Prime ETP for Metal Package of Industrial or Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Prime ETP for Metal Package of Industrial or Chemical Useage Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the Prime ETP for Metal Package of Industrial or Chemical Useage

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

While once more widely used, the primary use of tinplate now is the manufacture of tin cans. Formerly, tinplate was used for cheap pots, pans and other holloware

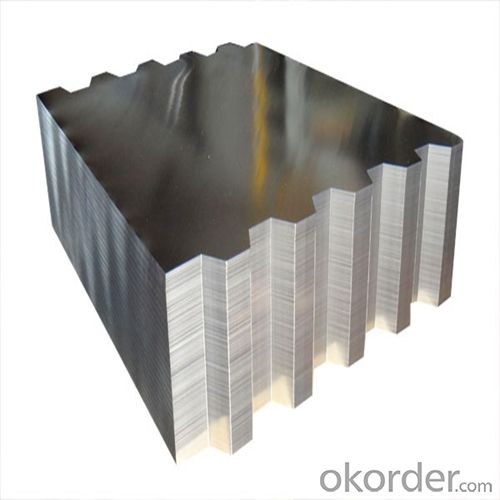

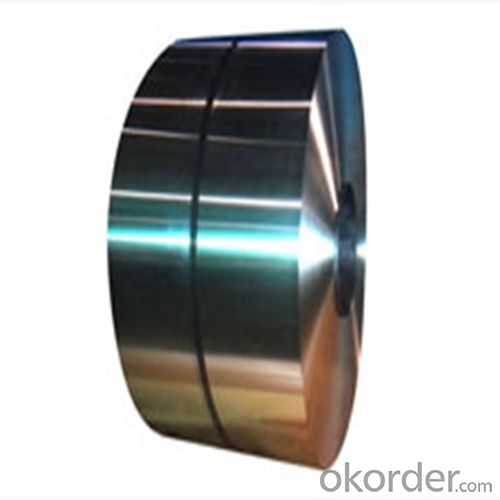

3.Prime ETP for Metal Package of Industrial or Chemical Useage Images

4.Prime ETP for Metal Package of Industrial or Chemical Useage Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Prime ETP for Metal Package of Industrial or Chemical Useage

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q: How does tinplate contribute to the freshness of pet food?

- Tinplate contributes to the freshness of pet food by providing a protective barrier against oxygen, moisture, and light. This helps to prevent spoilage and maintain the quality of the food, ensuring it stays fresh for a longer period of time.

- Q: How does tinplate contribute to the functionality of household goods?

- Tinplate contributes to the functionality of household goods by providing a durable and corrosion-resistant coating that protects the underlying material from moisture, oxygen, and other environmental factors. This ensures that household items such as cans, containers, and appliances have a longer lifespan and remain in good condition. Additionally, tinplate's versatility allows for easy shaping and forming, enabling the creation of various functional and aesthetically pleasing designs for household goods.

- Q: How does tinplate compare to other packaging materials in terms of cost?

- Tinplate is generally considered to be more expensive than other packaging materials such as aluminum or plastic. However, its durability, protective qualities, and recyclability make it a cost-effective choice in certain industries where the preservation of product quality is crucial, like food and beverages.

- Q: How does tinplate contribute to the durability of gardening tools?

- Tinplate contributes to the durability of gardening tools by providing a protective coating that prevents corrosion and rusting, ensuring the tools last longer even in harsh outdoor conditions.

- Q: What are the advantages of tin packaging?

- Mature technology and high production efficiency: the production of tinplate has a long history, has a mature skill set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: How does tinplate contribute to the reduction of carbon emissions?

- Tinplate contributes to the reduction of carbon emissions through its recyclability and lightweight nature. As tinplate is made from steel, it can be easily recycled, reducing the need for new production and saving energy. Additionally, tinplate's lightweight properties make it more fuel-efficient during transportation, resulting in lower carbon emissions throughout its lifecycle.

- Q: What are the advantages of using tinplate for stationery and office supplies?

- One advantage of using tinplate for stationery and office supplies is its durability. Tinplate is highly resistant to corrosion and is less likely to get damaged or dented, ensuring that the supplies made from it will last longer. Additionally, tinplate has a smooth surface, making it easy to clean and maintain. Another advantage is its aesthetic appeal. Tinplate can be easily customized and printed on, allowing for creative and visually appealing designs on stationery and office supplies. Lastly, tinplate is also eco-friendly as it is a recyclable material, contributing to a more sustainable approach in the production and use of these supplies.

- Q: How does tinplate contribute to food safety?

- Tinplate contributes to food safety by providing a protective barrier between the food and the metal surface, preventing any interaction that could potentially contaminate or alter the taste of the food. Additionally, tinplate is resistant to corrosion, ensuring the integrity of the packaging and preventing any unwanted substances from entering the food.

- Q: What are the advantages of using tinplate for beverage cans?

- Tinplate offers several advantages for beverage cans, including its excellent resistance to corrosion, its ability to maintain the freshness and taste of the beverage, its high strength-to-weight ratio, its ease of recyclability, and its cost-effectiveness.

- Q: How is tinplate corrosion resistant?

- Tinplate is corrosion resistant due to the thin layer of tin that is applied to its surface. Tin acts as a protective barrier, preventing the underlying iron or steel from coming into contact with moisture or oxygen, which are the main causes of corrosion.

Send your message to us

Prime ETP for Metal Package of Industrial or Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords