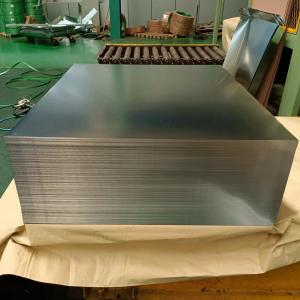

Electroytic Tinplate Sheet SPTE ETP for Packaging Foodstuffs Beverages

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Electroytic Tinplate Sheet SPTE ETP for Packaging Foodstuffs Beverages

Tinplate has a beautiful metallic luster as well as excellent properties in corrosion resistance and paint-ability.

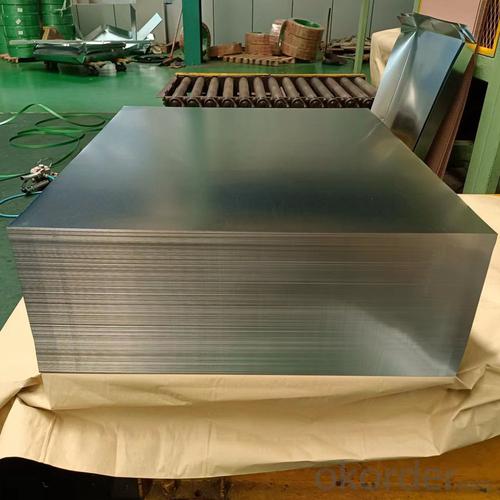

Available Specifications and Sizes

| Steel Type | MR, SPCC |

| Temper (BA&CA) | T1~T5, DR8~DR10 |

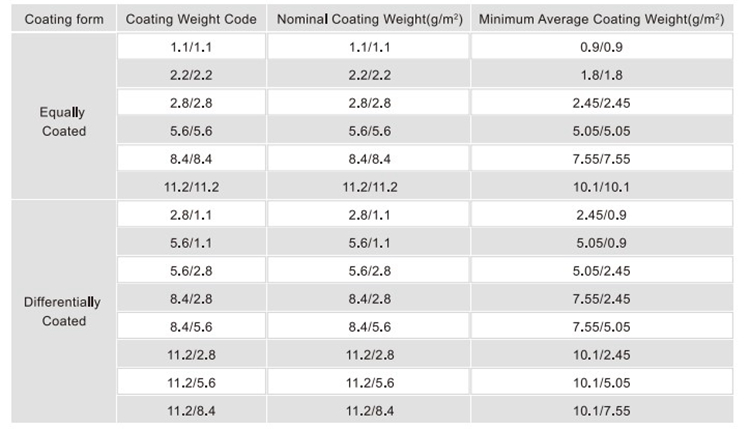

| Coating | 1.1~11.2g/㎡ |

| Thickness & Tolerance | 0.15~0.5mm (Tolerance: ±0.01mm) |

| Width & Tolerance | 600~1010mm (Tolerance: +2/-0mm) |

| I.D | 508 mm |

| Coil Weight | 3~10 MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface Finish | Bright, Stone, Silver, Matte, (B, R, R2, S, S1, S2, M) |

| Quantity for 20 Feet FCL | 20~25 Tons |

| Package | Seaworthy Export Standard Wooden Pallet |

Special specifications are available on customers' requirements

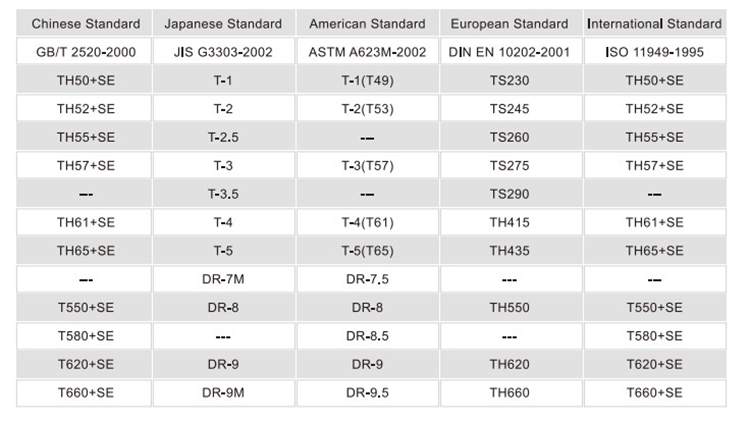

Standard Comparison for Temper

Tin coating weight

1.ETP

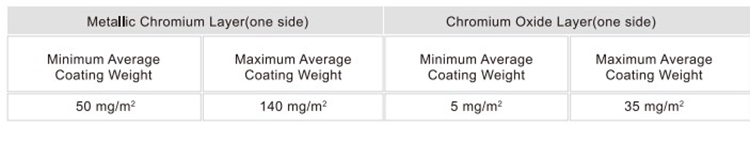

2.TFS

Applications of Tinplate and TFS: Consumer Packaging and Industrial Packaging

| TINPLATE | ETP is primarily used for packaging foodstuffs and beverages, but it is also used in containers for oils, grease, paints, polishes, chemicals and many other products. Aerosol containers,caps and closures are also made from ETP. |

| TFS | TFS are most frequently used for can tops, screws and lug caps, snap and press-on closures and shallow-drawn food cans. |

Miscellaneous

| in Electronics | Electrodes, Cable tape, Magnetic screen covers, etc. |

| in Engineering | Automotive oil filters. Automotive air filters, Gaskets, etc. |

| in Construction | Gas meter internal components, Heat exchangers, cookware, shelving, etc. |

Package

- Q: Can tinplate be used for packaging perishable goods?

- Yes, tinplate can be used for packaging perishable goods. Tinplate is known for its excellent resistance to corrosion and its ability to provide an airtight seal, making it suitable for preserving the freshness and quality of perishable products such as food and beverages.

- Q: What are the common thicknesses of tinplate?

- The common thicknesses of tinplate range from 0.13mm to 0.49mm, with increments of 0.01mm.

- Q: Cookies with tinplate packaging has what advantage?

- The decoration is exquisite: the metal material has good printing performance; the design trademark is bright and beautiful; the packaging container made by it is noticeable, and it is a kind of good sale packing.

- Q: What are the main factors affecting tinplate market growth?

- The main factors affecting tinplate market growth include the demand for packaged food and beverages, the increasing use of tinplate in the automotive industry for cans, cans, and containers, government regulations and policies regarding packaging materials, and the overall economic conditions and consumer spending.

- Q: Can tinplate be used for packaging frozen foods?

- Yes, tinplate can be used for packaging frozen foods. It has excellent durability and resistance to temperature fluctuations, making it suitable for preserving the quality and freshness of frozen food products. Additionally, tinplate offers a high level of protection against moisture, light, and oxygen, further ensuring the integrity of the frozen food during storage and transportation.

- Q: What are the safety considerations when handling tinplate?

- When handling tinplate, it is important to consider several safety precautions. Firstly, tinplate can have sharp edges, so it is essential to wear protective gloves to prevent cuts or injuries. Additionally, tinplate may contain sharp metal burrs that can cause cuts or punctures. Therefore, it is advisable to handle the material carefully and avoid dragging or sliding it across surfaces. Furthermore, tinplate is susceptible to rusting, so it should be stored in a dry environment to prevent corrosion. Lastly, tinplate can be heavy, so proper lifting techniques should be employed to avoid strains or back injuries.

- Q: What are the main applications of tinplate in the medical industry?

- Tinplate is primarily used in the medical industry for packaging pharmaceutical products, such as pills and tablets, due to its excellent barrier properties against moisture, light, and oxygen. It is also commonly used for medical device packaging, ensuring the sterility and protection of sensitive equipment. Additionally, tinplate is utilized in the production of medical instruments and tools, as it provides a durable and corrosion-resistant coating.

- Q: What are the typical production volumes for tinplate?

- The typical production volumes for tinplate vary depending on market demand and specific manufacturing capabilities. However, on a global scale, millions of metric tons of tinplate are produced each year to meet the needs of various industries such as packaging, automotive, electronics, and construction.

- Q: What are the main applications of tinplate in the sports equipment industry?

- Tinplate is commonly used in the sports equipment industry for the production of metal containers, such as cans and bottles, which are utilized for packaging various sports drinks, supplements, and other products. Additionally, tinplate is employed in the manufacturing of protective coatings for certain sports equipment to enhance durability and prevent rusting or corrosion.

- Q: How does tinplate compare to aluminum packaging in terms of cost?

- Tinplate packaging is generally more cost-effective compared to aluminum packaging. Tinplate is known for its lower production and raw material costs, making it a more affordable option for packaging. On the other hand, aluminum packaging tends to be more expensive due to the higher cost of aluminum as a raw material and its energy-intensive production process. Therefore, when considering cost, tinplate is often a more economical choice for packaging solutions.

Send your message to us

Electroytic Tinplate Sheet SPTE ETP for Packaging Foodstuffs Beverages

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords