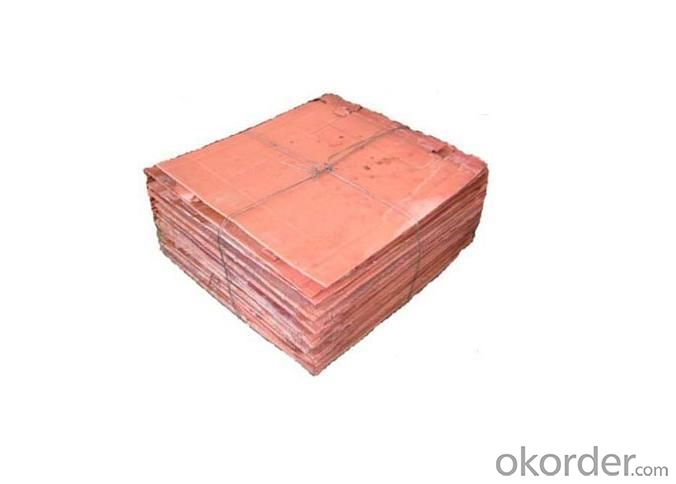

Electrolytic Copper with Factory Outlet Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Kilograms kg

- Supply Capability:

- 50000000 Kilograms per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

purity: 99.7%min

particle size:-250 Mesh

loose density:<=1.76g/cm3

factory outlet price...

1,High-conductivity oxygen-free copper

2,For wire and cable

3,Thickness :0.1-0 .8 mm

4,Width :20-420mm Copperbelt Specification

TU1 TU2(T2) C10200 C1020

Quality standard Depth 0.1mm-0.8mm

Width ≤420mm

Length ≤5000m

Side camber ≤150mm/n

Hardness 55HV-100HV

Eiectic conductivity ≥100%

Tensile Strenhth ≥195MPA

Eiongation ≥40%

Resistance ≤0.01724

Oxygen Content ≤0.0008%

Cu.Purity ≥99.97%

- Q: What is the raw material used in the production of plastic products?

- The poisonous and harmful substances produced by plastics of this kind of material come from 2 aspects. One is the single molecule vinyl chloride which is not completely polymerized in the process of production, and the other is the harmful substance in the plasticizer (two). These 2 substances in the high temperature and fat when easy to precipitate, toxic substances enter the human body with food, easy to cause cancer. At present, the containers for this material are less used for packaged food. If the family has this kind of material, don't let it heat.

- Q: What kind of material is the plastic bag commonly used in supermarkets now?

- 1. HDPE is a shopping bag for supermarkets. It feels cool and hard to use. Do not add color, the bag is very dim.2. low density polyethylene, used for packaged food, feels soft and transparent.

- Q: What is the difference between PA66 and PA6 plastic raw materials? Differences in price, color, performance, etc

- PA66 (polyamide 66 or nylon 66) is more widely used in the automotive industry, instrument shells, and other products that require impact resistance and high strength than PA6, PA66.

- Q: What material is plastic bag made of?

- Shrinkfilm-- shrink film (Shrinkfilm) is a thermoplastic film that is stretched during production, contracted, and subjected to thermal air treatment or infrared irradiation during use. After heat treatment, the film is wrapped tightly in the package, and the shrinkage force reaches the maximum value in the cooling stage and can be stored for a long time. LDPE-- low density polyethylene (LDPE), low density polyethylene (HDPE), or LDPE, is the most widely used plastic packaging and printing industry in many countries. The specific gravity is 0.92 ~ 0.93, and can float in water. Low crystallinity (60%), under the pressure of 1000 ~ 3000kg/C square meters of bulk polymerization of high pressure polyethylene. At 23 degrees centigrade, the density is about 0.92. It is difficult to roll forming and is suitable for tubular films. Applicable to food packaging, fiber packaging, daily necessities packaging. Degradable plastic bags mark

- Q: What is the difference between PP raw material and modified PP?

- PP raw materials refer to resinsConcept: the word "plastic" in the word "plastic material" is intended as a material or plastic material that can be arbitrarily shaped into various shapes. In the dictionary is defined as "synthetic or natural polymers as the main component, under certain conditions can plasticization and molding can keep shape, the end product of materials.

- Q: What plastic material is used for plastic hose?

- PP: good corrosion resistance, high strength, high surface hardness, good surface finish, have certain resistance to high temperature hot melt welding, flange connecting thread, sea water, oil and chemical sewage irrigation pipe, concrete floor for indoor heating system for heating pipe

- Q: What plastic material is resistant to high temperature?

- PPS is a kind of special engineering plastics with excellent comprehensive performance. Dimensional stability of PPS has excellent temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced and excellent physical and mechanical properties and excellent electrical properties and other characteristics, are widely used as structural polymer materials, by filling after modification, widely used in special engineering plastics. At the same time, it can be made into various functional films, coatings and composite materials. It has been successfully applied in the fields of electronics, electrical appliances, aeronautics and Astronautics, automobile transportation and so on. Domestic enterprises have actively developed and formed a certain production capacity, which changed the situation of relying solely on imports in the past. However, there are still some problems in China's PPS technology, such as low variety of products, high functional products, and urgent expansion of production capacity, which will be the focus of the next development of PPS.

- Q: What are the criteria for the classification of plastic materials at injection molding and extrusion?

- In comparison, the lower melt flow rate is applicable to the extrusion grade, and the higher is applicable to the injection molding grade. As to what is low and what is high, there is a difference between the different plastic varieties.

- Q: How about the price of plastic raw materials now?

- Businesses still adhere to prudent operation, mainly with quotations in the market, and more wait-and-see mentality.

- Q: Chemical, plastic raw materials, plastic raw materials how sub grade?

- That's because the raw material used for making plastic barrels is different. Just like the quality of the clothes, the grades of the fabrics used are different, and the products presented are definitely different.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | Above US$100 Million |

| Main Markets | 40.00% Africa 20.00% South America 10.00% Southeast Asia 10.00% Mid East 10.00% North America 10.00% Eastern Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | percent of export |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | average |

Send your message to us

Electrolytic Copper with Factory Outlet Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Kilograms kg

- Supply Capability:

- 50000000 Kilograms per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords