Electrolytic Tinplate Food Can Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Description

Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

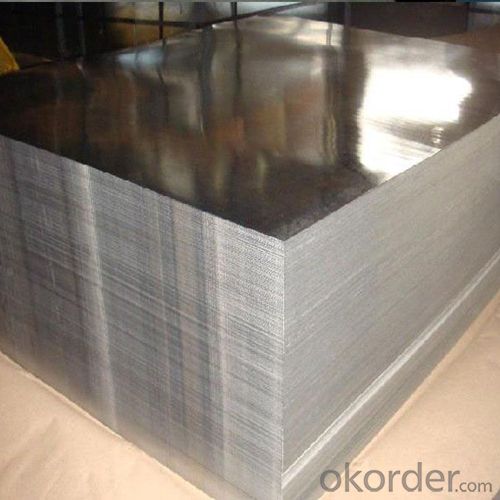

3.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Images

4.Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

-What your tinplate material is used for ?

Tinplate is widely used for the packaging of products. Such as food cans,

beverage cans, pet cans, closures, general line cans and so on.

Printed Tinplate is offered!!

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q: What are the main applications of tinplate in the pharmaceutical industry?

- Tinplate is primarily used in the pharmaceutical industry for packaging purposes. Its main applications include the production of tinplate cans, containers, and closures. These tinplate packaging solutions provide a reliable and durable barrier against moisture, light, and oxygen, ensuring the protection and preservation of pharmaceutical products. Additionally, tinplate is also used for labeling and promotional purposes due to its excellent printability and aesthetic appeal.

- Q: What are the benefits of using tinplate for paint cans?

- One of the main benefits of using tinplate for paint cans is its exceptional durability and resistance to corrosion. Tinplate is a coated steel material that provides a protective barrier against moisture, preventing rusting and extending the lifespan of the paint cans. Additionally, tinplate is a lightweight material, making it easy to handle and transport. It also offers excellent recyclability, making it an environmentally-friendly choice.

- Q: Can tinplate be used for packaging wine or spirits?

- Yes, tinplate can be used for packaging wine or spirits. Tinplate is a type of steel coated with tin, which provides excellent protection against corrosion and can preserve the quality and flavor of the wine or spirits. Additionally, tinplate is lightweight and easy to shape, making it a suitable choice for packaging various alcoholic beverages.

- Q: What are the regulations and standards related to tinplate packaging?

- Regulations and standards related to tinplate packaging may vary depending on the specific country or region. However, in general, tinplate packaging is subject to regulations and standards related to food safety, product labeling, and environmental concerns. These regulations ensure that tinplate packaging materials are safe for food contact and that they comply with specific guidelines for packaging materials. Additionally, there may be standards regarding the thickness, coating, and overall quality of tinplate packaging to ensure its durability and performance.

- Q: What is the cost of tinplate compared to other packaging materials?

- The cost of tinplate is generally higher compared to other packaging materials such as aluminum, paper, or plastic. Tinplate is a durable and versatile material, but its higher cost is primarily due to the production process involving coating steel with a thin layer of tin. While other materials may offer a more cost-effective solution for certain applications, tinplate's unique properties and premium image make it a preferred choice for certain industries like food and beverages, cosmetics, and pharmaceuticals. Ultimately, the cost of tinplate should be evaluated in relation to the specific needs and requirements of the packaging project.

- Q: What are the common forms of corrosion that affect tinplate?

- Tinplate commonly experiences three forms of corrosion: uniform corrosion, pitting corrosion, and tin whisker growth. Uniform corrosion occurs evenly across the surface, leading to a thinning of the tin coating. Pitting corrosion, on the other hand, creates localized holes or pits, compromising the integrity of the tinplate. Lastly, tin whisker growth involves the formation of tiny, crystalline structures that can lead to short-circuits or other electrical issues.

- Q: How does tinplate affect the cost of packaging?

- Tinplate can increase the cost of packaging due to its higher manufacturing and material expenses compared to other packaging materials such as aluminum or plastic. However, it offers various benefits like excellent durability, corrosion resistance, and ability to keep the contents fresh, which can justify the higher cost for certain products.

- Q: Can tinplate be used for packaging electronic components?

- Yes, tinplate can be used for packaging electronic components. Tinplate is a material made from thin sheets of steel coated with a layer of tin, which provides excellent corrosion resistance and electrical conductivity. It is commonly used in the packaging industry for various applications, including packaging electronic components. The tin coating protects the components from moisture and other environmental factors, ensuring their safety and longevity. Additionally, tinplate offers good formability, making it suitable for creating customized packaging shapes to accommodate different electronic components.

- Q: Can tinplate be formed into different shapes and sizes?

- Yes, tinplate can be easily formed into various shapes and sizes due to its malleability and flexibility.

- Q: What are the main applications of tinplate in the automotive industry?

- Tinplate is primarily used in the automotive industry for various applications such as fuel tanks, engine covers, battery casings, and other components that require corrosion resistance and durability. It provides protection against rust and enhances the overall aesthetic appeal of these parts.

Send your message to us

Electrolytic Tinplate Food Can Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords