Factory 12mm 16mm 20mm A400 Reinforcement Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

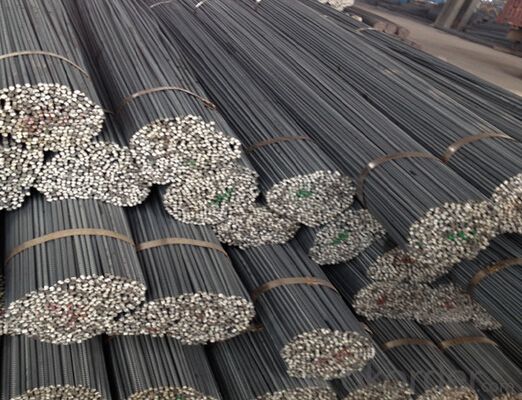

Factory 12mm 16mm 20mm A400 Reinforcement Steel Rebar

Details of the Factory 12mm 16mm 20mm A400 Reinforcement Steel Rebar

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the Factory 12mm 16mm 20mm A400 Reinforcement Steel Rebar

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the Factory 12mm 16mm 20mm A400 Reinforcement Steel Rebar

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the purpose of ribbed steel rebars?

- The purpose of ribbed steel rebars is to provide reinforcement and enhance the strength of concrete structures, such as buildings, bridges, and roads. The ribs on the rebar increase the bond between the steel and concrete, preventing slippage and improving the overall structural integrity.

- Q: What is the role of steel rebars in load-bearing structures?

- The role of steel rebars in load-bearing structures is to provide reinforcement and increase the overall strength and durability of the structure. Steel rebars are embedded within concrete to enhance its tensile strength, as concrete alone is weak in tension. By distributing and resisting the applied loads, rebars help prevent cracks and failures, ensuring the stability and longevity of the load-bearing structure.

- Q: Can steel rebars be used in the construction of offshore oil platforms?

- Yes, steel rebars can be used in the construction of offshore oil platforms. Steel rebars are commonly used in construction to reinforce concrete structures and provide additional strength and durability. In the case of offshore oil platforms, steel rebars are used to reinforce the concrete foundations and structures of the platform, helping to withstand the harsh environmental conditions and the weight of the equipment and infrastructure on the platform. The steel rebars are designed to resist corrosion and are typically coated with epoxy or other protective coatings to prevent rusting in the corrosive marine environment. Additionally, steel rebars can be custom-designed to meet the specific requirements of the offshore oil platform, ensuring they provide the necessary strength and stability.

- Q: Can steel rebars be used in industrial construction?

- Yes, steel rebars are commonly used in industrial construction. They provide strength, durability, and structural support to reinforced concrete structures, making them ideal for heavy-duty applications in industrial settings.

- Q: What are the weight and density of steel rebars?

- Steel rebars, also known as reinforcing bars, are commonly utilized in construction to impart tensile strength to concrete structures. The weight and density of steel rebars may differ depending on their size and grade. The weight of a steel rebar is determined by its cross-sectional area and the specific weight of steel, which is roughly 7850 kilograms per cubic meter (or 0.2836 pounds per cubic inch). The cross-sectional area is usually quantified in square millimeters or square inches. For instance, a prevalent size of steel rebar is the #4 bar, possessing a diameter of 12.7 millimeters (or 0.5 inches) and a cross-sectional area of 127 square millimeters (or 0.197 square inches). By employing the specific weight of steel, we can compute the weight of a #4 rebar in the following way: Weight = Cross-sectional area x Specific weight of steel Weight = 127 mm^2 x 7850 kg/m^3 Weight = 998,950 grams or approximately 998.95 kilograms (or 2,201 pounds) Concerning density, the density of steel rebars coincides with the specific weight of steel, which is roughly 7850 kilograms per cubic meter. This density remains relatively consistent across diverse sizes and grades of steel rebars. It is important to acknowledge that the weight and density of steel rebars may slightly fluctuate based on the precise composition and manufacturing process. It is therefore prudent to refer to the manufacturer's specifications or consult engineering references for precise and up-to-date information.

- Q: What is the role of steel rebars in preventing structural vibrations?

- The role of steel rebars in preventing structural vibrations is to provide reinforcement and increase the stiffness of concrete structures. Steel rebars are embedded within the concrete, forming a skeletal framework that enhances the structural integrity and reduces the risk of vibrations. When a load or force is applied to a structure, such as wind or seismic activity, it can cause the structure to vibrate. These vibrations can lead to structural damage or even collapse if left unchecked. Steel rebars help mitigate these vibrations by absorbing and distributing the forces throughout the structure. By reinforcing the concrete, steel rebars increase the stiffness and strength of the structure, thereby reducing the amplitude of vibrations. They help to resist bending and torsional forces, ensuring that the structure remains stable and secure under various load conditions. Furthermore, steel rebars also play a crucial role in preventing progressive collapse. In the event of localized damage or failure, the rebars act as a safety net, redistributing the load and preventing a complete collapse. This is particularly important in high-rise buildings or structures with complex geometries, where the consequences of structural failure can be catastrophic. Overall, the presence of steel rebars in concrete structures significantly enhances their ability to withstand vibrations and external forces, ensuring the safety and longevity of the structure.

- Q: How are steel rebars stored and transported?

- Construction projects commonly use steel rebars, which are also known as reinforcing bars. The purpose of steel rebars in construction is to provide strength and stability to concrete structures. It is vital to properly store and transport steel rebars to maintain their quality and prevent any damage or accidents. Regarding storage, steel rebars are typically kept in a designated area known as a rebar yard or laydown yard. This area should be clean, well-drained, and free from debris or organic materials. To prevent corrosion or contamination, rebars are usually stacked in bundles or placed on elevated racks to avoid contact with the ground. To ensure safety and easy access, rebars should be organized and labeled based on their sizes and grades. This helps construction workers quickly identify and retrieve the required rebars without causing any disruption or delays in the project. When it comes to transportation, steel rebars are commonly loaded onto trucks or trailers for delivery to construction sites. It is crucial to secure the rebars adequately during transportation to avoid any shifting or movement that could damage the rebars or compromise the safety of the vehicle. Depending on their length and quantity, rebars can be transported in various ways. They can be bundled together using wires, straps, or steel bands to keep them in place. Additionally, wooden or metal supports can be used to prevent the rebars from bending or sagging during transit. During transportation, it is important to consider weight restrictions and road regulations to ensure compliance and safety. If rebars need to be transported over long distances, it is essential to coordinate with logistics companies that specialize in handling heavy and oversized cargo. In conclusion, steel rebars are stored in designated areas like rebar yards, where they are stacked, labeled, and protected from corrosion and contamination. During transportation, rebars are secured using wires, straps, or steel bands and loaded onto trucks or trailers. Proper handling and adherence to regulations are crucial to ensure the safety and integrity of the rebars during storage and transportation.

- Q: How do steel rebars affect the seismic performance of a structure?

- The seismic performance of a structure is significantly impacted by steel rebars. Steel rebars have the primary function of reinforcing concrete and increasing its strength and ductility. This reinforcement is essential in reducing the damaging effects of seismic activity. When an earthquake occurs, a structure is subjected to different forces, such as lateral forces, shear forces, and bending moments. These forces can cause deformation, cracking, or even collapse of the structure. However, steel rebars provide resistance against these forces and help maintain the integrity of the structure. By increasing the tensile strength of concrete, steel rebars enhance its ability to withstand the lateral movement caused by seismic waves. This allows for a more even distribution of forces, minimizing the formation and propagation of cracks and reducing the risk of structural failure. Additionally, steel rebars improve the ductility of the structure. Ductility refers to a material's ability to deform without breaking. During an earthquake, the shaking of the ground can cause the structure to deform and oscillate. Steel rebars enable the structure to absorb and dissipate energy, decreasing the chances of sudden failure. This ductile behavior is particularly important in areas prone to earthquakes as it provides warning signs of potential structural distress, allowing occupants to evacuate safely. Moreover, steel rebars can be strategically placed in critical areas of the structure, such as the beam-column joints, which are highly vulnerable during seismic events. Proper detailing and configuration of rebars in these areas can greatly enhance seismic performance by strengthening connections and preventing premature failure. In conclusion, steel rebars play a critical role in improving the seismic performance of a structure. They enhance the tensile strength of concrete, improve ductility, reduce crack formation, and strengthen critical areas. These factors collectively contribute to a more resilient structure that can better withstand and absorb the forces generated during an earthquake, ultimately ensuring the safety and stability of the building and its occupants.

- Q: Can steel rebars be used in residential construction?

- Yes, steel rebars can be used in residential construction. Steel rebars are commonly used as reinforcement in concrete structures, including residential buildings, to enhance their strength and durability.

- Q: How are steel rebars used in road and pavement construction?

- Steel rebars are used in road and pavement construction to reinforce concrete structures and enhance their strength and durability. The rebars are embedded within the concrete to provide additional tensile strength, prevent cracking and ensure the long-term integrity of the road or pavement.

Send your message to us

Factory 12mm 16mm 20mm A400 Reinforcement Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords