ERW steel pipe with high quality and cerficate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 8000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Welded Steel Tube:

Welded Steel Tube is formed by drawing a solid billet over a piercing rod to create the hollow shell. We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of welded pipe and professioanl service.

2、Main Features of the Welded Steel Tube:

• High manufacturing accuracy

• The higher strength

• The small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Satisfy price

3、Welded Steel Tube Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

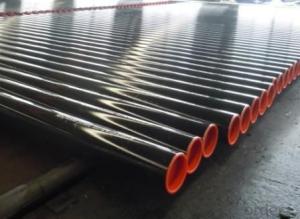

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Welded Steel Tube:

①How is the quality of your products?

Our products are strictly in accordance with international and domestic standard. We test on every pipe before delivery. Any quality certification or testing report you want to see, please tell us.

Guaranteed: If products’ quality is not in accordance with description as we provide or the promise before you place order, we promise 100% refund.

②How about the price?

Yes, we are factory and be capable of offering you the lowest price. One of our policy is that “ to save time and be absolutely honest with our business relationship, we quote as low as possible for every client, and discount can be given according to the quantity”, if you are interested in bargain and dissatisfy our factory price, just don’t waste your time. Our quotation is professional.

③Why should you choose us?

Choice happens because of our quality and price. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), fast goods delivery, outstanding customer solution proposals. Our service formula: good quality + good price + good service=customer’s trust.

SGS test is available. Customer inspection before shipping is welcome. Third party inspection is OK.

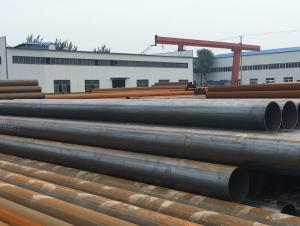

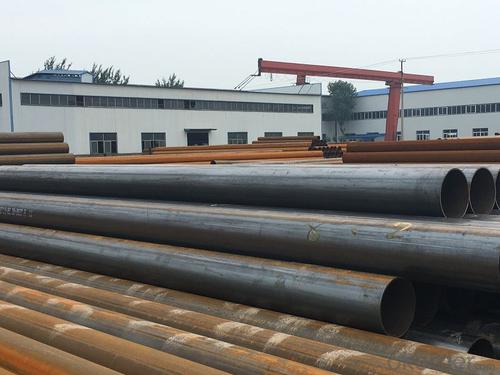

6、 Welded Steel Tube Images:

- Q: What are the different methods of pipe cutting for steel pipes?

- There exists a variety of techniques for cutting steel pipes, each tailored to specific circumstances and demands. Some of the most prevalent techniques are as follows: 1. Manual Pipe Cutters: These handheld tools are frequently employed for cutting smaller steel pipes. They typically feature a rotating cutting wheel that gradually creates a groove until the pipe is severed. Portable and relatively user-friendly, manual pipe cutters are suitable for on-site cutting tasks. 2. Hacksaw: The use of a hacksaw is a traditional and cost-effective means of cutting steel pipes. This method requires physical exertion and time; however, it can effectively cut pipes with smaller diameters. It is crucial to use a fine-toothed blade and apply steady pressure to ensure a clean and precise cut. 3. Reciprocating Saw: Also known as a sawzall, the reciprocating saw is a power tool that employs a back-and-forth cutting motion to swiftly and efficiently cut through steel pipes. These versatile saws can accommodate different types of blades to handle various pipe sizes and thicknesses. 4. Band Saw: Band saws are commonly employed in industrial settings for the purpose of cutting large steel pipes. These saws feature a continuous loop of teethed metal blade that moves on wheels, enabling precise and rapid cutting. Band saws are ideal for cutting large-diameter pipes and can be operated manually or fully automated for high-volume cutting tasks. 5. Pipe Cutting Machines: Pipe cutting machines are often utilized to achieve precise and consistent cuts. These machines are designed to cut steel pipes swiftly and accurately, making them suitable for large-scale industrial applications. Depending on the machine and requirements, various cutting methods like abrasive cutting, flame cutting, or plasma cutting can be employed. It is important to note that the selection of a pipe cutting method depends on factors such as pipe diameter, thickness, location, precision requirements, and available resources. It is imperative to adhere to proper safety precautions when working with any cutting method to prevent injury or damage to the pipes.

- Q: What is the outer diameter and wall thickness of the welded steel pipe of national standard DN250?

- DN250 is the nominal diameter, the outer diameter of the steel pipe is 273mm, the thickness is above 6.5mm.

- Q: How do steel pipes compare to other materials like PVC or copper pipes?

- Steel pipes have several advantages over other materials like PVC or copper pipes. Firstly, steel is a very strong and durable material, making steel pipes ideal for handling high-pressure applications. They can withstand extreme temperatures and are resistant to corrosion, making them suitable for both indoor and outdoor use. PVC pipes, on the other hand, are not as strong and are more prone to cracking and breaking under pressure or in extreme temperatures. Copper pipes, though durable, can be susceptible to corrosion and may require additional protective coatings. Secondly, steel pipes have a longer lifespan compared to PVC or copper pipes. They are known for their longevity and can last for several decades without needing replacement. PVC pipes, while relatively inexpensive, have a shorter lifespan and may need to be replaced more frequently. Copper pipes, though durable, can also corrode over time and may require maintenance or replacement. Another advantage of steel pipes is their ability to handle a wide range of fluids and substances. They are commonly used in industrial applications where there may be chemicals or corrosive materials present. PVC pipes, on the other hand, may not be suitable for handling certain chemicals or substances as they can react and cause damage to the pipe. Copper pipes, while generally safe for carrying water, may not be ideal for conveying certain chemicals or fluids. Additionally, steel pipes have excellent fire resistance properties. In the event of a fire, steel pipes can withstand high temperatures and maintain their structural integrity, ensuring the safety and protection of the surrounding area. PVC pipes, on the other hand, can melt or deform under high heat, potentially causing structural damage. Copper pipes, while not as prone to melting, can still be affected by extreme heat and may lose their strength. However, there are a few drawbacks to steel pipes as well. They tend to be heavier and more difficult to install compared to PVC or copper pipes. Additionally, steel pipes can be more expensive upfront, especially when compared to PVC pipes. However, considering their durability and longevity, steel pipes may offer better value in the long run. In conclusion, steel pipes offer several advantages over other materials like PVC or copper pipes. They are strong, durable, resistant to corrosion, and have a longer lifespan. They can handle high-pressure applications and a wide range of fluids, making them suitable for various industrial and commercial uses. While they may be more expensive and difficult to install, the benefits of steel pipes make them a reliable and cost-effective choice in many applications.

- Q: Who knows what is the difference between double submerged arc welded pipe and longitudinal submerged arc welding?

- Double submerged arc welding is also a kind of longitudinal submerged arc welding.

- Q: Can steel pipes be used for fire sprinkler systems?

- Yes, steel pipes can be used for fire sprinkler systems.

- Q: How do you determine the pipe schedule for steel pipes?

- The pipe schedule for steel pipes is determined based on several factors including the pressure rating, wall thickness, and outer diameter of the pipe. The pipe schedule is a standardized system used to classify the thickness of pipe walls, and it helps ensure compatibility and safety in various applications. To determine the pipe schedule for steel pipes, you need to consider the maximum pressure the pipe will be subjected to. This is usually expressed in pounds per square inch (psi) or bars. The pressure rating of a pipe indicates the maximum pressure it can withstand without failure or leakage. The higher the pressure rating, the thicker the pipe walls need to be. The wall thickness of the pipe is another important factor in determining the pipe schedule. It is typically expressed in inches or millimeters. The wall thickness is directly related to the pressure rating, as thicker walls can handle higher pressures. The American National Standards Institute (ANSI) provides a set of standard wall thicknesses for steel pipes known as the "pipe schedule." The outer diameter of the pipe is also considered when determining the pipe schedule. The outer diameter can vary depending on the specific application and requirements. It is important to choose a pipe with the appropriate outer diameter to ensure proper fit and compatibility with fittings, valves, and other components. In summary, the pipe schedule for steel pipes is determined by considering the maximum pressure, wall thickness, and outer diameter. By matching these factors with the appropriate pipe schedule, you can ensure that the steel pipe will be suitable for its intended use and capable of withstanding the required pressure.

- Q: How can two smooth steel pipes be joined? The size of the two pipe is different (except for welding)

- Fastener type steel pipe scaffold, fastener is the connection between steel pipe and steel pipe, and its form has three kinds, namely right angle fastener, rotating fastener, butt fastener

- Q: What is the difference between steel pipes and fiberglass pipes?

- The main difference between steel pipes and fiberglass pipes lies in their composition and properties. Steel pipes are made of metal and are known for their strength, durability, and resistance to high temperatures and pressure. They are commonly used in industrial settings and for transporting liquids and gases. On the other hand, fiberglass pipes are made of glass fibers embedded in a resin matrix, providing them with excellent corrosion resistance, lightweight properties, and insulation capabilities. Fiberglass pipes are often used in applications where corrosion is a concern, such as in chemical processing plants or wastewater treatment facilities.

- Q: Can steel pipes be used for petrochemical plants?

- Yes, steel pipes can be used for petrochemical plants. Steel pipes are often preferred in petrochemical plants due to their high strength, durability, and resistance to corrosion, making them ideal for handling various chemicals and substances involved in petrochemical processes. Additionally, steel pipes can withstand high pressure and temperature conditions commonly encountered in petrochemical plants, making them a reliable choice for transporting fluids and gases.

- Q: The plastic pipe and steel pipe difference

- In fact, including the steel plastic pipe plastic pipe, but on the market all the steel plastic pipe and plastic lining steel pipe is synonymous, lined with plastic pipe is made of galvanized steel pipe internal set of plastic pipe manufacturing process, process using high pressure steam to both adhesion.

Send your message to us

ERW steel pipe with high quality and cerficate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 8000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords