avoids rot, moth-eaten and other problems, while medium density fiber board has small expansion and contraction, which is easy to be processed. Since the surface of medium density fibre board is smooth, the board is easy to paste a variety of finishings, which makes furniture more beautiful. A variety of decorative wood-based panel is to embellish their homes.

- Q: What are the refractory materials above 1000℃

- corundum would be fine

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- Refractories in this industry, Luoyang Hua Heng is the first to bear, and their services are thoughtful, and the quality is still very good!Wish you success!

- Q: How to divided the grade of external wall thermal insulation materials?

- 1, According to China's national standard GB8624-97, combustion performance of building materials will be divided into the following grade level A: Incombustible building material: It is a kind of material that almost does not occur burning. Level B1: Nonflammable building material: Non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Level B2: Combustible?building?materials: Flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs. Level B3: Combustible?building?materials: It has no any flame resisting effects, and is easy to burn, so the fire risk is high. 2, The external wall thermal insulation materials is divided by fire rating 1) level A combustion performance thermal insulation material Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope my amswers are helpful to you

- Q: How to measure the influence of high-temperature performance of the products refractory in the formation of the liquid phase.

- Generally how can do high-temperature performance to measure how much liquid may affect hot bending strength rul refractoriness levels of high temperature creep?

- Q: The performance of refractory material

- The mechanical properties of refractory material include withstand voltage strength. The structure properties of the refractory materials include porosity, bulk density, such as thermal emission rate. The physical properties of the refractory materials include temperature conductivity structure performance, wear resistance, hiphotos, electrical conductivity, creep, the hydration resistance, adhesive strength.

- Q: Which region use more refractory?

- You can read some relevant statistical material and east China uses refractory the most.

Send your message to us

Raw Materials for Refractory:Factory Direct Supply Rotary Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords