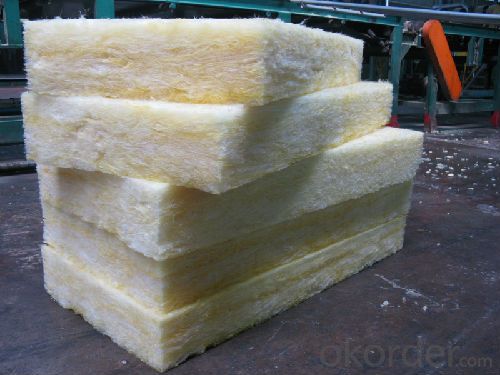

Glass Wool Blanket Bare for Building Thermal Insulation - Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Description

Glass wool blanket is in flexible form for ease of installation over large areas. Both products are available to order with a wide range of density and thickness, and with various types of facing applied.

Standard Size

Item | Unit | Index |

Density | Kg/m3 | 10 - 48 |

Thickness | mm | 25-150 |

Width | mm | 1200 |

Length | mm | 5000-30000 |

Remark:

Other sizes available upon request Facing materials can be applied upon request

Technical Data

Item | Unit | Index |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Thermal Conductivity ( 25℃) | W/mK | 0.038- 0.045 |

Reshrinking Temp | ℃ | ≥250 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

Application

Glass Wool are widely used in public, commercial and residential buildings as well as industrial plants, for applications such as roofing, external wall, partition wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

Material:

Double layers of aluminum foil reinforced with high tensile spring steel wire

Structure: High elastic wire, aluminum foil. A reinforcement model can be required.

Aluminum foil thickness: 0.035mm

- Q: What's the difference between the rock wool and glass wool?

- Glass wool belongs to a category of glass fiber, and is a kind of man-made inorganic fiber. Taking quartz sand, limestone, dolomite and other FIR stone as main raw materials, and is melted into glass after mixed with some pure alkali, sodium borate and other chemical raw materials. In melting state, transfer them into flocculent fibers under the effect of external force, fiber and fiber are in three-dimensional crossing and winded with each other, presenting many little gaps. The gaps can be regarded as air voids. Therefore, glass wool can be regarded as porous materials, it has good heat insulation and sound absorption performance. Glass wool is a kind of spongiform material shaped by making melten glass fibering, it's chemical content belongs to glass and is a kind of inorganic fiber. It has good molding, small bulk density, low thermal conductivity, good thermal insulation and heat insulation, good sound absorption, corrosion resistance and stable chemical performance.

- Q: The difference between glass wool of 50mm and rock wool.

- Glass wool belongs to one of the glass fiber. machine-made fiber cotton wool molten glass fibrosis cotton material belong to glass fiber. type, bulk density, low thermal conductivity, thermal insualtion, acoustic insualtion, anticorrosion, stable chemical performance. Rockwool is also called mineral wool. Use Guangde Shida rock wool and mineral raw materials to make fluffy short fine fibers. Basalt rock wool, pyroxenite, dolomite, iron ore, bauxite can be used to make matrix fiber by going through high temperature melting process and fibrosis.

- Q: Does glass wool belong to the asbestos insulation material?

- No, it isn't

- Q: The advantages of glass wool board

- Features 1, the appearance quality: Surface is smooth, without the practical scars, stains damaged. 2, combustion performance: A level is non-combustible, 3. thermal endurance: 800 degrees. 4, hygroscopicity: & gt; 200% 5, capacity: ≤150 6. the oxygen index: 07, heat conductivity coefficient: 0.04 ~ 0.055 (w / mk) the product is technically in the process through the bonding pressure, trimming, notching, blanking, forming a tongue-and-groove type composite panels, with good integrity, high rigidity and shock resistance, shear resistance mechanical property and thermal insulation, insulation, sound insulation, moisture-proof and other characteristics.

- Q: How to use glass wool for filtering?

- It depends on the filtering materials, if the solid particles are large, you can directly use ordinary funnel but not filter paper, if solid particles are small, you can use filter paper, you can try to use a small amount of filtering materials, and decide in accordance to the filtrate state, the trial is necessary and you will know after lots of trials.

- Q: How about the quoted price of asphalt glass wool felt?

- The sound absorption property of glass?wool?board is related to veneer materials, cavity and cavity's size, the thickness of glass wool board and apparent?density. Test shows that sound absorption property of glass wool board is mostly related to the thickness of board.

- Q: Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Copper contains rubber and plastic. PEF and glass wool are both suitable, but glass wool is not recommend for its poor waterproofing performance, you'd better use rubber and plastic! You can select them with appropriate thickness according to your local winter temperature, or else it will be frozen in winter for it is too thin.

- Q: Which is more suitable for industrial pipe insulation: glass wool or rock wool ?

- If the long-term working temperature is higher than 200 ℃, glass wool is not suitable. Weinai thermal insulation blanket is a good piping insulation material. Besides, glass wool has better thermal insulation property than rock wool, but poorer temperature resistance.

- Q: What are the features of glass wool decorative acoustic?panel?absorber suspended ceiling?

- 1, Excellent decorative effect. Mineral wool acoustic board has various patterns and reliefs, stereoscopic model, reflecting ancient glory and modern fashion, really refreshing. 2. good thermal insulation property. Mineral wool acoustic board is good thermal insulation material which can be make the house warm in winter and cool in summer and save energy for users because it has low heat conductivity coefficient. 3. sound absorption and noise reduction. The main raw material of mineral wool acoustic board is ultra-fine mineral wool fibre whose density is about 200 ~ 450Kg / m, so it has many perforative micropores which can effectively absorb sound waves and reduce sound wave reflection so as to improve indoor tone quality and reduce noise. 4. fireproof. Since the mineral wool is an inorganic material, it will not burn, and mineral wool acoustic board has very low content of organics, thus making it meeting requirements of Class B1 non-combustible. And our products have been able to reach non-combustible Class A . 5. Green and eco-friendly, regulating air. Mineral wool acoustic board does not contain harmful substances. It contains active groups which can absorb harmful gases in the air and its porous structure can absorb and release water molecules so as to purify the air and adjust indoor air humidity . 6. moisture-proof and insulation. Since mineral wool acoustic board contains a large number of micropores and has releatively large surface area, it can absorb and release water molecules in the air and regulate indoor air humidity. It can be regarded as a decorative board that can breath.

- Q: What are the hardnesses of rock wool and glass wool respectively? Are there any requirements on saw blade?

- Almost the same. It should be used universally.

Send your message to us

Glass Wool Blanket Bare for Building Thermal Insulation - Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords