ETP for Metal Package of Industrial Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of ETP for Metal Package of Industrial Chemical Useage Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the ETP for Metal Package of Industrial Chemical Useage

Salient Features of DR Tinplate

The salient feature of DR Tinplate is the combination of higher strength and sufficient ductility, which enables much thinner Tinplate to be used, compared to Single Reduced Tinplate resulting in Substantial economic savings.

According to the steel chemistry and annealing process, the second reduction (DR08) can be between 27% to 40%, thereby producing strengths upto 550 +/-50 N/mm2, whereas single reduced material has strength less than 450 N/mm2 &DR 09 (Hard DR) is produced at temper mill with reduction % in range of 27-35 % & will strength upto 690 N/mm2 to the produced material.

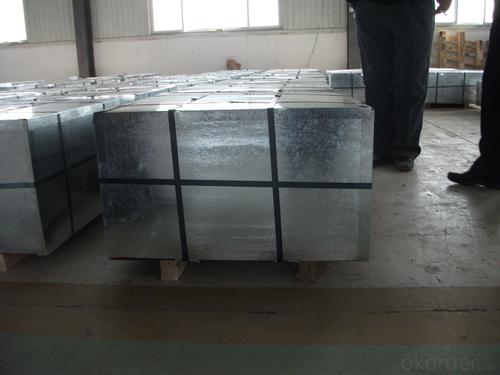

3.ETP for Metal Package of Industrial Chemical Useage Images

4.ETP for Metal Package of Industrial Chemical Useage Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of ETP for Metal Package of Industrial Chemical Useage

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q: How does tinplate contribute to the protection of textile products?

- Tinplate contributes to the protection of textile products by providing a durable and corrosion-resistant packaging material. It acts as a barrier against moisture, oxygen, and light, preventing the deterioration of textile products during storage and transportation. Tinplate's protective properties help maintain the quality, color, and integrity of textiles, ensuring they reach consumers in optimal condition.

- Q: What are the main safety regulations for tinplate production and use?

- The main safety regulations for tinplate production and use include ensuring proper handling and storage of tinplate materials, conducting regular maintenance and inspections of equipment to prevent accidents, implementing proper ventilation systems to control fumes and dust, providing personal protective equipment (PPE) to workers, and following established protocols for waste disposal to minimize environmental hazards. Additionally, tinplate manufacturers and users must comply with occupational health and safety standards, such as providing training programs for employees, promoting safe work practices, and adhering to local and international regulations governing the production and use of tinplate products.

- Q: What are the different ways to seal tinplate containers?

- There are several different ways to seal tinplate containers, including using a metal lid with a rubber gasket, using a plastic or paper lid with a heat-sealed lining, using a twist-off cap with a tamper-evident seal, and using a peel-off foil seal.

- Q: What is tinplate?

- Tinplate refers to thin sheets of steel that have been coated with a layer of tin. It is primarily used in the packaging industry for manufacturing cans and containers due to its corrosion resistance and ability to preserve the quality of food and beverages.

- Q: Can tinplate be used for automotive parts?

- Yes, tinplate can be used for automotive parts. Tinplate, which is a thin steel sheet coated with a layer of tin, is often used in the automotive industry for various applications such as fuel tanks, exhaust systems, and body panels. Its corrosion-resistant properties, durability, and formability make it suitable for automotive components.

- Q: How is tinplate coated for construction materials?

- Tinplate is coated for construction materials through a process called electrolytic tin-plating. In this process, a thin layer of tin is applied to the surface of steel or iron sheets by immersing them in an electrolyte bath and passing an electric current through it. This creates a chemical reaction that deposits the tin onto the material, providing it with a protective coating against corrosion and improving its durability for construction purposes.

- Q: How does tinplate perform in terms of durability and longevity?

- Tinplate is highly durable and long-lasting due to its corrosion-resistant properties. It can withstand harsh environmental conditions and is resistant to rust and oxidation, making it ideal for various applications where durability is crucial. Additionally, tinplate's longevity is further enhanced through proper coating and maintenance, ensuring its longevity even in demanding environments.

- Q: Can tinplate be used for signage and displays?

- Yes, tinplate can be used for signage and displays. Tinplate is a versatile material that is strong, durable, and resistant to corrosion, making it suitable for outdoor and indoor applications. Additionally, it can be easily formed into various shapes and sizes, allowing for creative and visually appealing signage and display designs.

- Q: How does tinplate compare to other packaging materials in terms of recyclability?

- Tinplate is highly recyclable and often considered to be one of the most sustainable packaging materials available. It can be easily separated from other materials during the recycling process and has a high recycling rate, making it a preferred choice for environmentally conscious consumers and industries.

- Q: How does tinplate compare to aluminum packaging in terms of cost?

- Tinplate packaging is generally more cost-effective compared to aluminum packaging. Tinplate is known for its lower production and raw material costs, making it a more affordable option for packaging. On the other hand, aluminum packaging tends to be more expensive due to the higher cost of aluminum as a raw material and its energy-intensive production process. Therefore, when considering cost, tinplate is often a more economical choice for packaging solutions.

Send your message to us

ETP for Metal Package of Industrial Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords