Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SHEET SPECIFICATION

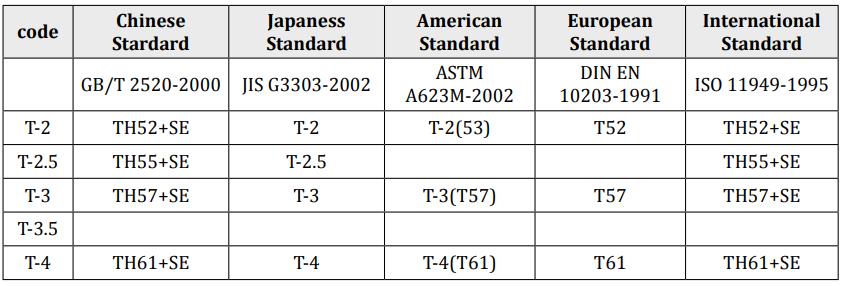

Reference standard: GB/T 2520-2000, JIS G3303-2002 and DIN EN 10203-1991

Raw material: MR and SPCC

Thickness: 0.13 to 0.5mm

Width: 600-1050mm

Length: maximum 1200mm

Temper: T1~T5, DR8~DR10

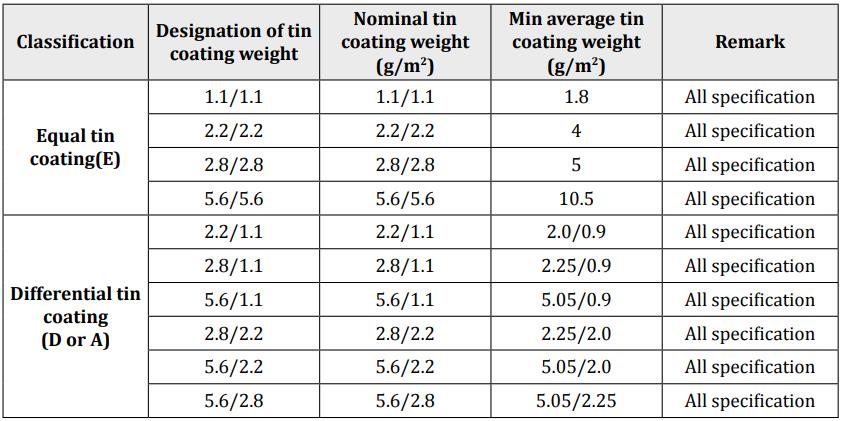

Tin coating: 1.1g~11.2g We can produce according to customer’s requests.

Applications: paint, chemical and other usage can make battery, electric cable and other industries

Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

Stardard

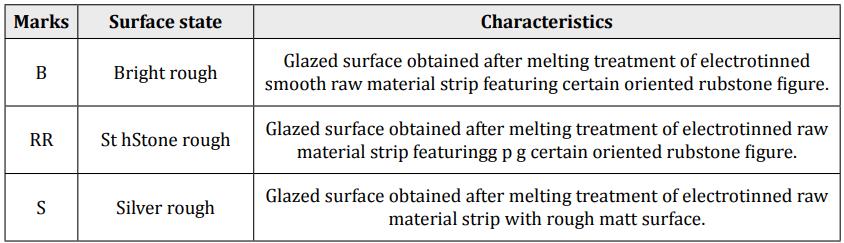

Surface

Coating

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

◆ Chemicals and painting cans

◆ Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans

◆ Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

◆ Sea food cans

◆ Crown corks, easy open ends (EOE)

◆ Electrical machinery parts

◆ Bakeware and household kitchen parts

- Q: What are the main properties of tinplate?

- Tinplate is primarily known for its corrosion resistance, durability, and versatility. It is a thin steel sheet coated with a layer of tin, which provides a protective barrier against rust and oxidation. This makes tinplate suitable for packaging various food and beverage products. Additionally, its malleability allows for easy shaping and forming, making it ideal for intricate designs and embossing. Tinplate also exhibits excellent solderability, making it a preferred material for manufacturing cans, containers, and other metal products.

- Q: How does tinplate perform in microwave ovens?

- Tinplate is not suitable for use in microwave ovens as it can cause sparks and potentially damage the oven.

- Q: How does tinplate packaging protect against moisture and oxygen?

- Tinplate packaging protects against moisture and oxygen due to its unique properties. The tin coating acts as a barrier, preventing the penetration of moisture and oxygen into the packaged product. It creates a protective layer that effectively shields the contents from these elements, ensuring their quality and freshness over an extended period of time.

- Q: How is tinplate coated for corrosion resistance?

- Tinplate is coated for corrosion resistance through a process called electrolytic tinning. This involves immersing the tinplate in a bath containing a tin salt solution and passing an electric current through it. The electric current causes tin ions to bond with the surface of the tinplate, forming a thin layer of tin that acts as a protective barrier against corrosion.

- Q: What is the process for printing on tinplate?

- The process for printing on tinplate typically involves several steps. First, the tinplate sheets are cleaned and coated with a layer of primer to ensure proper adhesion of the ink. Then, the desired design or artwork is printed onto the tinplate using specialized printing techniques such as lithography or offset printing. After the printing is complete, the tinplate is usually coated with a protective varnish or lacquer to enhance its durability and resistance to corrosion. The printed tinplate sheets can then be further processed into various products, such as tin cans or decorative tin containers.

- Q: 0.25mm which melting point is low in tin plate and tin plate?

- Tin plated steel sheet and strip, also known as tinplate, the steel plate (belt) surface tin plated, has good corrosion resistance, non-toxic, can be used as packaging material cans, inside and outside the cable sheath, telecommunications instrument parts, flashlight and other hardware.

- Q: What are the main challenges in tinplate manufacturing?

- Some of the main challenges in tinplate manufacturing include ensuring consistent quality and uniform coating thickness, managing the complex process of tin coating application, minimizing production costs without compromising product integrity, and meeting environmental regulations related to waste disposal and emissions control. Additionally, maintaining efficient supply chain management and addressing the increasing demand for sustainable packaging solutions are also significant challenges in tinplate manufacturing.

- Q: Can tinplate be used for packaging fragile items?

- Yes, tinplate can be used for packaging fragile items. Tinplate is a durable material that provides excellent protection against impact and external factors, making it suitable for packaging delicate and fragile items.

- Q: What are the causes of tinplate rusting and how to prevent them?

- Attachment of impurities. The impurity is mainly caused by the difference of the impurity with the iron sheet, or the impurity adsorbed the water on the iron sheet to form a galvanic cell.

- Q: How does tinplate perform in terms of aroma and flavor preservation?

- Tinplate is highly effective in preserving aroma and flavor due to its excellent barrier properties. It forms a protective layer that prevents oxygen, light, and moisture from entering the packaging, thereby preserving the quality and freshness of the product inside.

Send your message to us

Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords