Electroytic Tinplate Coil SPTE ETP for Packaging Consumer Industrial Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Electroytic Tinplate Coil SPTE ETP

Tinplate has a beautiful metallic luster as well as excellent properties in corrosion resistance and paint-ability.

Available Specifications and Sizes

| Steel Type | MR, SPCC |

| Temper (BA&CA) | T1~T5, DR8~DR10 |

| Coating | 1.1~11.2g/㎡ |

| Thickness & Tolerance | 0.15~0.5mm (Tolerance: ±0.01mm) |

| Width & Tolerance | 600~1010mm (Tolerance: +2/-0mm) |

| I.D | 508 mm |

| Coil Weight | 3~10 MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface Finish | Bright, Stone, Silver, Matte, (B, R, R2, S, S1, S2, M) |

| Quantity for 20 Feet FCL | 20~25 Tons |

| Package | Seaworthy Export Standard Wooden Pallet |

Special specifications are available on customers' requirements

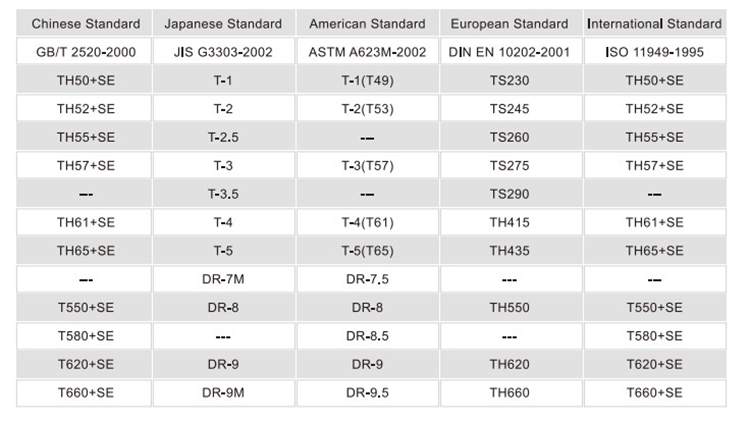

Standard Comparison for Temper

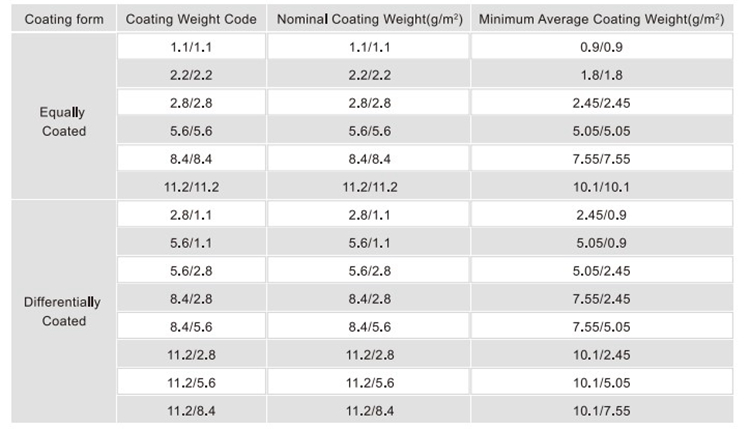

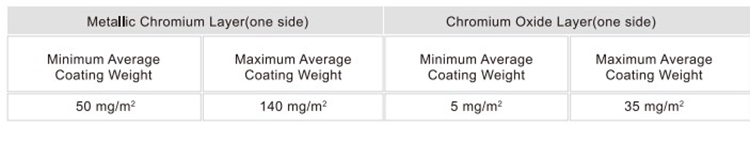

Tin coating weight

1.ETP

2.TFS

Applications of Tinplate and TFS: Consumer Packaging and Industrial Packaging

| TINPLATE | ETP is primarily used for packaging foodstuffs and beverages, but it is also used in containers for oils, grease, paints, polishes, chemicals and many other products. Aerosol containers,caps and closures are also made from ETP. |

| TFS | TFS are most frequently used for can tops, screws and lug caps, snap and press-on closures and shallow-drawn food cans. |

Miscellaneous

| in Electronics | Electrodes, Cable tape, Magnetic screen covers, etc. |

| in Engineering | Automotive oil filters. Automotive air filters, Gaskets, etc. |

| in Construction | Gas meter internal components, Heat exchangers, cookware, shelving, etc. |

Package

- Q: What are the environmental impacts of tinplate production?

- The production of tinplate has several significant environmental impacts. Firstly, the extraction of tin from its ore requires extensive mining operations, which can result in habitat destruction, soil erosion, and water pollution. Additionally, the smelting process releases various air pollutants, including sulfur dioxide and particulate matter, contributing to air pollution and potentially causing respiratory issues. Furthermore, the tin coating process involves the use of chemicals, such as acids and solvents, which can lead to water contamination if not properly managed. Lastly, the disposal of tinplate waste, including scrap and byproducts, can pose challenges in terms of proper handling and recycling, potentially leading to landfill accumulation. Overall, the environmental impacts of tinplate production underline the importance of adopting sustainable practices and promoting circular economy principles in this industry.

- Q: What are the main applications of tinplate in the pharmaceutical industry?

- Tinplate is commonly used in the pharmaceutical industry for the production of packaging materials such as containers, tubes, and caps. It provides excellent barrier properties against moisture, light, and gases, ensuring the integrity and stability of pharmaceutical products. Tinplate is also easy to sterilize, making it suitable for storing drugs and medical devices. Additionally, its durability and tamper-proof properties make it a reliable choice for ensuring product safety and extending shelf life in the pharmaceutical industry.

- Q: What are the common widths of tinplate?

- The common widths of tinplate typically range from 600mm to 1200mm.

- Q: What are the typical lead times for tinplate tooling?

- The typical lead times for tinplate tooling can vary depending on the complexity of the project and the specific requirements. However, on average, lead times for tinplate tooling can range from a few weeks to a couple of months.

- Q: Can tinplate be used for aerospace applications?

- Yes, tinplate can be used for certain aerospace applications. It is commonly used for manufacturing small parts and components such as fasteners, connectors, and electrical contacts. However, it is not suitable for high-stress or extreme temperature conditions that are often encountered in aerospace applications. In such cases, more specialized and durable materials like titanium or stainless steel are preferred.

- Q: What are the common sizes and shapes of tinplate products?

- Common sizes and shapes of tinplate products include cans, containers, boxes, and trays. These products come in various dimensions and forms to cater to different packaging needs and requirements.

- Q: What are the common decorative options for tinplate packaging?

- Some common decorative options for tinplate packaging include embossing, lithography, and spot varnishing. Embossing involves creating raised designs on the surface of the tinplate, adding texture and visual interest. Lithography is a printing technique that allows for vibrant colors and intricate designs to be applied to the tinplate. Spot varnishing is a method of selectively applying a glossy finish to certain areas of the packaging, creating a contrasting effect. These decorative options can enhance the overall aesthetic appeal of tinplate packaging and make it more visually appealing to consumers.

- Q: What are the common quality standards for tinplate?

- The common quality standards for tinplate include factors such as the thickness and uniformity of the tin coating, the absence of defects such as scratches or dents, the adhesion and durability of the tin coating, and compliance with specific international regulations related to food safety and environmental protection.

- Q: How big is the difference between tinplate and stainless steel 316L?

- 316L is a kind of austenitic stainless steel with excellent corrosion resistance. The tinplate is not comparable. 316L is superior to tinplate in appearance, corrosion resistance, heat resistance and strength. Of course, the price is much higher than that of tinplate.

- Q: What are the disadvantages of using tinplate in packaging?

- One disadvantage of using tinplate in packaging is that it can be more expensive compared to alternative packaging materials such as plastic or cardboard. Additionally, tinplate is prone to corrosion, which can compromise the integrity of the packaging and lead to product spoilage. It is also heavier than other materials, which can increase shipping costs and carbon footprint. Finally, tinplate is not as easily recyclable as some other packaging materials, contributing to environmental concerns.

Send your message to us

Electroytic Tinplate Coil SPTE ETP for Packaging Consumer Industrial Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords